febr. . 15, 2025 00:17 Back to list

heat exchangers materials

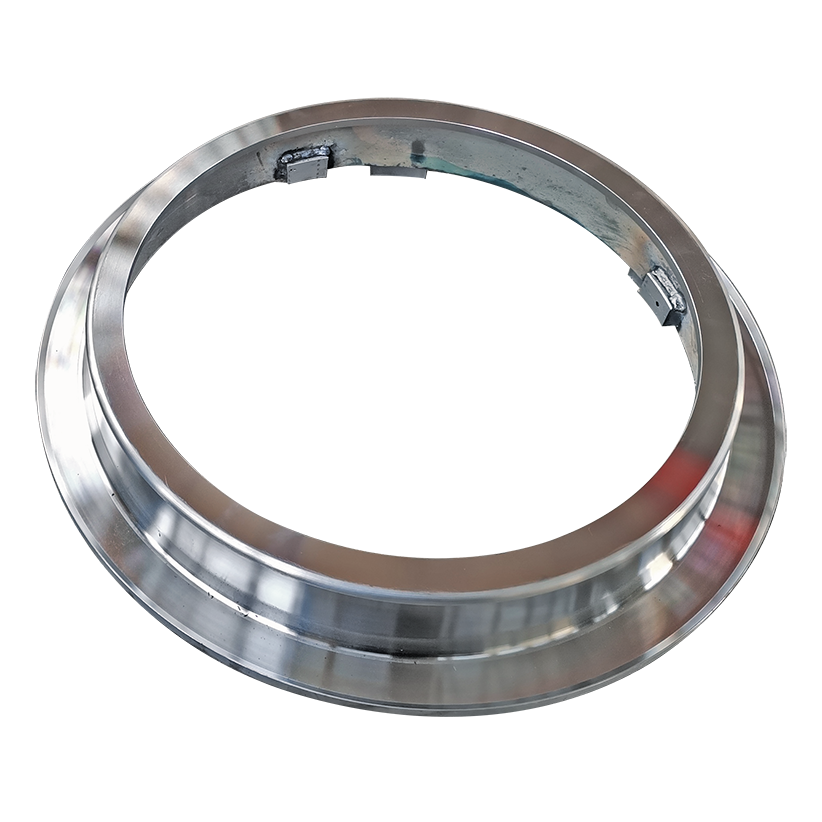

Exploring the right materials for heat exchangers is crucial to their efficiency and longevity. As systems crucial for transferring heat between fluids, choosing durable and effective materials can greatly influence their performance and lifespan.

In extreme conditions, nickel alloys emerge as an optimal solution. Renowned for withstanding high temperatures and aggressive environments, these materials are used in energy sectors, such as nuclear power, where conditions demand the ultimate in material performance. As the technology progresses, composite materials are entering the scene, often providing customized solutions for specific challenges faced by traditional materials. These advanced materials can be tailored to combine strengths from various elements, creating a unique offering for industries aiming to push the boundaries of heat exchanger performance. When evaluating materials for heat exchangers, gather insights from field data and expert reviews. Consult with specialists familiar with the specific thermal and mechanical stresses of your applications is invaluable. This practice ensures that the selected materials not only meet thermal and durability needs but also align with budgetary constraints and regulatory requirements. Understanding the life cycle of these materials and any potential need for replacement parts can enhance operational planning and cost forecasting. Material choice directly correlates with the efficiency of heat exchangers. Optimize their function to maximize energy savings and operational efficiency. Correct material selection reduces energy consumption, extends equipment life, and improves overall system reliability. In conclusion, material selection for heat exchangers is a critical decision that significantly influences system performance and longevity. By embracing advanced materials and working closely with experts, industries can ensure their heat exchangers perform efficiently, withstand harsh environments, and offer a cost-effective solution tailored to their needs. Prioritizing the right materials not only boosts performance but also secures a competitive edge through improved reliability and sustainability.

In extreme conditions, nickel alloys emerge as an optimal solution. Renowned for withstanding high temperatures and aggressive environments, these materials are used in energy sectors, such as nuclear power, where conditions demand the ultimate in material performance. As the technology progresses, composite materials are entering the scene, often providing customized solutions for specific challenges faced by traditional materials. These advanced materials can be tailored to combine strengths from various elements, creating a unique offering for industries aiming to push the boundaries of heat exchanger performance. When evaluating materials for heat exchangers, gather insights from field data and expert reviews. Consult with specialists familiar with the specific thermal and mechanical stresses of your applications is invaluable. This practice ensures that the selected materials not only meet thermal and durability needs but also align with budgetary constraints and regulatory requirements. Understanding the life cycle of these materials and any potential need for replacement parts can enhance operational planning and cost forecasting. Material choice directly correlates with the efficiency of heat exchangers. Optimize their function to maximize energy savings and operational efficiency. Correct material selection reduces energy consumption, extends equipment life, and improves overall system reliability. In conclusion, material selection for heat exchangers is a critical decision that significantly influences system performance and longevity. By embracing advanced materials and working closely with experts, industries can ensure their heat exchangers perform efficiently, withstand harsh environments, and offer a cost-effective solution tailored to their needs. Prioritizing the right materials not only boosts performance but also secures a competitive edge through improved reliability and sustainability.

Share

Pervious:

Next:

Latest news

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025