- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 21, 2024 20:08 Back to list

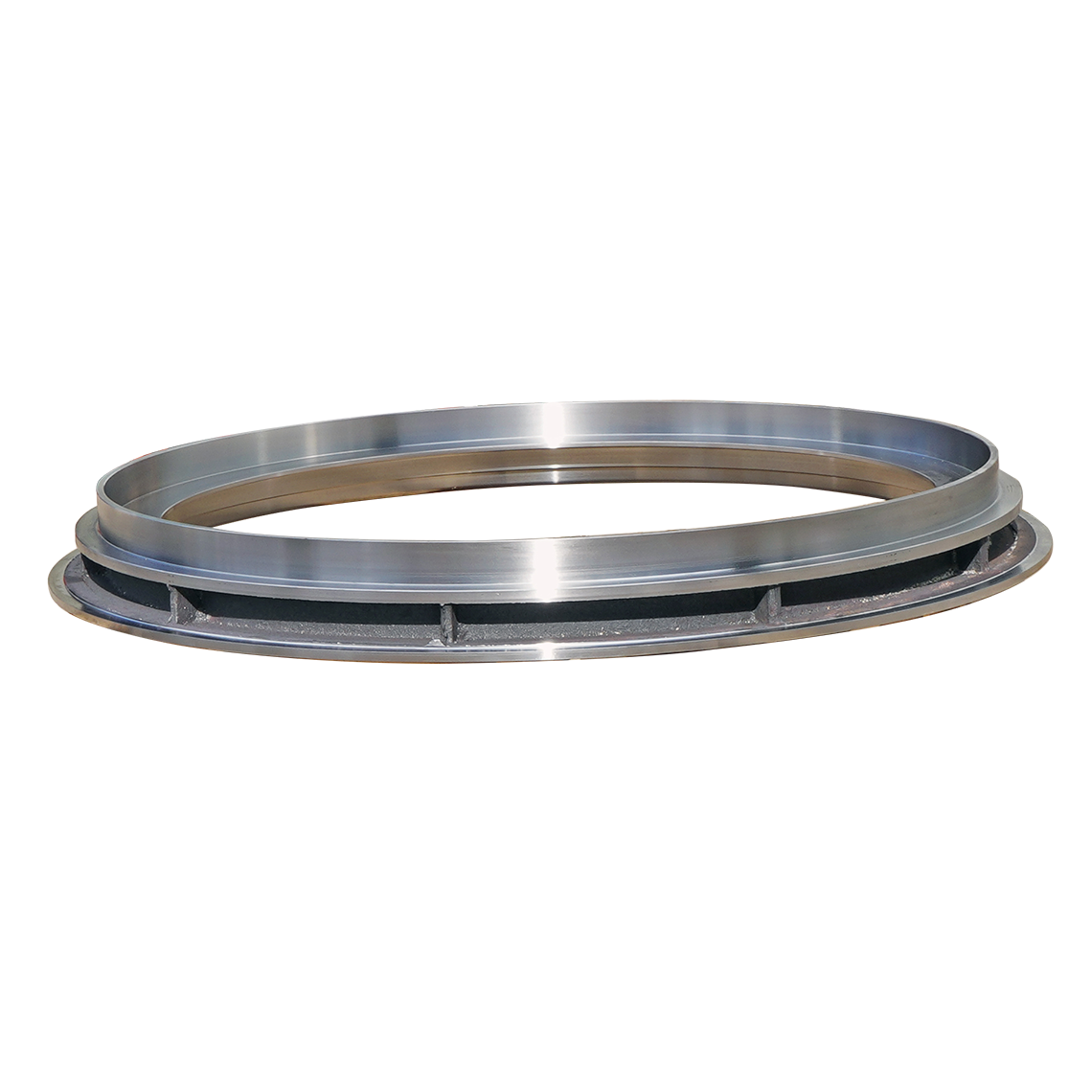

ductile iron pipe mold pallet

The Importance of Ductile Iron Pipe Mold Pallets in Modern Infrastructure

Ductile iron pipes are an essential component in the transportation of water and wastewater, playing a critical role in municipal infrastructure. The process of manufacturing these pipes requires precision and efficiency, closely tied to the use of mold pallets. This article explores the significance of ductile iron pipe mold pallets in the production process, their advantages, and their impact on the overall quality of ductile iron pipes.

