- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Dis . 02, 2024 07:07 Back to list

foundry steel casting

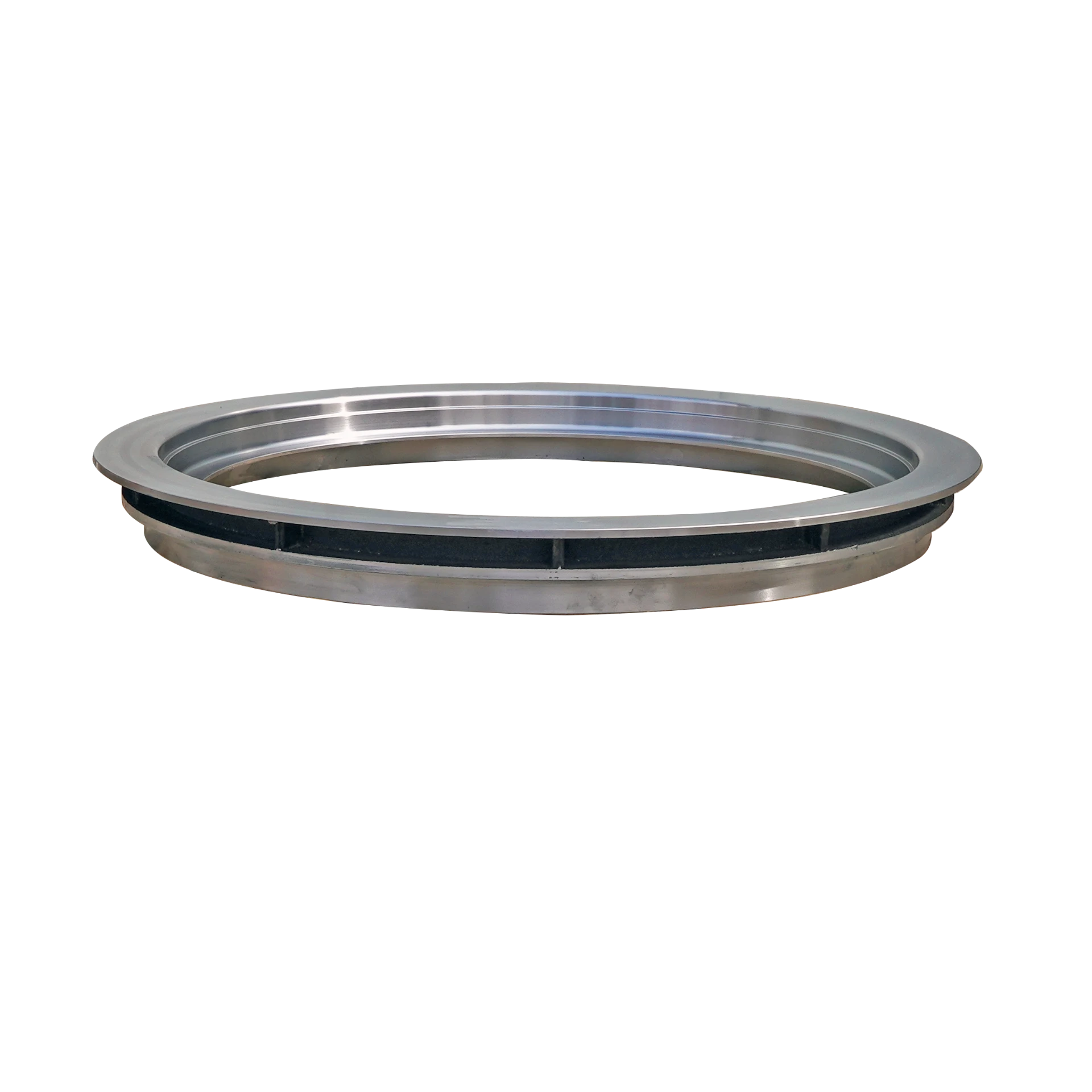

Exploring the World of Foundry Steel Casting

Foundry steel casting is a vital process in the manufacturing industry, playing a crucial role in creating intricate and durable components used in various applications. This process involves pouring molten metal into a mold to create a specific shape and size, making it an essential technique for producing components that require high strength and precision.

The Casting Process

The steel casting process begins with the selection of raw materials. The most common materials used in steel casting include carbon steel, alloy steel, and stainless steel. Depending on the application requirements, different grades of steel can be utilized to achieve the desired properties, such as corrosion resistance, tensile strength, and ductility.

The next step involves creating a mold that will define the shape of the final product. Molds can be made from various materials, including sand, metal, or ceramic, depending on the complexity of the design and the required surface finish. In foundry practices, sand casting is one of the most prevalent techniques due to its versatility and cost-effectiveness.

Once the mold is prepared, the molten steel is poured into it. This requires careful control of temperature and timing to ensure that the steel flows uniformly into the mold and fills every cavity. The cooling process is equally important, as it affects the mechanical properties of the final casting. The cooling rate can be controlled to minimize defects such as cracks or warping.

Advantages of Steel Casting

One of the primary advantages of steel casting is its ability to produce complex shapes that would be difficult or impossible to achieve using other manufacturing processes. This versatility makes it suitable for a wide range of applications, including automotive, aerospace, construction, and machinery parts.

Another significant benefit is the durability of cast steel components. Steel castings can withstand high levels of stress and adverse environmental conditions, making them ideal for critical applications. Additionally, they can be engineered to meet specific requirements, allowing for customized solutions that suit individual needs.

foundry steel casting

Applications of Foundry Steel Casting

Foundry steel casting is used in a variety of industries. In the automotive sector, for instance, it is utilized to manufacture engine blocks, transmission cases, and various structural components that require high strength and durability. In the aerospace industry, steel castings are used for critical components in aircraft engines and structural parts due to their exceptional mechanical properties.

Moreover, the construction industry benefits from steel casting in the production of heavy machinery components, supporting structures, and even decorative architectural elements. The versatility and strength of cast steel make it an ideal choice for demanding applications across many sectors.

Challenges in Steel Casting

Despite its advantages, foundry steel casting is not without challenges. The process requires significant expertise and precision, as even minor errors in temperature control or mold preparation can lead to defects. Moreover, the environmental impact of foundries, such as emissions and waste generation, has prompted the industry to adopt more sustainable practices.

Advancements in technology, such as computer-aided design (CAD) and 3D printing, are helping to mitigate some of these challenges. These technologies allow for better mold designs and more efficient production processes, leading to improved quality and reduced waste.

Conclusion

Foundry steel casting is a cornerstone of modern manufacturing, providing durable and complex parts that meet the needs of various industries. As technology continues to evolve, the efficiency and sustainability of the steel casting process will likely improve, ensuring that this essential method remains relevant in the future. Understanding its intricacies and applications gives us a glimpse into the profound impact of steel casting on the world around us.

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025

-

Durable Cast Iron Water Main Pipe | Buy Ductile Pipe

NewsAug.06,2025