- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ኅዳር . 15, 2024 15:57 Back to list

custom bronze investment casting

Custom Bronze Investment Casting A Craft of Precision and Excellence

Investment casting, also known as lost-wax casting, is a method of metalworking that has been used for centuries to create intricate and precise parts. Among the various metals that can be cast, bronze stands out for its durability, corrosion resistance, and aesthetic appeal. Custom bronze investment casting, in particular, combines the artistry of skilled craftsmen with advanced technology to produce components that meet the unique specifications of different industries.

The Investment Casting Process

The investment casting process begins with the creation of a wax model of the desired part. This model is then coated in a fine ceramic material to form a shell. Once the shell hardens, the wax is melted away—hence the term lost-wax casting—leaving a precise mold for the bronze to be poured into. The molten bronze is subsequently introduced into the mold and allowed to cool and solidify. After cooling, the ceramic shell is removed, revealing the intricately detailed bronze casting.

This method is particularly advantageous for producing complex geometries that would be difficult or impossible to achieve with traditional casting methods. The smooth surfaces and fine details achieved through investment casting often eliminate the need for extensive machining, thereby saving time and reducing waste.

Applications of Custom Bronze Investment Casting

Custom bronze investment casting finds applications across various sectors, including aerospace, automotive, marine, and ornamental design. In the aerospace industry, for instance, precision parts such as turbine blades and housings are often made from bronze due to its durability and ability to withstand extreme conditions. The automotive industry also benefits from bronze components in engine parts, bushings, and fittings that require high wear resistance.

In the marine sector, bronze is favored for its ability to resist corrosion in saltwater environments, making it an ideal choice for boat fittings, propellers, and other components exposed to harsh conditions. Moreover, artists and designers utilize bronze investment casting to create sculptures, jewelry, and architectural elements that showcase the metal's beauty and versatility.

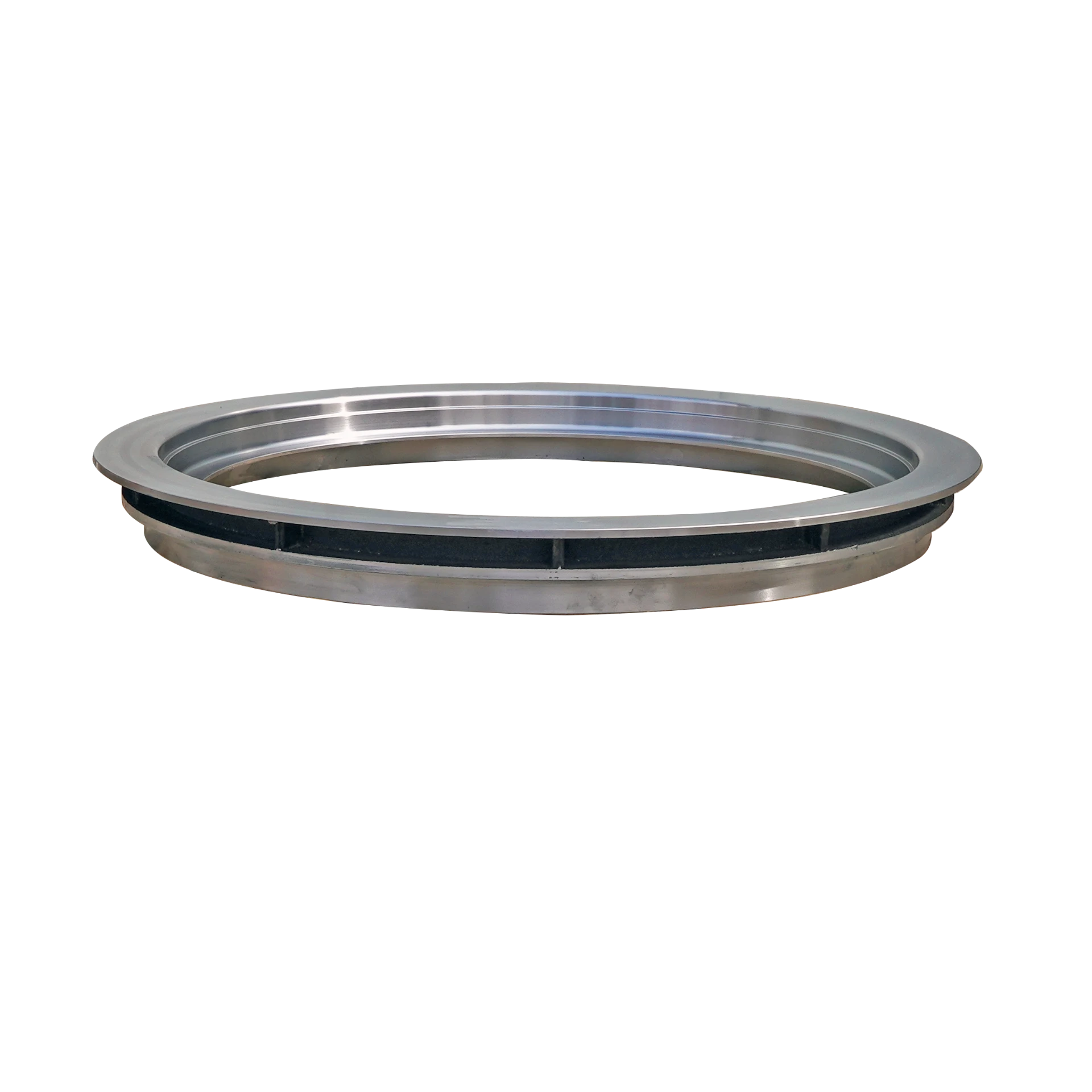

custom bronze investment casting

Benefits of Customization

One of the greatest advantages of custom bronze investment casting is the ability to tailor each part to the specific needs of a project. Manufacturers can work closely with clients to understand their requirements, from dimensions and weight specifications to mechanical properties and surface finishes. This level of customization ensures that the final product not only meets but often exceeds the expectations of the client.

Additionally, advanced technologies like computer-aided design (CAD) allow for precise modeling before production begins. This ensures that potential design flaws can be addressed early in the process, further enhancing the quality and precision of the final bronze casting.

Sustainability and Innovation

As industries increasingly focus on sustainability, the investment casting process and bronze itself offer potential benefits. Bronze is recyclable, and the investment casting process generates less waste compared to other manufacturing methods. Moreover, innovations in casting technology continue to improve efficiency, reduce energy consumption, and lower the overall carbon footprint of production.

Conclusion

Custom bronze investment casting is a remarkable combination of traditional craftsmanship and modern technology. This method not only allows for the creation of intricate and durable parts but also fosters innovation and sustainability in today’s manufacturing landscape. Whether it’s for aerospace components, marine fittings, or artistic designs, the versatility and reliability of custom bronze investment casting make it an indispensable resource across various industries. The precision, aesthetic quality, and practical benefits of bronze castings promise a bright future for this timeless technique in the rapidly evolving world of manufacturing.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025