- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

окт. . 06, 2024 11:29 Back to list

china punching concrete pipe mold pallet

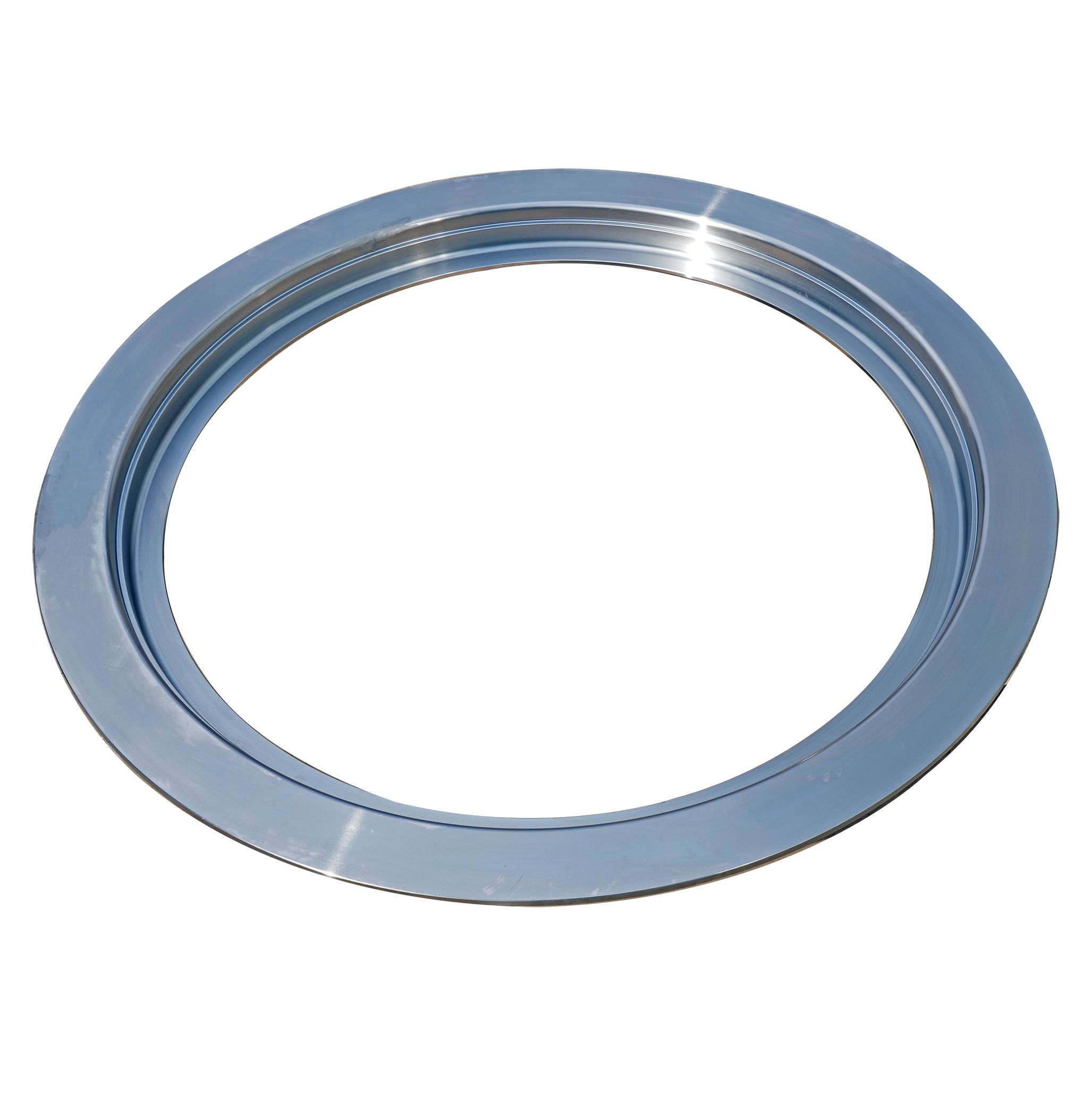

The Future of Construction China’s Punching Concrete Pipe Mold Pallet

In the ever-evolving world of construction, innovation is at the forefront of shaping how we build infrastructure. One such innovation that is gaining traction globally is the use of punching concrete pipe mold pallets. These advancements, particularly coming out of China, are redefining efficiency and quality in the manufacture of concrete pipes, a crucial component in modern civil engineering.

