- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Led . 14, 2025 15:51 Back to list

Cast Aluminum-Silicon Alloy Radiator/ Exchanger for Natural Gas Fired Boiler

Manhole cover ductile iron casting has undergone significant evolution over the years, emerging as an indispensable component in urban infrastructure. This article delves into the facets of its manufacturing process, inherent advantages, and why it remains a preferred choice in modern urban settings, underlining the principles of experience, expertise, authoritativeness, and trustworthiness.

Advantages of ductile iron castings over their conventional counterparts are manifold. High tensile strength and flexibility mean that ductile iron covers face less likelihood of fracturing under pressure, which enhances safety and longevity. Additionally, the material's ability to absorb vibrations reduces noise pollution—a critical feature for densely populated areas. These functional benefits underscore the trustworthiness of ductile iron as a material of choice, offering peace of mind to urban planners and end-users alike. Environmental considerations also advocate for the adoption of ductile iron. As the industry steers toward sustainability, ductile iron presents an eco-friendly alternative due to its recyclability. Many foundries employ sustainable practice methodologies, from recycling scrap metal to minimizing energy consumption during production, which aligns with global environmental goals. Moreover, customization capabilities offer expert solutions tailored to diverse urban demands. From ornate designs catering to heritage sites to anti-theft innovations incorporating locking mechanisms, the versatility of ductile iron casting is unrivaled. Engineers can work directly with city officials or private contractors to design covers that blend aesthetic requirements with practical functions—a balanced solution that speaks to the expertise and credibility of manufacturers in this sector. In conclusion, ductile iron casting has revolutionized manhole cover production, transforming it into a sophisticated, adaptable, and sustainable process fitting modern infrastructure's needs. By leveraging industry-leading expertise and maintaining a commitment to authoritative, trustworthy practices, manufacturers continue to solidify ductile iron’s status as a vital component in urban development, ensuring our cities remain secure, functional, and future-ready. The commitment to quality and innovation keeps ductile iron at the forefront, offering solutions that are not only built to last but also to adapt, embodying the pinnacle of modern engineering marvels.

Advantages of ductile iron castings over their conventional counterparts are manifold. High tensile strength and flexibility mean that ductile iron covers face less likelihood of fracturing under pressure, which enhances safety and longevity. Additionally, the material's ability to absorb vibrations reduces noise pollution—a critical feature for densely populated areas. These functional benefits underscore the trustworthiness of ductile iron as a material of choice, offering peace of mind to urban planners and end-users alike. Environmental considerations also advocate for the adoption of ductile iron. As the industry steers toward sustainability, ductile iron presents an eco-friendly alternative due to its recyclability. Many foundries employ sustainable practice methodologies, from recycling scrap metal to minimizing energy consumption during production, which aligns with global environmental goals. Moreover, customization capabilities offer expert solutions tailored to diverse urban demands. From ornate designs catering to heritage sites to anti-theft innovations incorporating locking mechanisms, the versatility of ductile iron casting is unrivaled. Engineers can work directly with city officials or private contractors to design covers that blend aesthetic requirements with practical functions—a balanced solution that speaks to the expertise and credibility of manufacturers in this sector. In conclusion, ductile iron casting has revolutionized manhole cover production, transforming it into a sophisticated, adaptable, and sustainable process fitting modern infrastructure's needs. By leveraging industry-leading expertise and maintaining a commitment to authoritative, trustworthy practices, manufacturers continue to solidify ductile iron’s status as a vital component in urban development, ensuring our cities remain secure, functional, and future-ready. The commitment to quality and innovation keeps ductile iron at the forefront, offering solutions that are not only built to last but also to adapt, embodying the pinnacle of modern engineering marvels.

Share

Latest news

-

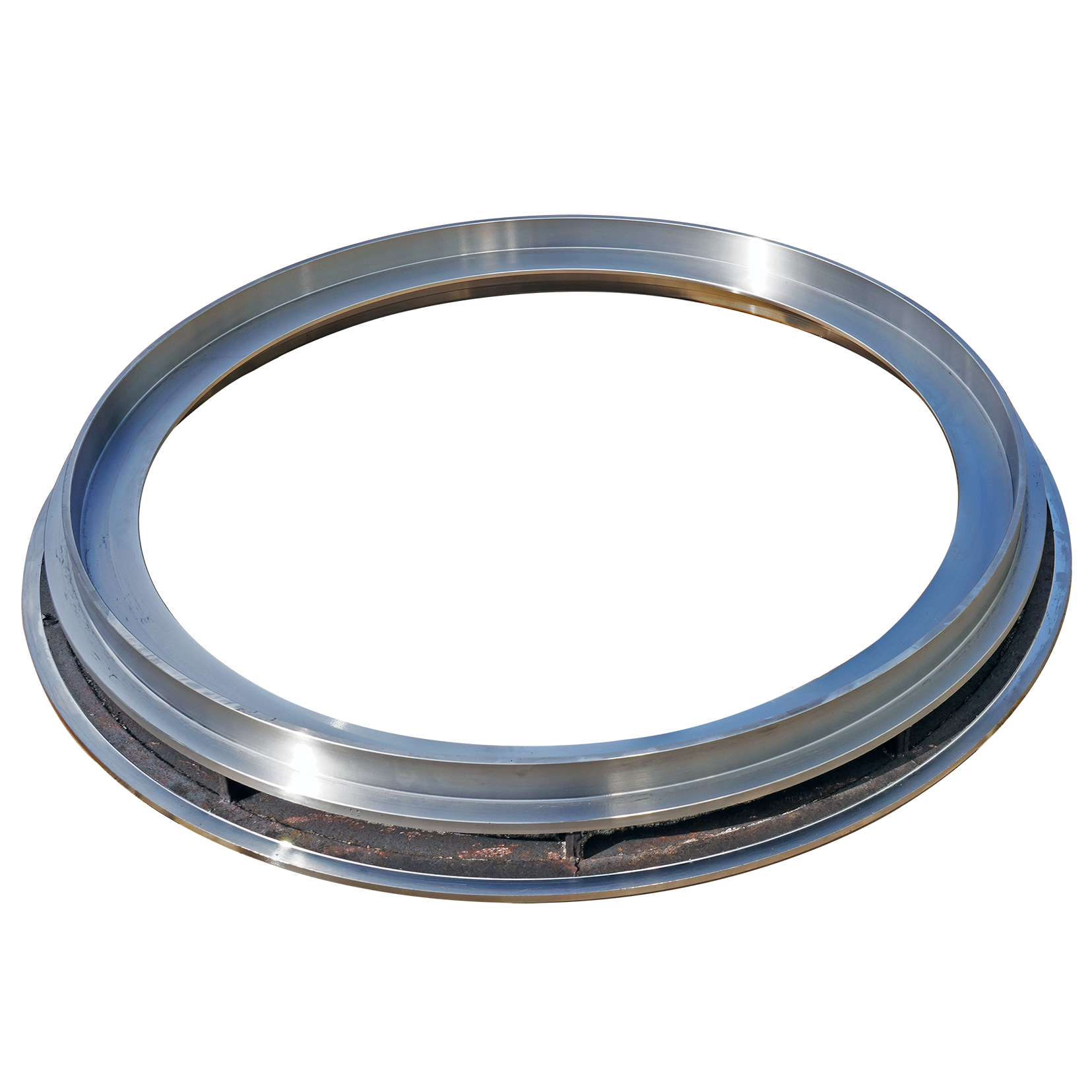

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025