- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Noy . 13, 2024 19:32 Back to list

ductile iron cement pipe mold pallet factories

Ductile Iron Cement Pipe Mold Pallet Factories An Overview

Ductile iron cement pipes are a cornerstone of modern infrastructure, utilized extensively for water and wastewater management due to their strength, durability, and corrosion resistance. The manufacturing process of these pipes involves various stages, including the use of mold pallets that play a critical role in shaping and forming the pipes. In this article, we will delve into the significance of ductile iron cement pipe mold pallet factories, their operations, and their impact on the industry.

Understanding Ductile Iron Cement Pipes

Ductile iron, an alloy of iron with small amounts of carbon and silicon, exhibits remarkable mechanical properties. It offers increased tensile strength, making it an ideal choice for applications that require durability and resistance to stress and environmental challenges. When combined with a cement lining, these pipes can withstand harsh conditions while maintaining structural integrity. Consequently, ductile iron cement pipes are commonly used for water distribution, sewer systems, and industrial applications.

The Role of Mold Pallets

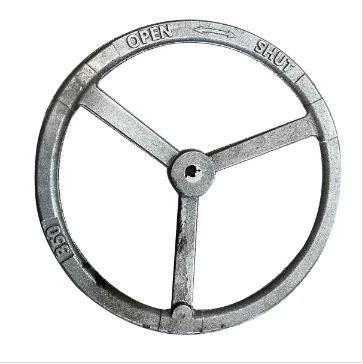

Mold pallets are essential tools in the manufacturing of ductile iron cement pipes. They provide the necessary shape and support during the production process. Typically made from high-quality materials such as reinforced steel or aluminum, these pallets are designed to withstand the high temperatures and pressures associated with the casting and curing processes.

The molds created using these pallets must meet precise specifications to ensure uniformity in the pipe's dimensions and performance characteristics. The quality of mold pallets directly impacts the efficiency of the manufacturing process, as well as the final product's quality.

The Manufacturing Process

The production of ductile iron cement pipes begins with the preparation of the raw materials, including the iron, graphite, and other alloying elements. The prepared materials are then melted in high-temperature furnaces, and the molten iron is poured into molds created from the pallets.

ductile iron cement pipe mold pallet factories

Once the molten iron cools and solidifies, the pipes are subjected to a series of inspections and tests to ensure they meet stringent industry standards. After the initial casting, the pipes are lined with cement, which enhances their resistance to corrosion and extends their service life. This entire process requires precision and attention to detail, where mold pallets play a crucial role.

The Importance of Factories

Mold pallet factories specialize in producing these critical components. These factories focus on designing and manufacturing mold pallets that are robust, precise, and tailored to fit the specific requirements of ductile iron cement pipe production. The process involves advanced engineering techniques, including computer-aided design (CAD), which allows for the creation of molds that optimize both performance and durability.

Additionally, these factories must adhere to strict quality control measures to ensure that the mold pallets can withstand repeated use in high-pressure environments. From material selection to production processes, every aspect is meticulously monitored to maintain high standards of quality.

Technological Advancements

The industry has seen significant advancements in mold pallet design and manufacturing. Innovations such as 3D printing and automated production lines have improved the efficiency of mold pallet factories, allowing for quicker turnaround times and reduced production costs. Furthermore, the use of advanced materials has led to the development of lighter and stronger mold pallets, enhancing the overall manufacturing process of ductile iron cement pipes.

Conclusion

Ductile iron cement pipe mold pallet factories are integral to the production of high-quality ductile iron pipes, which play a vital role in global infrastructure. Their ability to produce robust, accurate, and efficient molds directly influences the quality of the final product, ensuring that it meets the needs of various applications. As technology continues to evolve, these factories will likely adopt further innovations to enhance efficiency and product quality, ultimately supporting the demand for sustainable and durable infrastructure solutions. The importance of these factories cannot be overstated, as they are key players in the ever-evolving landscape of pipe manufacturing, contributing to the development of resilient urban environments.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025