- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

nov . 20, 2024 15:49 Back to list

gray iron cast

Understanding Gray Iron Castings

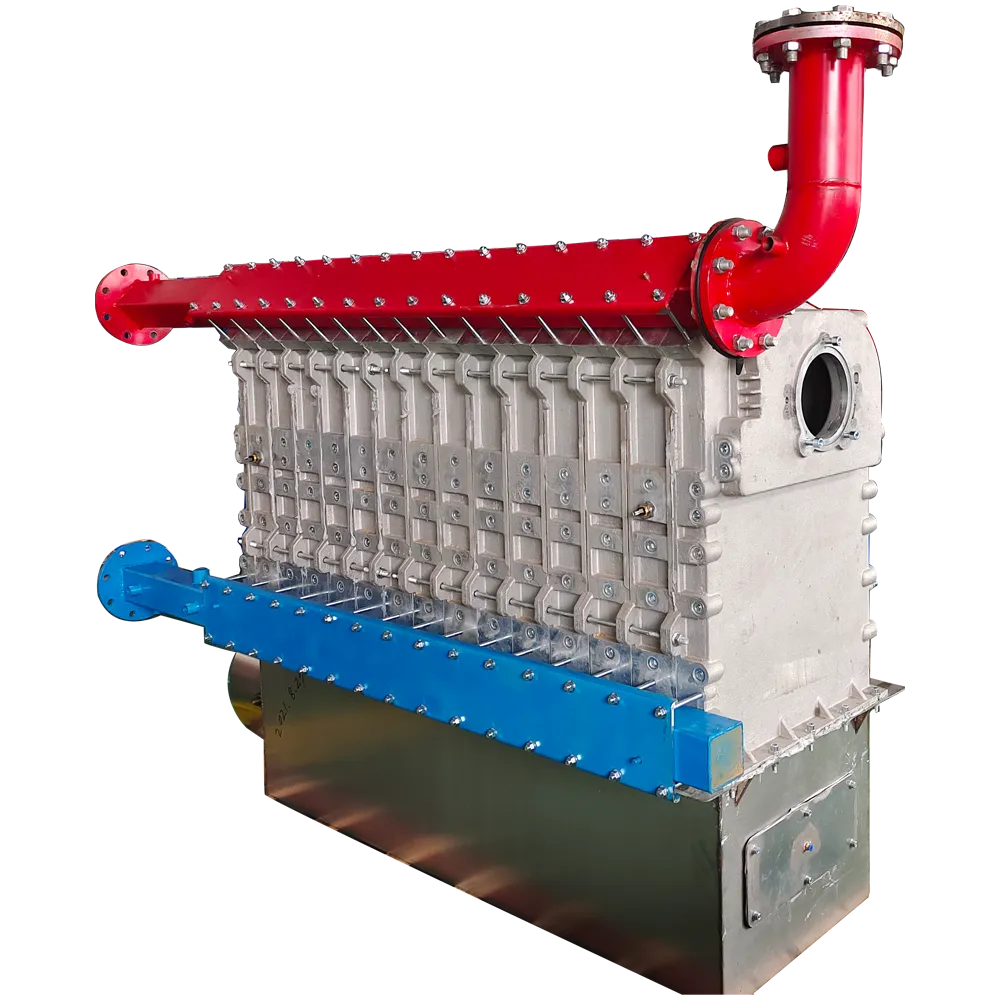

Gray iron castings are a foundational element in modern manufacturing, known for their unique properties and versatility. This material is one of the most widely used types of cast iron, primarily due to its excellent castability, good machinability, and remarkable wear resistance. Characterized by its gray color, which comes from the presence of graphite flakes in its microstructure, gray iron is commonly employed in various applications ranging from automotive components to industrial machinery.

One of the significant advantages of gray iron is its ability to absorb vibrations, making it an ideal choice for applications requiring sound dampening. This property is especially beneficial in engine blocks and machine tool structures, where vibration management is critical for performance and longevity. Due to its high thermal conductivity, gray iron also excels in heat dissipation, which is essential for components like cylinder heads and exhaust manifolds.

The manufacturing process of gray iron typically involves melting iron and alloying it with carbon and silicon. The carbon forms into graphite flakes as the molten iron cools and solidifies, giving gray iron its distinctive appearance and properties. The proportion of silicon, carbon, and other alloying elements can be adjusted to achieve different mechanical properties, enabling engineers to tailor the material to specific needs. This adaptability makes gray iron castings a preferred choice in various industries, including automotive, aerospace, and construction.

gray iron cast

In terms of mechanical properties, gray iron exhibits excellent compressive strength and good tensile strength. However, it is relatively brittle compared to other metals, which can limit its use in applications where impact resistance is paramount. Nevertheless, the trade-off in brittleness is often worth it for the benefits that gray iron provides in terms of durability and resistance to wear. In fact, many manufacturers opt for gray iron castings over alternatives due to their cost-effectiveness and reliable performance.

Sustainability is another important aspect of gray iron production. The recycling of scrap iron and castings is a common practice, significantly reducing waste and energy consumption in the manufacturing process. As industries increasingly focus on environmental responsibility, the use of recyclable materials like gray iron is expected to rise.

In conclusion, gray iron castings are an integral component in a wide range of applications due to their unique properties, manufacturability, and sustainability. As technology evolves, so too will the methods of casting and application of gray iron, ensuring it remains a vital resource for future manufacturing innovations.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025