Mar . 07, 2025 06:32 Back to list

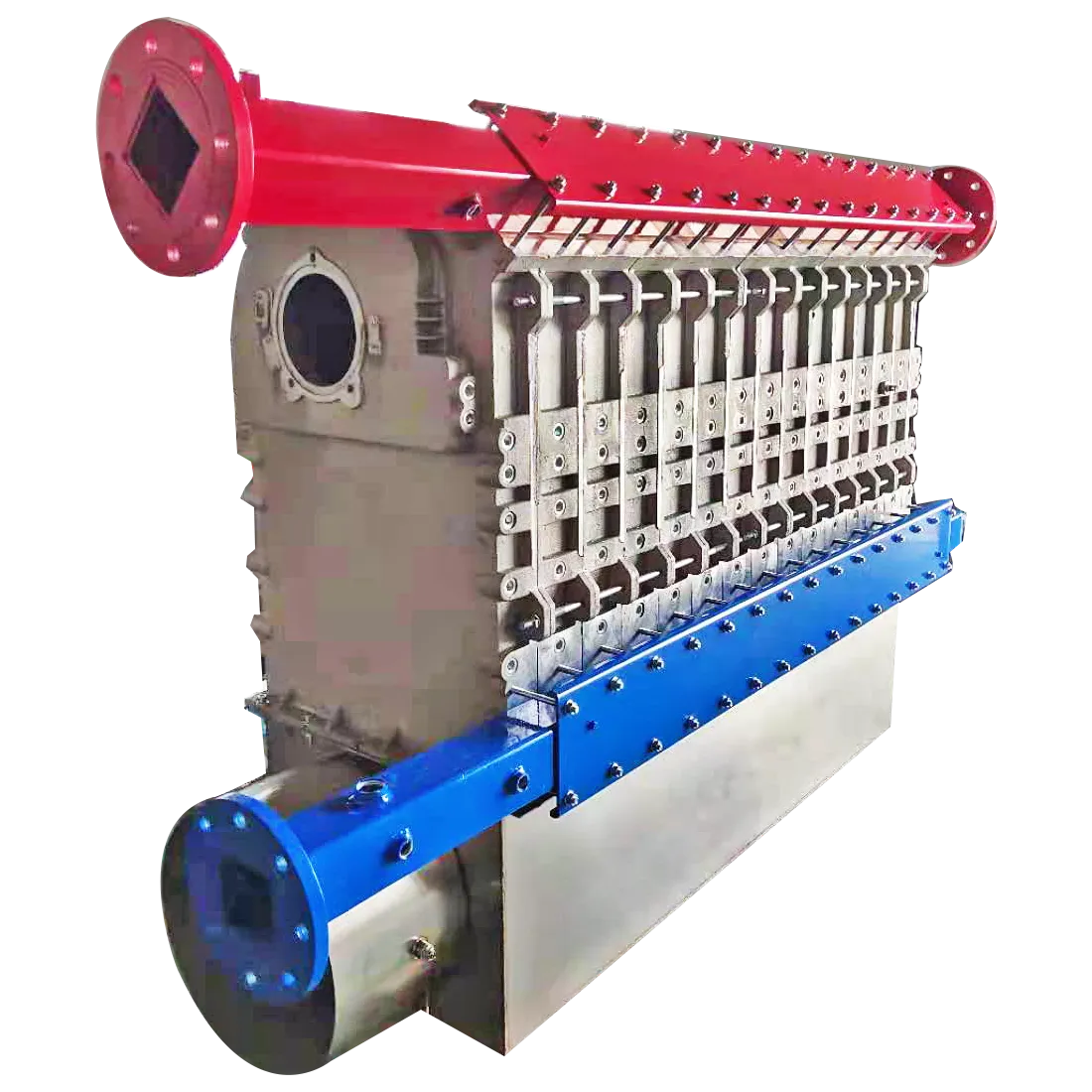

Low Nitrogen Condensing Gas-Fired Boiler

Understanding the factors influencing commercial oil-fired boilers prices can be pivotal for businesses seeking cost-effective and efficient heating solutions. The investment in an oil-fired boiler is not merely about the upfront cost but involves a comprehensive evaluation of performance, longevity, and operational efficiency. This article delves into the essential elements that businesses must consider, offering insights drawn from industry expertise and credible experiences.

Installation costs also contribute heavily to the total expense of acquiring a commercial oil-fired boiler. Proper installation is crucial for optimal performance and longevity, requiring skilled technicians with certification and experience. Poor installation can lead to operational inefficiencies and increased maintenance needs, underscoring the importance of hiring professionals. Industry insiders advise budgeting for quality installation services as part of the full cost consideration. Moreover, the regulatory environment and local fuel prices are external factors that can influence the cost dynamics of operating an oil-fired boiler. Regions with stricter emissions regulations may necessitate additional features like emissions controls, thus affecting boiler specifications and price. Similarly, variable oil prices locally can alter fuel cost forecasts, impacting the calculated operating expenses of oil-fired systems. Finally, the total cost of ownership should be a primary consideration. This includes the initial purchase, installation, ongoing operating expenses, maintenance, and eventual disposal costs. Businesses are encouraged to look beyond the sticker price and evaluate the boiler’s efficiency, maintenance requirements, expected lifespan, and manufacturer support services. In conclusion, the pricing of commercial oil-fired boilers is a multifaceted subject where numerous variables interact. While upfront cost is a critical factor, the overall value comes from a comprehensive understanding of how each aspect influences long-term operational efficiency and cost-effectiveness. Engaging with industry professionals and consulting with reputable manufacturers can guide businesses toward making informed, strategic investments in their heating infrastructure, ensuring both cost savings and reliable service.

Installation costs also contribute heavily to the total expense of acquiring a commercial oil-fired boiler. Proper installation is crucial for optimal performance and longevity, requiring skilled technicians with certification and experience. Poor installation can lead to operational inefficiencies and increased maintenance needs, underscoring the importance of hiring professionals. Industry insiders advise budgeting for quality installation services as part of the full cost consideration. Moreover, the regulatory environment and local fuel prices are external factors that can influence the cost dynamics of operating an oil-fired boiler. Regions with stricter emissions regulations may necessitate additional features like emissions controls, thus affecting boiler specifications and price. Similarly, variable oil prices locally can alter fuel cost forecasts, impacting the calculated operating expenses of oil-fired systems. Finally, the total cost of ownership should be a primary consideration. This includes the initial purchase, installation, ongoing operating expenses, maintenance, and eventual disposal costs. Businesses are encouraged to look beyond the sticker price and evaluate the boiler’s efficiency, maintenance requirements, expected lifespan, and manufacturer support services. In conclusion, the pricing of commercial oil-fired boilers is a multifaceted subject where numerous variables interact. While upfront cost is a critical factor, the overall value comes from a comprehensive understanding of how each aspect influences long-term operational efficiency and cost-effectiveness. Engaging with industry professionals and consulting with reputable manufacturers can guide businesses toward making informed, strategic investments in their heating infrastructure, ensuring both cost savings and reliable service.

Share

Pervious:

Next:

Latest news

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025

-

Durable Cast Iron Water Main Pipe | Buy Ductile Pipe

NewsAug.06,2025