- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

يناير . 11, 2025 09:32 Back to list

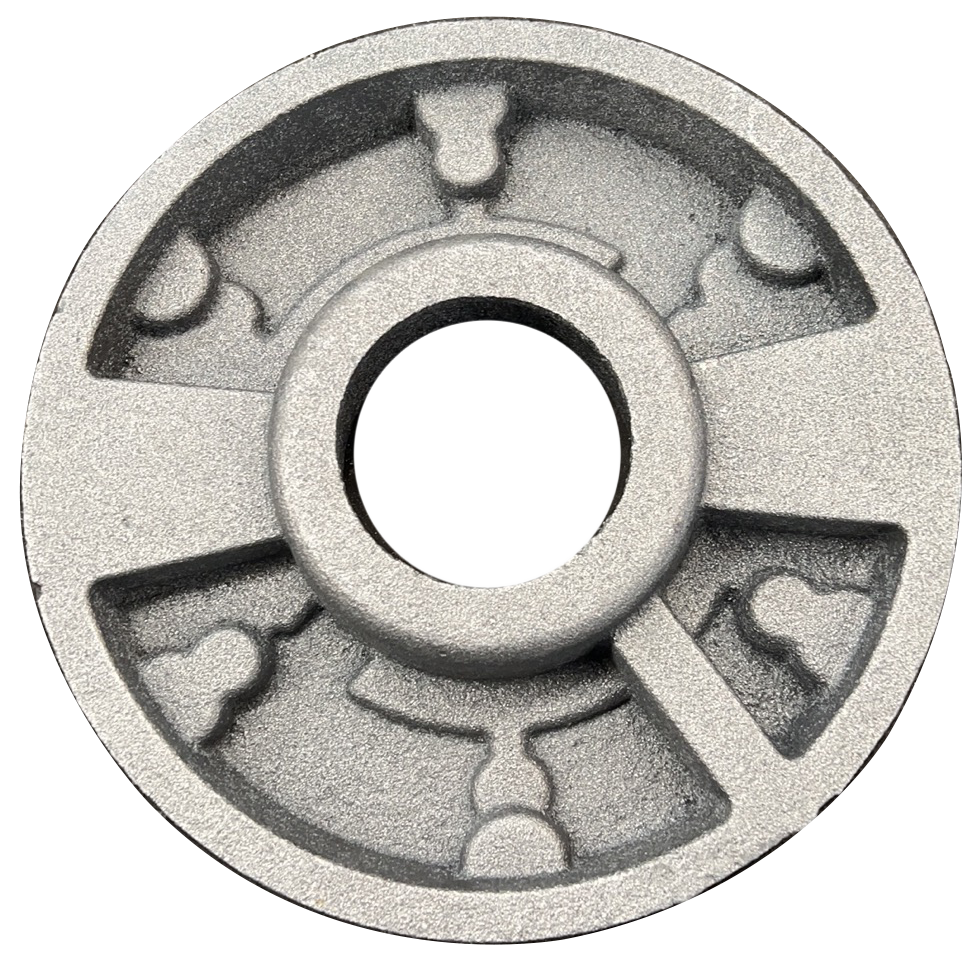

punch cement pipe mould pallet

Using innovative construction techniques can pave the way for revolutionizing the industry. One of the pivotal developments in recent times is the use of punch cement pipe mould pallets. These specialized tools are transforming the way we approach concrete pipe manufacturing, providing tangible benefits in efficiency, durability, and cost-effectiveness.

In terms of authoritativeness, the use of punch cement pipe mould pallets is supported by extensive research and field tests conducted by leading institutions in civil engineering and construction technology. Studies have shown that pipes produced using these pallets exhibit enhanced load-bearing capacity and resilience against environmental stressors such as moisture and temperature variation. This is due to the precise compression and reduced air pockets within the mould, which contribute to the overall density and homogeneity of the concrete. Trustworthiness is a cornerstone of any reputable manufacturing process. The punch cement pipe mould pallet not only inspires confidence through its innovative design and proven track record but also through its adherence to industry standards and regulations. Manufacturers who adopt this technology demonstrate a commitment to quality assurance, offering pipes that are rigorously tested and certified to meet or exceed required specifications. This commitment ensures that clients and stakeholders can trust in the infrastructure developed using these components. In conclusion, punch cement pipe mould pallets are not just a trend but a vital tool reshaping the landscape of concrete pipe manufacturing. They bring authentic experience, require a high level of expertise, are backed by authoritative research, and build trust through rigorous adherence to quality and safety standards. As infrastructure demands continue to rise globally, the innovative use of these pallets positions companies at the forefront of a competitive industry, promising not only quality but also sustainability and efficiency in their operations. By leveraging these pallets, manufacturers are well-equipped to face the evolving challenges of modern infrastructure needs.

In terms of authoritativeness, the use of punch cement pipe mould pallets is supported by extensive research and field tests conducted by leading institutions in civil engineering and construction technology. Studies have shown that pipes produced using these pallets exhibit enhanced load-bearing capacity and resilience against environmental stressors such as moisture and temperature variation. This is due to the precise compression and reduced air pockets within the mould, which contribute to the overall density and homogeneity of the concrete. Trustworthiness is a cornerstone of any reputable manufacturing process. The punch cement pipe mould pallet not only inspires confidence through its innovative design and proven track record but also through its adherence to industry standards and regulations. Manufacturers who adopt this technology demonstrate a commitment to quality assurance, offering pipes that are rigorously tested and certified to meet or exceed required specifications. This commitment ensures that clients and stakeholders can trust in the infrastructure developed using these components. In conclusion, punch cement pipe mould pallets are not just a trend but a vital tool reshaping the landscape of concrete pipe manufacturing. They bring authentic experience, require a high level of expertise, are backed by authoritative research, and build trust through rigorous adherence to quality and safety standards. As infrastructure demands continue to rise globally, the innovative use of these pallets positions companies at the forefront of a competitive industry, promising not only quality but also sustainability and efficiency in their operations. By leveraging these pallets, manufacturers are well-equipped to face the evolving challenges of modern infrastructure needs.

Share

Pervious:

Latest news

-

Durable Cast Iron Water Main Pipe | AI-Optimized Design

NewsAug.05,2025

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025