- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

নভে. . 04, 2024 15:35 Back to list

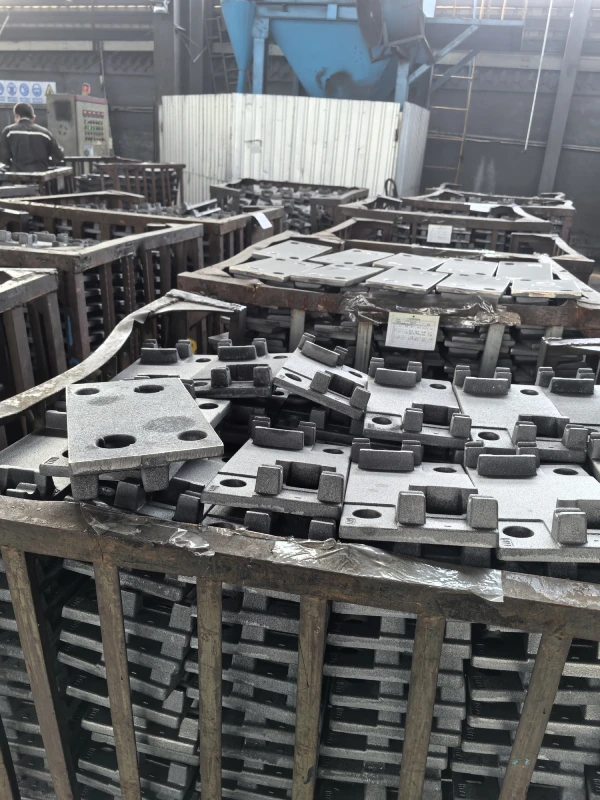

OEM Cast Silicon Aluminum Alloy Gas Boiler for Efficient Heat Generation

The Benefits of OEM Cast Silicon Aluminum Alloy Gas Fired Boilers

In recent years, the industrial landscape has experienced a significant shift towards efficiency and sustainability. This transition has brought forth an array of innovative technologies, among which the OEM cast silicon aluminum alloy gas fired boiler stands out. These boilers, designed for optimal performance, combine durability, efficiency, and environmental responsibility, making them a preferred choice for various industrial applications.

Understanding OEM Cast Silicon Aluminum Alloy

Original Equipment Manufacturer (OEM) components are designed and manufactured specifically for machines or systems by authorized manufacturers. Cast silicon aluminum alloys are critical in this context due to their excellent mechanical properties. The incorporation of silicon in aluminum enhances the alloy's resilience and stability, making it ideal for high-temperature applications such as boilers. The overall benefits of using these alloys include improved resistance to corrosion and oxidation, which are crucial for systems that operate under harsh conditions.

How Gas Fired Boilers Operate

Gas fired boilers utilize gas as a primary fuel source to produce steam or hot water for heating applications. The combustion process involves burning natural gas or propane to generate heat, which is then transferred to water or steam. This method of heating is recognized for its efficiency and lower emissions compared to other fuel sources, such as coal or oil. By harnessing gas as fuel, industries can achieve significant energy savings while adhering to stringent environmental regulations.

Efficiency Gains

One of the key advantages of OEM cast silicon aluminum alloy gas fired boilers is their high thermal efficiency. These boilers are designed with advanced technology to maximize heat transfer, minimizing energy losses. Enhanced efficiency not only reduces operational costs but also contributes to a smaller carbon footprint. This is particularly important for industries striving to meet environmental standards and sustainability goals.

Durability and Maintenance

Durability is another significant aspect of OEM cast silicon aluminum alloy gas fired boilers. The unique properties of silicon aluminum alloys provide high resistance to thermal stress and degradation over time. This means that these boilers can withstand extreme temperatures and pressures, ensuring reliable operation over their lifespan. Additionally, they often require less maintenance compared to conventional materials, further reducing downtime and operational costs for industries.

oem cast silicon aluminum alloy gas fired boiler

Regular maintenance is essential for any boiler system, but the robust nature of cast silicon aluminum alloy boilers means that they need less frequent repairs. This reliability allows industries to focus on production rather than worrying about equipment failure or extensive maintenance schedules.

Environmental Considerations

As the world moves towards a greener future, the demand for eco-friendly technologies has never been higher. OEM cast silicon aluminum alloy gas fired boilers align with this movement by offering a cleaner alternative to traditional heating systems. With lower carbon emissions and pollutants, these boilers help industries comply with environmental regulations, contributing to better air quality and reduced ecological impact.

Furthermore, the efficiency gains from these boilers mean that less fuel is consumed for the same amount of heat, leading to lower greenhouse gas emissions. This dual benefit makes them an attractive option for companies aiming to enhance their sustainability initiatives.

Versatility in Applications

Another notable advantage of these boilers is their versatility. They are suitable for various applications across industries, including manufacturing, food processing, chemical production, and more. Their ability to provide consistent and reliable heat makes them indispensable in processes that require precise temperature control.

Moreover, the adaptability of cast silicon aluminum alloys allows OEM manufacturers to customize boiler designs for specific needs, ensuring that businesses can get the most suitable solutions for their operations.

Conclusion

In conclusion, OEM cast silicon aluminum alloy gas fired boilers represent a significant advancement in boiler technology. Their combination of efficiency, durability, low environmental impact, and versatility makes them an ideal choice for a wide range of industrial applications. As industries continue to seek innovative solutions to meet both economic and environmental challenges, these boilers stand out as a reliable and forward-thinking option. Investing in such technology not only enhances operational performance but also supports a greener future, ensuring that businesses are well-positioned for continued success in an ever-evolving marketplace.

-

Custom Low-NOx Gas Boilers Efficient Commercial Heating Solutions

NewsMay.25,2025

-

Low-NOx Condensing Gas-Fired Boilers Efficient & Custom Solutions

NewsMay.25,2025

-

Custom Domestic Hot Water Heat Exchangers Efficient & Durable

NewsMay.24,2025

-

Cast Iron vs. Ductile Iron Differences, Uses & Benefits

NewsMay.24,2025

-

Top Gas Fired Boiler Supplier High-Efficiency Solutions & OEM Support

NewsMay.23,2025

-

Marine Gear Box Casting Solutions Durable & Custom OEM/ODM

NewsMay.23,2025