- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Okt . 19, 2024 05:35 Back to list

coal minning machinery casting exporters

The Role of Foundries in Coal Mining Machinery Production

In the global supply chain of coal mining, machinery plays a crucial role in ensuring efficiency, productivity, and safety in mining operations

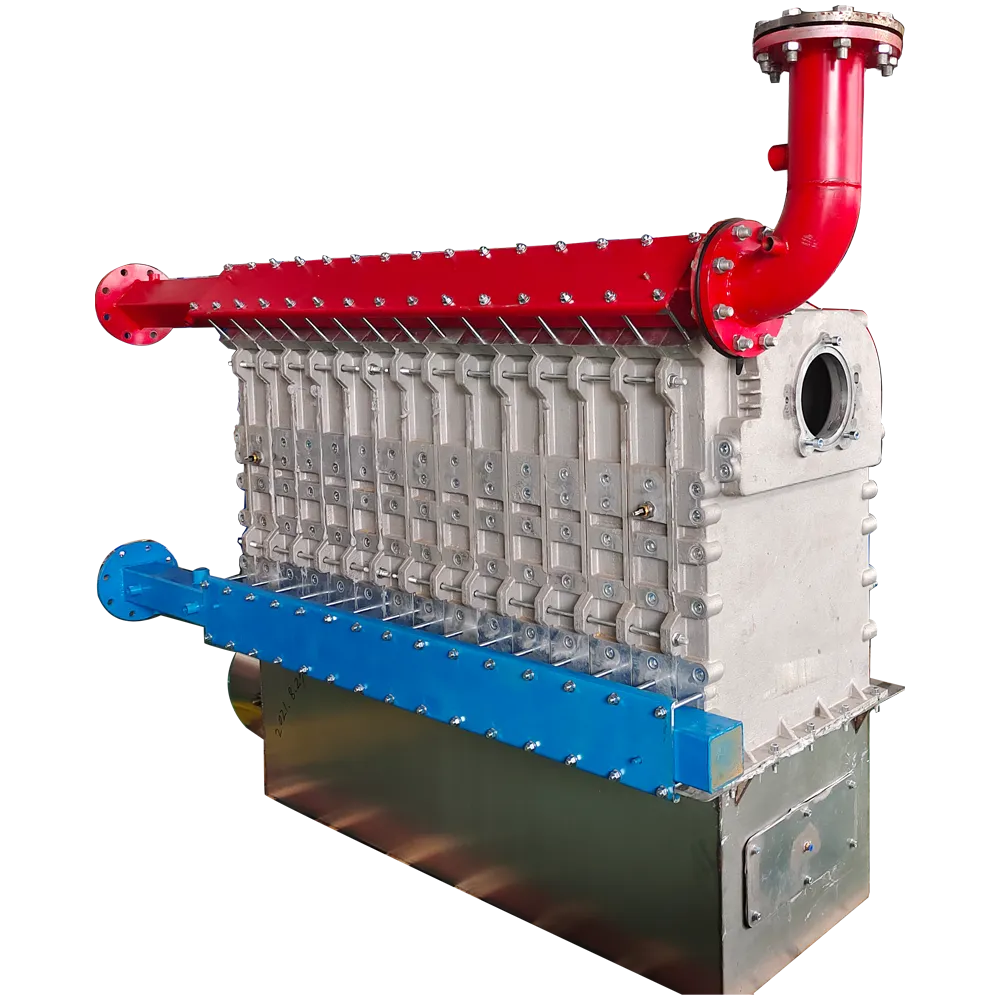

. Among the essential components in manufacturing this machinery are the specialized castings produced by foundries, which have increasingly become significant exporters in the industry.Coal mining machinery encompasses a range of equipment, including excavators, draglines, shuttle cars, and continuous miners. Each of these machines requires robust and durable components capable of withstanding the harsh conditions of mining environments. This is where casting comes into play. Foundries are responsible for producing high-quality cast iron, steel, and other alloy castings that constitute the backbone of these machines.

The casting process involves pouring molten metal into molds to create a wide variety of shapes and sizes tailored to specific machinery requirements. Foundries that specialize in coal mining machinery casting utilize advanced technologies such as computer-aided design (CAD) and computer-aided manufacturing (CAM) to ensure precision and quality. This technological edge not only improves efficiency in production but also enhances the mechanical properties of the castings, leading to improved longevity and performance of mining equipment.

coal minning machinery casting exporters

As the demand for coal remains significant in many regions, particularly in developing economies, the need for reliable and efficient mining machinery continues to grow. Consequently, exporters of coal mining machinery castings play a vital role in meeting this demand. They supply not only local markets but also international markets, contributing to the global mining machinery supply chain. As industries move toward automation and advanced technology, these foundries are adapting by focusing on research and development to innovate and produce lighter, stronger, and more efficient cast components.

However, the industry faces challenges. Environmental regulations and the increasing shift toward sustainable energy sources are altering the landscape of coal production. Foundries must navigate these challenges by adopting environmentally friendly practices in their casting processes, such as recycling scrap metal and implementing energy-efficient technologies. Furthermore, they are also exploring the production of components for renewable energy applications, thereby diversifying their portfolios and securing future growth.

In conclusion, foundries engaged in the casting of coal mining machinery are pivotal in supporting the mining industry. Their role as exporters not only facilitates the availability of critical machinery components but also contributes to advancements in mining technology. As the industry evolves, these foundries will require innovation, adaptability, and a commitment to sustainability to thrive in an ever-changing environment. By embracing these challenges, they can continue to be key players in the global coal mining landscape.

-

Durable Cast Iron Water Main Pipe | AI-Optimized Design

NewsAug.05,2025

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025