снеж . 11, 2024 21:15 Back to list

heat exchanger purchase

The Importance of Purchasing Heat Exchangers in Industrial Applications

Heat exchangers are critical components in a wide array of industrial processes, playing an essential role in improving energy efficiency, optimizing thermal performance, and facilitating safe and effective heat transfer between fluids. The decision to purchase a heat exchanger is not one that should be taken lightly, as it can have significant implications for operational efficiency, cost management, and environmental compliance. In this article, we explore the key factors to consider when purchasing heat exchangers and their benefits to industrial applications.

Understanding Heat Exchangers

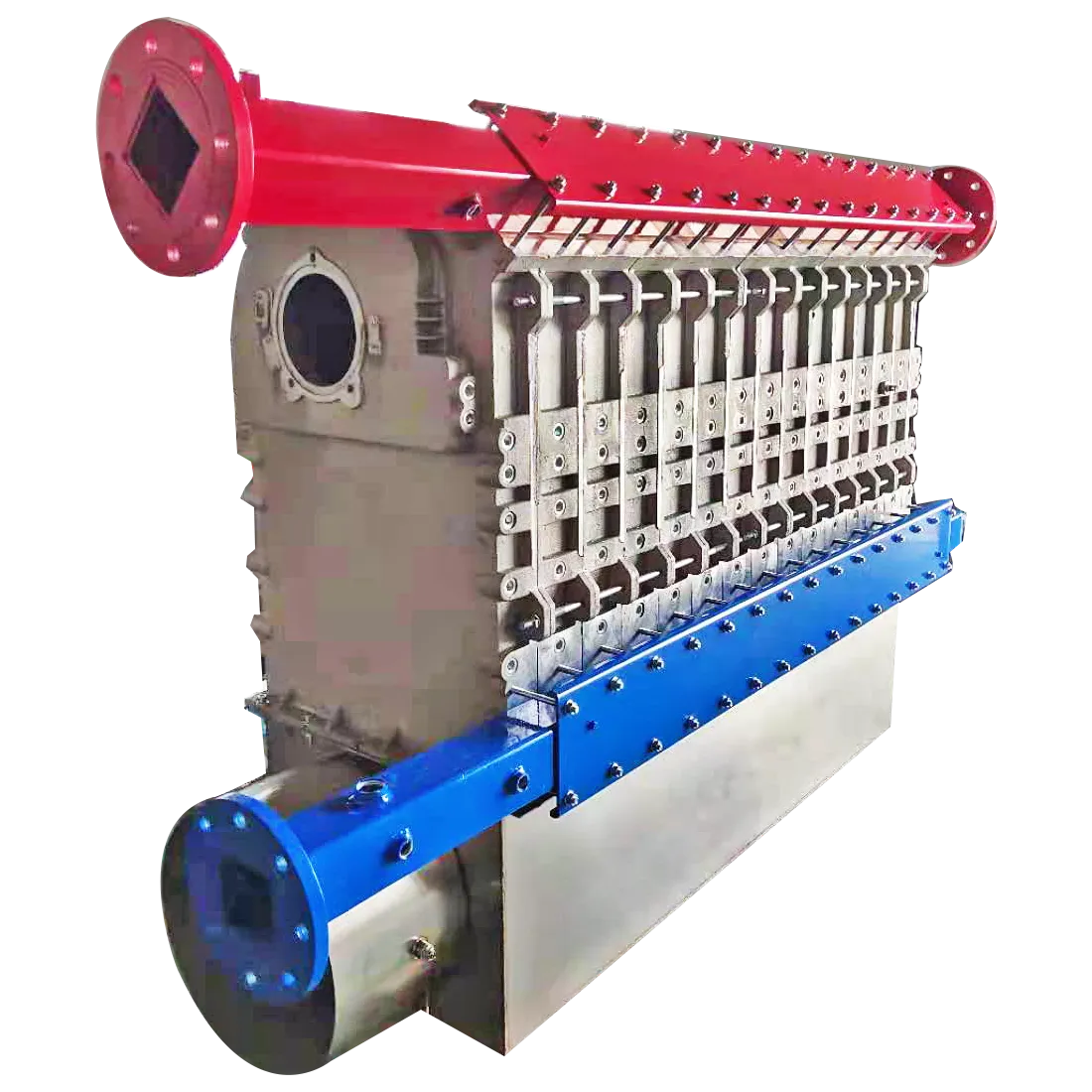

At its core, a heat exchanger is a device that allows heat to flow from one medium to another with minimal mixing. Whether in heating, cooling, condensing, or boiling applications, heat exchangers are prevalent across various industries, including chemical processing, oil and gas, food and beverage, power generation, and HVAC systems. Types of heat exchangers include shell and tube, plate, air-cooled, and spiral configurations, each serving specific functions and suited for various applications.

Key Considerations When Purchasing Heat Exchangers

1. Application Requirements Before purchasing a heat exchanger, it is crucial to assess the specific requirements of your application. This includes understanding the operating temperature and pressure, the types of fluids involved, and the desired heat transfer efficiency. Different applications may require distinct types of heat exchangers optimized for particular conditions.

2. Material Selection The choice of materials is vital in the selection of heat exchangers. Factors such as corrosion resistance, thermal conductivity, and compatibility with process fluids must be considered. Common materials include stainless steel, copper, and various alloys; each material offers different benefits and drawbacks depending on the service conditions.

3. Size and Capacity The size of the heat exchanger will directly affect its performance and efficiency. It is essential to conduct a thorough thermal analysis to determine the appropriate size and capacity that meet your heat transfer requirements. Undersized units can lead to inadequate performance, while oversized units may unnecessarily inflate costs and occupy space.

4. Efficiency and Performance Energy efficiency is a primary concern for many industries today. When evaluating heat exchangers, consider their thermal efficiency and how they contribute to energy savings. High-performance models may come with advanced features such as enhanced surface area or finning, which improve heat transfer without significant size increases.

