- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Des . 11, 2024 09:57 Back to list

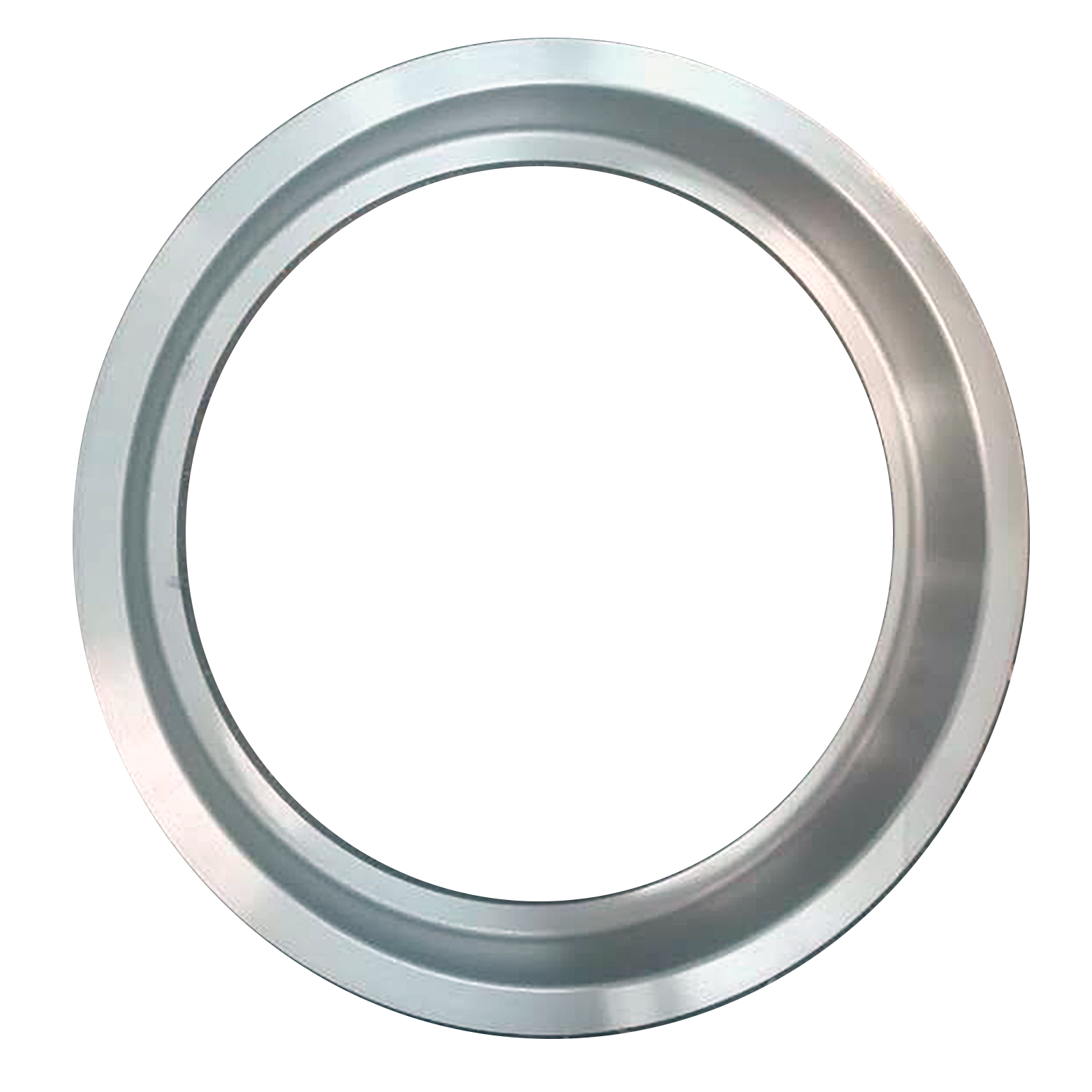

Concrete Pipe Mold Base Ring Design for Efficient Production Techniques

Understanding the Importance of Concrete Pipe Mold Bottom Rings

Concrete pipes have been an essential component in various construction and infrastructure projects, serving roles in drainage, sewage systems, and even as structural elements in buildings. The efficiency and durability of these pipes largely depend on the quality of molds used in their production. Among the components of these molds, the bottom ring plays a crucial role, influencing not only the shape and integrity of the pipe but also the overall production process.

The Function of Bottom Rings

Concrete pipe mold bottom rings are integral to the mold assembly. They are designed to create a stable base upon which concrete can be poured to form the pipes. The bottom ring ensures that the shape of the pipe remains consistent while the concrete sets, which is essential for achieving the required specifications and dimensions. Without a well-constructed bottom ring, the shape of the pipe could become distorted, leading to structural inefficiencies and increased production costs.

Material Considerations

The choice of materials for manufacturing bottom rings is vital. Typically, these rings are made from high-strength steel or reinforced plastics, designed to withstand the weight of the concrete and the pressure exerted during curing. The durability of the material also ensures that the mold can be reused multiple times without significant wear and tear, thus offering cost-effectiveness and sustainability in the mold-making process.

Design and Precision Engineering

The design of the bottom ring must account for the specific requirements of the concrete being used. Factors such as the diameter of the pipe, the thickness of the walls, and the expected pressure during service must all be considered. Advanced engineering techniques, including computer-aided design (CAD), allow manufacturers to create precision molds that can produce pipes to exact specifications, reducing waste and ensuring consistency.

src concrete pipe mold bottom ring

The Production Process

In the production of concrete pipes, the bottom ring is first placed in the mold assembly. Concrete is then poured into the mold, filling the cavity created by the bottom ring and the sides of the mold. As the concrete sets, the bottom ring provides stability, ensuring that the base of the pipe forms correctly. Once the curing process is complete, the mold can be removed, and the finished pipe can be inspected for quality.

The Impact on Quality Control

Quality control is a crucial aspect of concrete pipe production, and the bottom ring significantly impacts this process. A well-designed bottom ring will help in achieving uniform thickness and proper dimensions, which are essential for ensuring that the pipes meet industry standards. Additionally, the smooth surface created by the bottom ring can reduce the likelihood of defects in the final product.

Innovations in Bottom Ring Design

Recent advancements in mold technology have led to innovations in bottom ring designs, including interchangeable bottom rings that can adapt to different pipe sizes and specifications. This flexibility can streamline the production process and reduce the need for multiple molds, ultimately saving time and resources.

Conclusion

The concrete pipe mold bottom ring is a seemingly small component that plays an outsized role in the production of concrete pipes. Its significance lies in its ability to provide stability, ensure design precision, and contribute to the overall quality of the final product. As technology advances, the design and materials used for bottom rings are likely to continue evolving, further enhancing the efficiency and effectiveness of concrete pipe production. In an industry where quality and performance are paramount, investing in superior bottom ring designs will undoubtedly lead to better outcomes for construction projects worldwide.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025