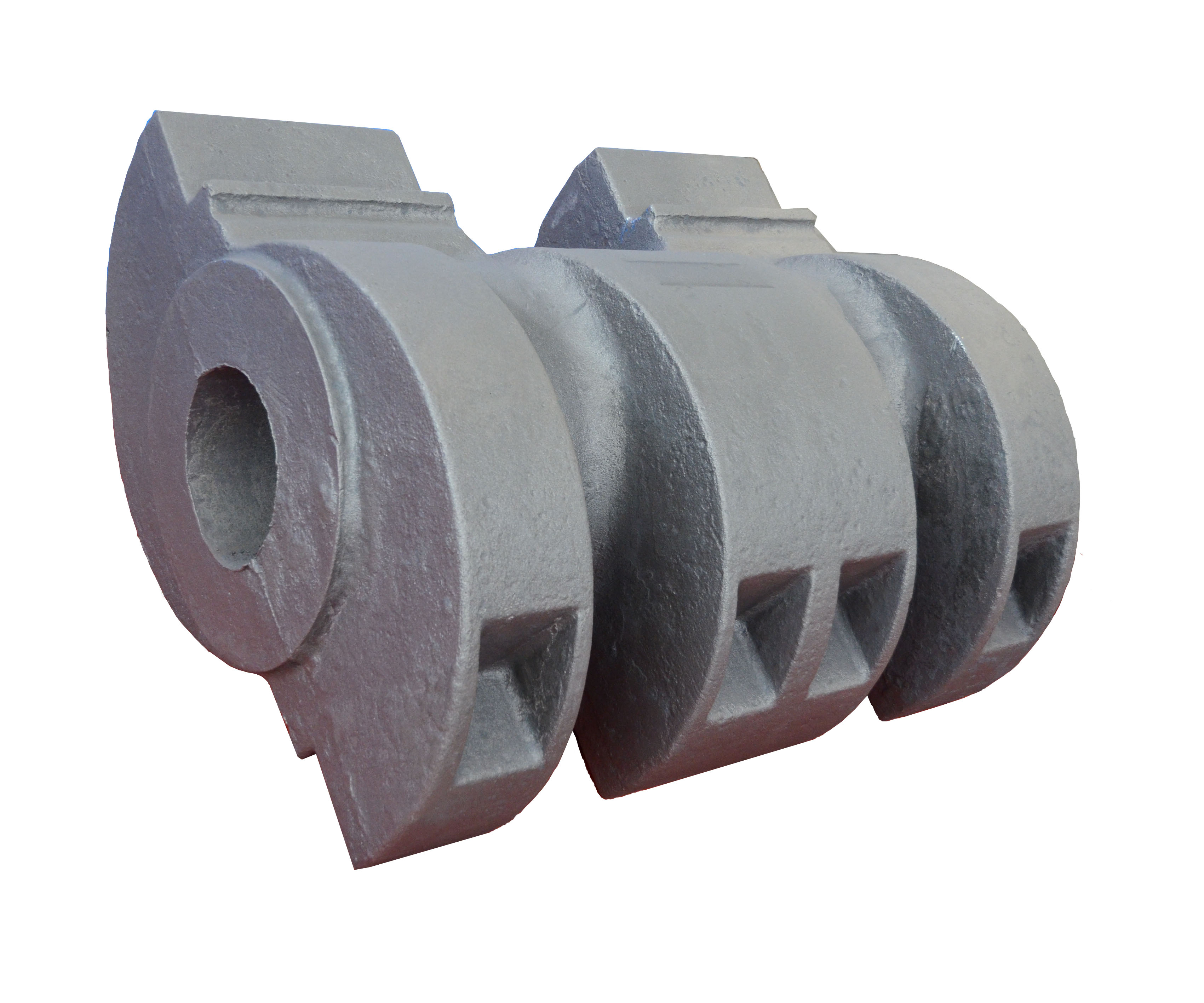

Accessory for Coal/Mine Crusher Made in Cast Steel China Source Factory Supply

Product Description

Main material: Low-carbon ferrochrome, low-carbon ferromanganese, high-grade cast steel, molybdenum, vanadium, and other elements

Casting process: Ester hardened sodium silicate sand casting

Applicable materials: river pebble, granite, basalt, iron ore, limestone, quartz stone, iron ore, gold ore, copper ore, etc.

Application scope: Mining machinery hammer crusher, box hammer crusher, mobile hammer crusher, heavy hammer crusher, etc.

The accessory for the crushing machine is made of ultra-high manganese steel (Mn18Cr2). According to the high-speed operation of the hammer crusher rotor during the use of mining equipment, the stone wears the outer ring of the machine rotor hammer disc when feeding, our factory independently developed and launched the ultra-high manganese steel rotor guard ring because it uses ultra-high manganese steel with a manganese content of 15.5%-18% while adding chromium, molybdenum, vanadium and other metal elements to improve its yield strength and initial hardness. , Thus effectively prolonging the service life of the rotor hammer disc of the machine, and obtaining a very good use effect in actual production. Moreover, with the continuous development of wear-resistant materials, the service life of the ultra-high manganese steel rotor retainer produced by our factory is 40%-50% longer than that of an ordinary high manganese steel rotor retainer.

The wear-resistant parts of the crusher are generally cast from steel, and the service life needs to be determined by the hardness and quantity of the crushed material. If it crushes hard material, such as minerals, ironware, glass, etc., the service life of worn parts will be shortened; if it is crushed hard, such as kitchen waste, or household garbage, the service life will be longer.

Molten Steel Is Being Melted

|

|

|

|

|