5. Regulatory Compliance Depending on your industry, various regulatory standards must be met when purchasing heat exchangers, particularly in food processing or hazardous materials handling environments. Ensure that the equipment complies with relevant codes and standards, which can vary by region and industry.

heat exchanger purchase

6. Cost and Budget While it may be tempting to opt for the cheapest option, it's essential to evaluate the total cost of ownership rather than just the upfront purchase price. Consider aspects such as maintenance, energy consumption, and expected lifespan when calculating costs to ensure you are making a financially sound investment.

7. Supplier Reputation and Support Selecting a reputable supplier is crucial for ensuring quality and reliability in your heat exchanger purchase. Look for manufacturers with a proven track record, strong warranties, and good customer support. After-sales service is also essential for maintenance and troubleshooting.

Benefits of Investing in Quality Heat Exchangers

Investing in a quality heat exchanger can bring numerous benefits to an industrial operation, including

- Enhanced Energy Efficiency By improving heat transfer efficiency, high-quality heat exchangers reduce energy consumption and operational costs.

- Increased Productivity With reliable performance and reduced downtime, heat exchangers contribute to smoother operational workflows and increased productivity.

- Improved Product Quality Consistent temperature control facilitated by efficient heat exchangers can lead to better product quality, especially in sensitive manufacturing processes.

- Regulatory Compliance Reliable heat exchangers help ensure compliance with environmental regulations, reducing risks associated with process failures and associated penalties.

Conclusion

Purchasing a heat exchanger is a crucial investment in any industrial setting, directly affecting efficiency, cost, and compliance. By carefully considering the factors outlined above, organizations can make informed decisions that result in optimal heat exchange solutions tailored to their specific needs. Ultimately, the right heat exchanger can enhance overall productivity, environmental performance, and profitability, making it a fundamental component of successful industrial operations.

-

Premium Cast Iron Water Main Pipe for Robust Infrastructure

NewsAug.27,2025

-

A-Rated Cast Aluminum Boilers: High-Efficiency Condensing Gas & LPG

NewsAug.26,2025

-

OEM Cast Silicon Aluminum Alloy Heat Exchanger | Custom & High Performance

NewsAug.25,2025

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025