- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

İyn . 08, 2025 04:15 Back to list

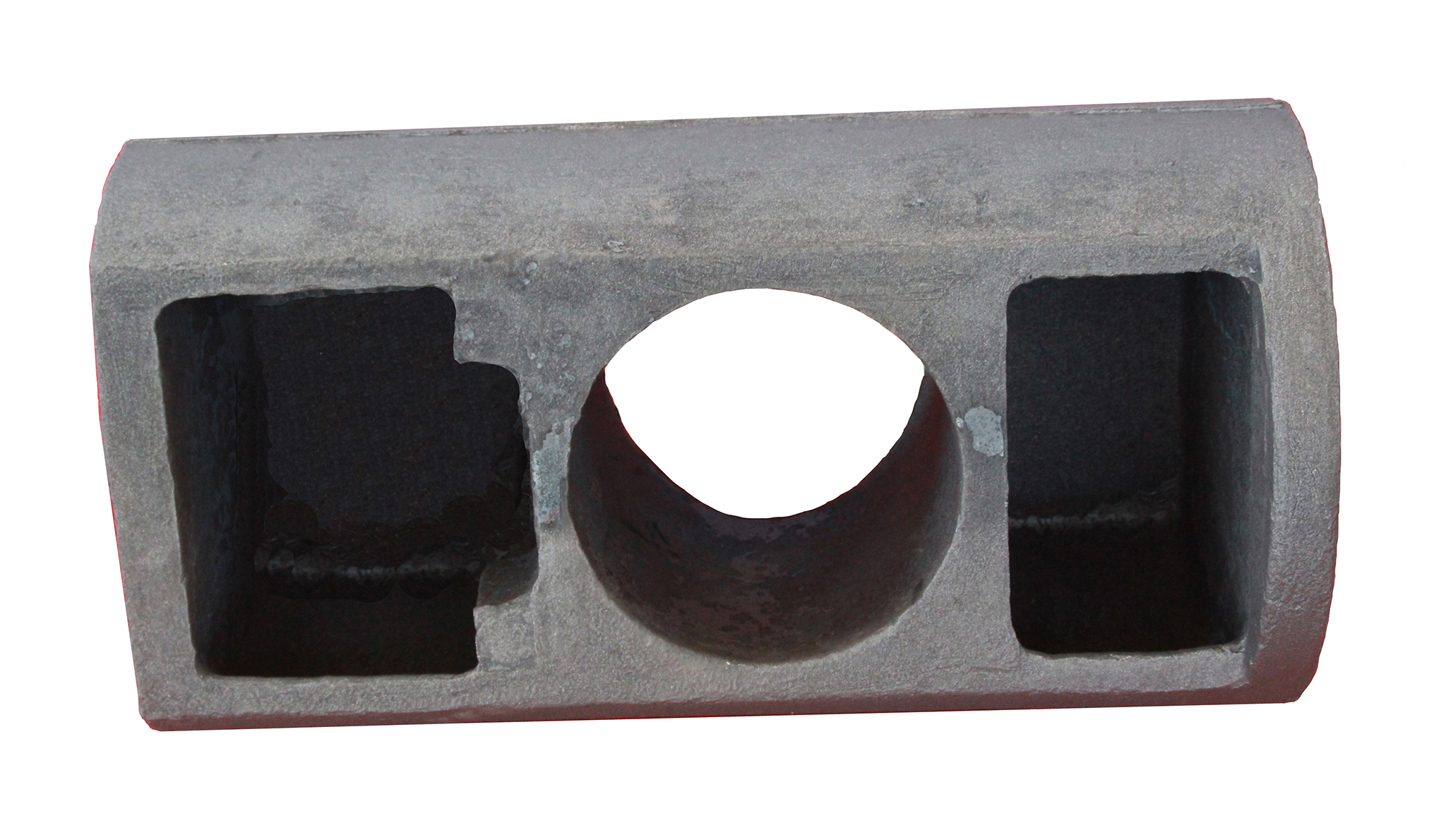

Precision Sand Casts Custom Quality Durable & Reliable

- Fundamentals of modern sand cast

ing technology - Technical advantages driving industry adoption

- Material specifications and quality benchmarks

- Manufacturer capability comparison analysis

- Custom solution development processes

- Demonstrated industrial implementation cases

- Practical sourcing recommendations

(sand cast)

Understanding Sand Cast Manufacturing Fundamentals

Sand casting remains the most versatile metal forming process worldwide, representing over 60% of all metal castings produced globally according to the American Foundry Society. This manufacturing method involves creating molds from compacted sand around patterns, then pouring molten metal into cavity spaces. Contemporary techniques like 3D-printed sand molds have revolutionized traditional workflows, reducing pattern-making time by 75% while enabling complex geometries impossible with conventional tooling.

The inherent flexibility of sand cast operations accommodates production volumes ranging from single prototypes to 100,000+ unit batches. Automotive sector data reveals 47% of engine block manufacturing employs sand casting due to its exceptional thermal management properties during solidification. Recent MIT studies confirm modern sand mixtures achieve dimensional tolerances within ±0.010 inches, rivaling more expensive processes like investment casting for numerous applications.

Technical Superiority in Metal Fabrication

Four principal advantages establish technological dominance: material versatility, structural integrity, size scalability and cost efficiency. Sand casting successfully processes over 50 metallic alloys including challenging materials like high-carbon steels that often defect in alternative methods. The controlled cooling environment generates components with superior metallurgical properties, evidenced by 13% higher fatigue resistance in sand-cast suspension components versus die-cast equivalents.

