- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Каст . 19, 2024 03:17 Back to list

custom stainless steel casting foundry

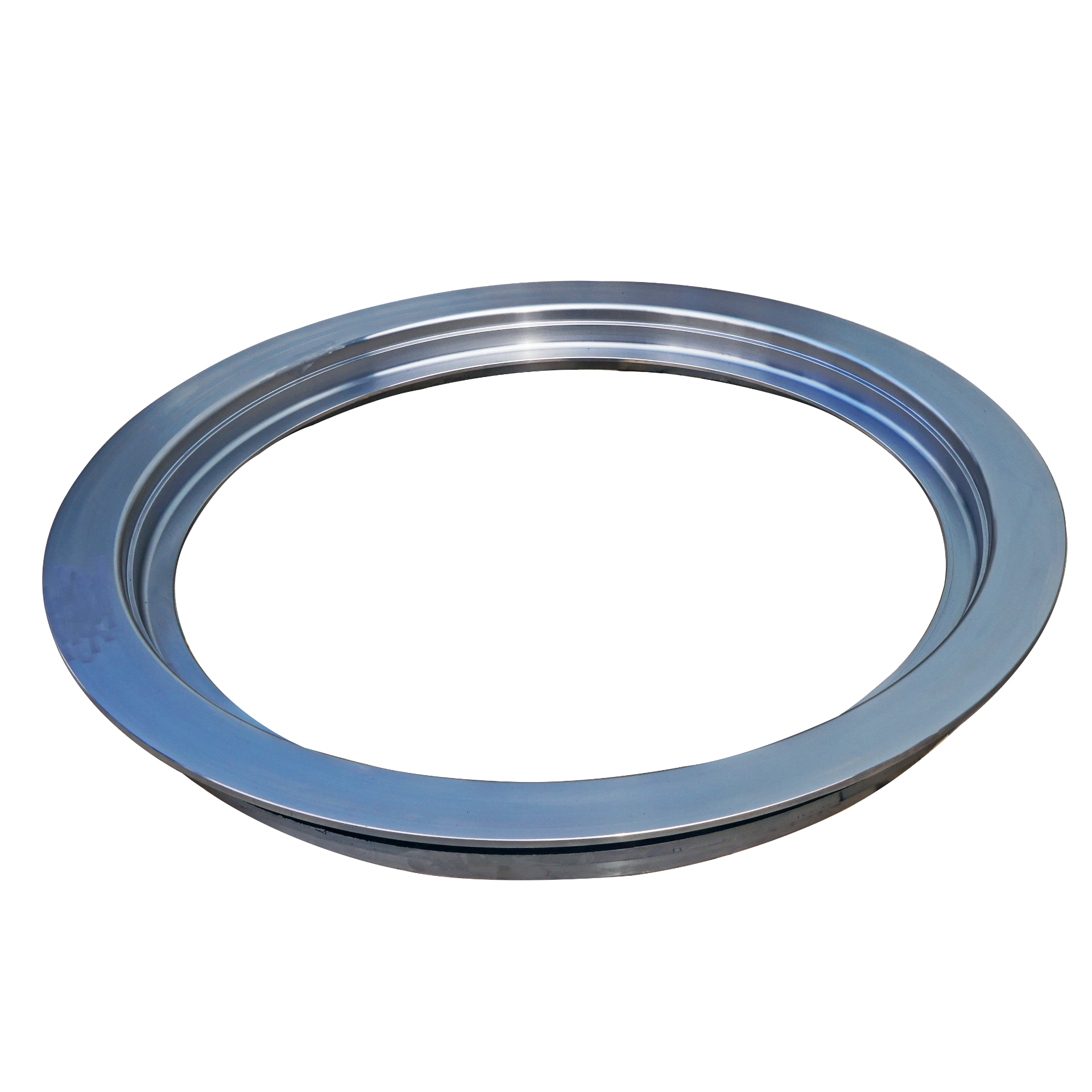

The Art of Custom Stainless Steel Casting A Comprehensive Overview of Foundry Techniques

In the realm of metalworking and manufacturing, custom stainless steel casting stands out as a vital process that combines artistry with engineering precision. Whether for industrial applications, architectural features, or intricate artistic designs, the capabilities offered by stainless steel casting foundries have become a cornerstone of modern manufacturing. This article delves into the intricacies of stainless steel casting, highlighting its advantages, processes, and the various applications it serves.

Understanding Custom Stainless Steel Casting

Custom stainless steel casting refers to the process of creating metal components tailored to specific designs and specifications. It involves pouring molten stainless steel into a mold, which shapes the metal as it cools and solidifies. This method offers significant flexibility, allowing for complex geometries and customized designs that would be challenging or impossible to achieve through traditional machining methods.

The Advantages of Stainless Steel

Stainless steel is a preferred choice for many applications due to its inherent properties. Its excellent resistance to corrosion makes it ideal for challenging environments, while its strength and durability ensure longevity. Furthermore, stainless steel offers aesthetic appeal with its shiny, modern finish, making it suitable for both functional and decorative applications. When combined with custom casting techniques, these properties enhance the material's versatility, expanding its use in various industries.

The Casting Process

The casting process for stainless steel typically involves several key stages

1. Pattern Creation The first step in the casting process is the creation of a pattern, which is a replica of the desired final product. Patterns are usually made from materials such as wax, plastic, or metal and can be single-use or reusable.

custom stainless steel casting foundry

2. Mold Making Once the pattern is complete, a mold is created around it. This can be achieved through various methods, including sand casting, investment casting, and shell molding. Each method has its own benefits, with investment casting offering superior surface finish and dimensional accuracy.

3. Melting and Pouring The next step involves melting stainless steel in a furnace and pouring it into the mold. The temperature and purity of the molten metal are meticulously controlled to ensure the highest quality and consistency.

4. Cooling and Solidification After the molten metal is poured into the mold, it is allowed to cool and solidify. This stage is critical as it determines the final properties of the cast component.

5. Finishing Touches Once the stainless steel has cooled, the mold is removed, and the casting undergoes a series of finishing processes such as machining, polishing, or surface treatment. These steps enhance the final product's aesthetics and functionality.

Applications of Custom Stainless Steel Casting

The applications of custom stainless steel casting are vast and varied. Industries such as aerospace, automotive, healthcare, and architecture frequently rely on these cast components. For instance, in the aerospace sector, weight-saving yet robust components are crucial for performance and safety. Custom stainless steel castings can provide the ideal balance of strength and weight.

In architectural design, custom stainless steel elements contribute to modern aesthetics while offering durability. From railings and fixtures to complex sculptures, the possibilities are nearly limitless. Moreover, the healthcare industry utilizes custom castings for surgical instruments and medical devices, where precision and sterility are paramount.

Conclusion

Custom stainless steel casting is more than a manufacturing process; it is a synthesis of art and technology that enables the creation of unique, high-quality components tailored to specific needs. With its myriad advantages, including corrosion resistance, durability, and aesthetic appeal, stainless steel continues to be a material of choice across various sectors. As technology in foundry practices evolves, the potential for innovative applications will only expand, making custom stainless steel casting an integral part of the modern manufacturing landscape. Whether you require components for industrial machinery or artistic creations, a custom stainless steel casting foundry can turn your vision into reality, embodying both functionality and artistry.

-

Durable Cast Iron Water Main Pipe | AI-Optimized Design

NewsAug.05,2025

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025