- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Pro . 21, 2024 14:41 Back to list

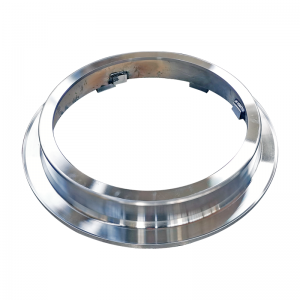

odm casting machinery parts

ODM Casting Machinery Parts Enhancing Precision and Efficiency in Manufacturing

In today's fast-paced manufacturing landscape, the demand for high-quality components that can withstand rigorous operational environments is paramount. One pivotal solution that has emerged to address this need is Original Design Manufacturer (ODM) casting machinery parts. This innovative approach combines the principles of casting with the advantages of customized designs, resulting in enhanced performance, efficiency, and adaptability across various industrial applications.

Understanding ODM Casting

ODM casting refers to the practice where manufacturers design and produce components based on the specifications provided by clients. This allows companies to have parts tailored to their unique requirements without compromising on quality or performance. The casting process, which involves pouring molten metal into a mold to form a desired shape, ensures that the finished products maintain excellent dimensional accuracy and stability, crucial for machinery operation.

Advantages of ODM Casting Machinery Parts

1. Customization One of the most significant advantages of ODM casting is the ability to create custom parts that precisely meet the specific needs of a business. This level of customization can lead to better fitting components, reducing the risk of malfunctions or wear and tear, thereby extending the lifespan of machinery.

2. Cost-Effectiveness While initial setup costs may be higher than using off-the-shelf parts, ODM casting can lead to significant savings in the long run. Customized parts often require fewer adjustments during assembly and can lead to reduced downtime, translating to overall cost savings.

3. Enhanced Performance ODM casting allows manufacturers to optimize the material composition and design of their parts for specific applications. This means that machinery can operate more efficiently, leveraging parts that are best suited to handle the demands of particular operational settings.

odm casting machinery parts

4. Rapid Prototyping The ability to quickly prototype and iterate designs is another crucial benefit of ODM casting. This flexibility allows businesses to test various configurations and materials rapidly, leading to quicker product development cycles and reduced time-to-market for new machinery.

5. Sustainability By investing in ODM casting solutions, companies can produce components that are designed for longevity and efficiency. This focus on durability aligns with a growing emphasis on sustainability in manufacturing, helping businesses reduce waste and environmental impact over time.

Applications of ODM Casting Machinery Parts

ODM casting machinery parts find applications across numerous industries, including automotive, aerospace, textiles, and heavy machinery. For instance, in the automotive sector, precision-engineered components such as engine blocks, transmission cases, and suspension parts can significantly enhance vehicle performance and reliability. Similarly, in aerospace, lightweight yet strong components are crucial for fuel efficiency and safety.

Moreover, industries such as construction and mining rely heavily on durable casting parts for machinery like excavators and bulldozers. The ability to tailor these parts to withstand specific environmental challenges—such as extreme temperatures, heavy loads, or corrosive conditions—demonstrates the versatility and importance of ODM casting in these fields.

Conclusion

In conclusion, ODM casting machinery parts are revolutionizing the way components are designed and produced, offering manufacturers unmatched customization, performance, and efficiency. As industries continue to evolve and face increasingly complex challenges, leveraging ODM casting can lead to innovations that not only meet but exceed current demands. By investing in customized casting solutions, businesses stand to gain a competitive edge, ensuring that they are well-equipped to tackle the future of manufacturing. Whether in the automotive sector or beyond, the transformation brought about by ODM casting is paving the way for a more precise, efficient, and sustainable industrial landscape.

-

Durable Cast Iron Water Main Pipe | AI-Optimized Design

NewsAug.05,2025

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025