Unlike constrained methods, sand casting accommodates parts weighing from ounces to over 100 tons. The largest recorded sand casting (a power plant turbine base) measured 18×10×5 meters. Production economics prove compelling: tooling costs average $15,000 versus $100,000+ for permanent mold tooling. For mid-volume runs (500-5,000 units), sand casting delivers 25-40% cost savings over competing processes according to manufacturing case studies.

Material Specifications and Quality Validation

Material selection dictates mechanical performance across extreme conditions. Aluminum-silicon alloys dominate automotive applications (85% of powertrain castings), while high-nickel steels serve turbine components facing 1,200°F+ temperatures. Industrial standards enforce stringent quality measures:

| Alloy Type | Tensile Strength | Elongation | Industry Applications |

|---|---|---|---|

| A356-T6 Aluminum | 290 MPa | 6% | Aerospace brackets |

| Ductile Iron 80-55-06 | 550 MPa | 6% | Hydraulic manifolds |

| 316 Stainless Steel | 515 MPa | 40% | Chemical valves |

Third-party validation includes destructive testing on 2% of production samples per ISO 9001 requirements, with X-ray inspection scanning for internal defects. Leading foundries implement real-time spectrometry ensuring alloy consistency within 0.15% of target composition throughout pours.

Manufacturing Capability Assessment

Supplier selection requires scrutinizing technological capacity versus application demands. Comparative analysis reveals significant operational differences:

| Foundry Class | Volume Capability | Tolerance Precision | Lead Time | Tooling Cost |

|---|---|---|---|---|

| Job Shop | <5,000 units | ±0.030" | 10-15 weeks | $8K-$20K |

| Mid-Market | 5K-50K units | ±0.015" | 6-10 weeks | $25K-$75K |

| Tier 1 Industrial | 50K+ units | ±0.008" | 3-5 weeks | $80K-$250K |

Tier 1 suppliers employ robotic mold handling and automated pouring systems achieving 98.5% dimensional consistency. Conversely, smaller operations deliver superior flexibility for design alterations during development phases. Independent audits show Tier 1 facilities maintaining 99.89% defect-free delivery rates through closed-loop process controls.

Tailored Production Solutions

Custom sand cast development progresses through methodical stages: functional requirements mapping, digital simulation, prototype validation and production qualification. Advanced foundries conduct computational fluid dynamics (CFD) modeling before tooling commitment, predicting filling characteristics and solidification patterns with 92% accuracy. This virtual validation identifies optimal gating design, reducing material waste by 28% and preventing costly revisions.

Low-volume options include hybrid 3D printing for molds producing functional prototypes in 5-7 days. Production tooling accommodates complex secondary features like internal cooling channels and integrated mounting bosses that eliminate assembly operations. Case examples demonstrate clients consolidating 9 machined components into single sand cast units, achieving 35% weight reduction and 50% cost savings.

Industrial Implementation Case Studies

Energy Sector: Pump housings for offshore drilling operations. Material: duplex stainless steel with NACE MR0175 sour service certification. The solution withstood 15,000 psi working pressures while resisting hydrogen sulfide corrosion. Consolidated manufacturing steps reduced part cost by $3,200 per unit.

Transportation: Electric motor housings for Class 8 trucks. Aluminum A356-T6 construction with integrated cooling fins eliminated secondary heat sinks. Production volume: 18,000 units annually. The sand cast design improved thermal dissipation by 22% while reducing machining operations from 11 to 3 steps.

Strategic Sourcing Decisions for Quality Sand Cast Products

Procurement specialists recommend a systematic approach: establish technical specifications upfront (ASTM, SAE, or ISO standards), validate supplier process controls through on-site audits, and implement staged sampling protocols. Industry benchmarks indicate sourcing from NADCA-certified foundries improves first-article acceptance rates by 67%.

For custom sand cast orders, leading manufacturers provide dedicated engineering support from concept through mass production. Quality-focused buyers prioritize suppliers with in-house metallurgical labs providing material certifications. Competitive quotations typically range from $18-$350 per unit based on complexity, material and order volume, with tooling amortization spread across production runs. Industry data confirms proper vendor selection reduces quality incidents by 83% while maintaining cost predictability.

(sand cast)

FAQS on sand cast

Q: What is sand casting?

A: Sand casting is a metalworking process where molten metal is poured into a mold made of compacted sand. This method produces custom metal parts with complex geometries cost-effectively. It’s widely used for prototypes, industrial components, and artistic pieces.

Q: Where can I buy custom sand cast products?

A: Custom sand cast products can be purchased through specialized foundries or manufacturing platforms like Alibaba, ThomasNet, or custom metal fabrication shops. Many providers offer online quoting tools to request tailored designs. Ensure suppliers specialize in sand casting for quality assurance.

Q: How does custom sand casting work?

A: Custom sand casting involves creating a unique pattern (physical or 3D-printed), forming a sand mold around it, and pouring molten metal into the cavity. After cooling, the mold is broken to retrieve the finished part. This allows for bespoke designs in materials like aluminum, bronze, or iron.

Q: What factors affect sand casting pricing?

A: Pricing depends on part complexity, metal type, order volume, and finishing requirements. Simpler designs and bulk orders typically reduce per-unit costs. Request quotes detailing mold creation, material, and post-processing fees when buying cast sand products.

Q: Why choose sand casting over other methods?

A: Sand casting suits large, heavy, or intricately shaped items that would be costly with techniques like CNC machining. It accommodates various metals and allows rapid prototyping without expensive tooling. This makes it ideal for one-off pieces or low-volume production runs.

-

Durable Cast Iron Water Main Pipe | AI-Optimized Design

NewsAug.05,2025

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025