Understanding Punching Concrete Pipe Mold Pallets

Punching concrete pipe mold pallets are specially designed frameworks used in the production of concrete pipes. These molds are engineered to withstand the pressure and stress of the concrete during the curing process, ensuring that the final products are robust and durable. The punching aspect refers to the technique that enhances the molding process, allowing for more precise and intricate designs. This is particularly important as infrastructure demands evolve, often necessitating pipes that can fit specific requirements or perform under unique conditions.

Benefits of Using Punching Concrete Pipe Mold Pallets

1. Enhanced Durability The primary advantage of using high-quality molds is the increased strength and longevity of the concrete pipes produced. The use of advanced materials and innovative designs means these molds can produce pipes capable of withstanding high pressure and harsh environmental conditions.

2. Cost Efficiency By streamlining the manufacturing process, these pallets reduce the overall production costs associated with concrete pipe manufacturing. The efficiency gained from using advanced molds leads to less waste and an optimized use of materials, which translates to significant savings for manufacturers.

3. Precision Engineering With the application of punching technology, manufacturers can create concrete pipes that meet exact specifications. This level of precision is essential in projects where dimensions are critical to the overall integrity of the infrastructure.

4. Flexibility in Design Punching molds allow for greater versatility in the design of concrete pipes. This becomes increasingly important as modernization and customization of infrastructure components are demanded by clients in various sectors.

china punching concrete pipe mold pallet

5. Sustainability The reduction in waste and improved efficiency in production contribute to more sustainable manufacturing processes. Moreover, the durability of the pipes leads to less frequent replacements, contributing to a more sustainable approach to construction.

China’s Role in Development

China has emerged as a leader in the development and production of punching concrete pipe mold pallets. The country's strong emphasis on infrastructure development, coupled with its manufacturing capabilities, has created an environment where innovations can flourish. Chinese manufacturers are continually refining their processes, striving to develop molds that incorporate the latest technologies and materials science knowledge.

These advancements not only benefit the Chinese market but also have a global reach. Many countries are looking towards China for high-quality concrete pipe molds, recognizing their reputation for producing reliable and effective construction materials.

Challenges and Considerations

Despite the innovations, challenges remain in the adoption of these technologies. The initial investment for high-quality punching concrete pipe mold pallets can be significant. However, the long-term benefits—reduced costs and enhanced product quality—often outweigh these initial hurdles.

Additionally, as with any technological advancement, training and expertise are required to fully leverage the advantages of these molds. Companies need to ensure their teams are well-equipped to handle the new systems and processes.

Conclusion

As the construction industry seeks innovative solutions to meet the demands of modern infrastructure, China's advancements in punching concrete pipe mold pallets stand out as a beacon of progress. The benefits offered by these molds—including enhanced durability, cost efficiency, and flexibility—are enhancing the quality of concrete piping, which is crucial for various applications. As more companies embrace these technologies, we can anticipate a significant transformation in the construction landscape, paving the way for smarter, more sustainable industrial practices. The future of construction continues to look bright, and innovations like these are at the heart of it.

-

High-Precision Colloidal Silica Casting Solutions Custom & ODM

NewsMay.20,2025

-

High-Efficiency Cast Silico Aluminum Gas Boiler ODM & Custom Solutions

NewsMay.20,2025

-

Steel Reinforced Concrete Pipe Bottom Ring Moulds Buy Custom Solutions

NewsMay.19,2025

-

Original Concrete Pipe Mold Bottom Ring & Pallet Chinese Factory Direct Sale

NewsMay.19,2025

-

Custom Room Heating Heat Exchangers Energy-Efficient Solutions

NewsMay.18,2025

-

Precision Milling Body Casting Solutions Custom & ODM Options

NewsMay.18,2025