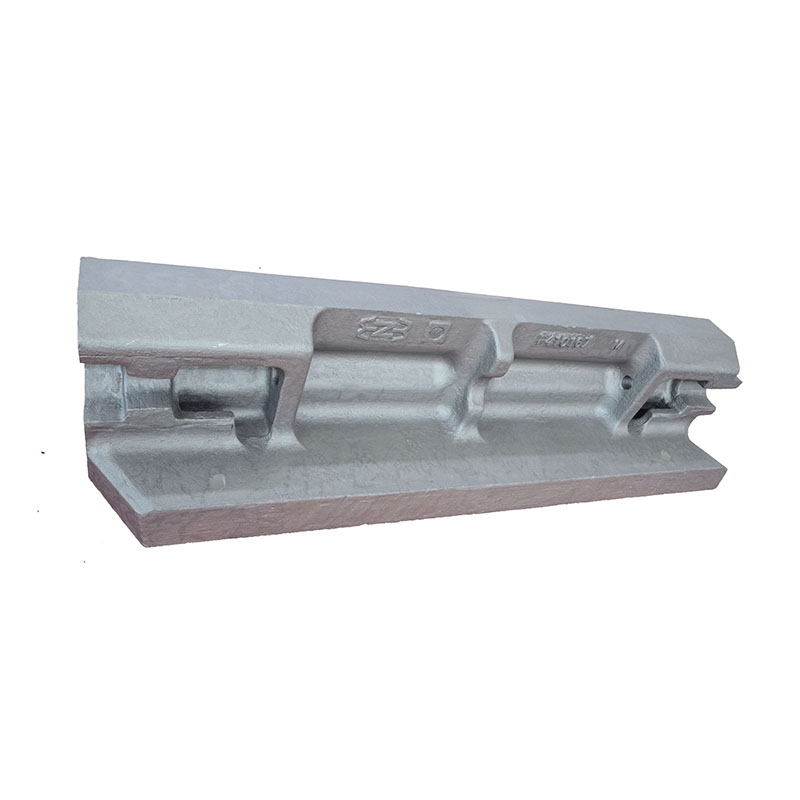

insertion board

|

material |

ZG30MnSi |

|

usage |

coal conveying equipment for coal mines |

|

|

casting technology |

VRH Sodium Silicate Sand and Ester Hardened Sodium Silicate Sand Casting |

|

|

unit weight |

800kgs |

|

|

productivity |

20000 tons/year |

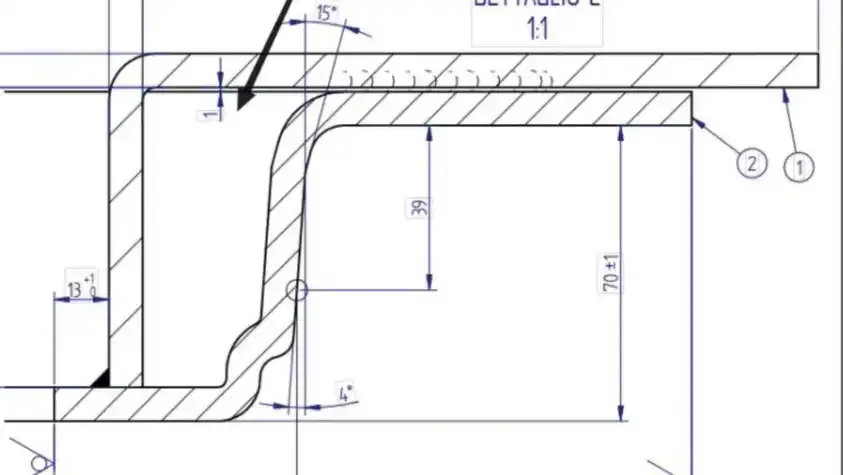

dam-board

|

material |

ZG30MnSi |

|

usage |

coal conveying equipment for coal mines |

|

|

casting technology |

VRH Sodium Silicate Sand and Ester Hardened Sodium Silicate Sand Casting |

|

|

unit weight |

700kg |

|

|

productivity |

20000 tons/year |

Product Description

Sand casting is a traditional casting method, normally used to make large parts (typically Iron and Steel but also Bronze, Brass, Aluminum). Molten metal is poured into a mold cavity formed out of sand, after the molten metal cooled and then the products comes out.

Carbon steel is an extremely popular material option for steel castings, as it has a vast range of applications in several different industries. For the low material cost and a variety of material grades, carbon steel casting is commonly used and can improve its strength, ductility and other performance by heat treatment for industrial applications. Carbon steel is safe and durable and has a high level of structural integrity, features that add to its popularity and make it one of the most created alloys in the world.

We are very good at large scale steel castings. Our normal casting process as follows:

Mould and molding:

|

|

Pouring and Casting:

|

|

Grinding, Cutting and Annealing

|

|