What are Mold Pallets?

Mold pallets are flat platforms that serve as the base for the molds used in the production of ductile iron pipes. These pallets must be designed to withstand the high temperatures and pressures involved in the casting process. Typically made from durable materials, they are engineered to provide stability, ensuring that the molds maintain their shape and dimensions during the casting and cooling processes.

Efficiency in Production

One of the primary advantages of using mold pallets in the production of ductile iron pipes is the increased efficiency they provide. By utilizing mold pallets, manufacturers can streamline their production lines, leading to faster cycle times and reduced labor costs. The pallets allow for easier handling and transportation of molds, which minimizes the risk of damage and facilitates quicker transitions between different production phases.

Moreover, mold pallets can be designed with features such as interlocking systems or ergonomic handles that improve the workflow in manufacturing facilities. These enhancements can drastically reduce turnaround times, allowing companies to meet high demand without compromising quality.

Quality Assurance

Quality control is paramount in the production of ductile iron pipes. Using mold pallets contributes significantly to ensuring the final product meets the required standards. The rigid structure of the pallets helps maintain the dimensional integrity of the molds throughout the casting process, resulting in pipes that meet strict specifications for strength and durability.

ductile iron pipe mold pallet

Inconsistent mold shapes can lead to defects, which not only jeopardize the integrity of the pipes but can also lead to costly rework and delays

. By ensuring molds are correctly aligned and stabilized, mold pallets help to prevent such issues, thereby enhancing the overall quality of the finished products.Customization and Versatility

Another notable advantage of mold pallets is their versatility. Manufacturers can customize mold pallets to accommodate different pipe sizes and specifications. This adaptability allows for more efficient production runs tailored to specific project requirements. Additionally, the ability to modify mold pallets means manufacturers can easily transition from one project to another, reducing downtime and maximizing productivity.

The versatility of mold pallets also extends to their compatibility with various molding techniques. Whether a manufacturer employs sand casting, investment casting, or other methods of ductile iron pipe production, mold pallets can be designed to fit seamlessly into their existing processes.

Environmental Considerations

In today’s manufacturing landscape, there is a growing emphasis on sustainability. Mold pallets play a role in reducing waste within the production cycle. By providing a consistent and durable base for molds, they contribute to minimizing defective products which, in turn, reduces the material required for repairs and replacements. Furthermore, advancements in mold pallet technology are leading to the use of more environmentally friendly materials, aligning with the industry's push towards sustainability.

Conclusion

In conclusion, ductile iron pipe mold pallets are an integral part of the manufacturing process for ductile iron pipes. They enhance efficiency, ensure quality, and offer customization options that cater to a wide range of production needs. As the demand for robust and reliable infrastructure continues to grow, the role of mold pallets will remain crucial in supporting manufacturers to meet these challenges, helping to lay the groundwork for a sustainable and efficient future in municipal water management. As technology advances, so too will the capabilities and applications of mold pallets, making them an indispensable tool in the industry.

-

Low NOx Condensing Gas Boilers for Commercial Heating High Efficiency

NewsMay.29,2025

-

Custom & ODM Cast Steel Pipe Mould Bottom Ring Suppliers

NewsMay.29,2025

-

Custom Ductile Iron Pipe Mold Pallets High Durability & Order Now

NewsMay.29,2025

-

Custom Punch Concrete Pipe Mold Pallets Durable & Precision-Made

NewsMay.29,2025

-

Custom Punch Concrete Pipe Mould Pallets Durable & Precision-Engineered

NewsMay.29,2025

-

EN877 Epoxy Coating for Gray Cast Iron Fittings Buy, Custom & ODM

NewsMay.29,2025