- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Zář . 25, 2024 17:27 Back to list

precision machining suppliers

Precision Machining Suppliers The Backbone of Modern Manufacturing

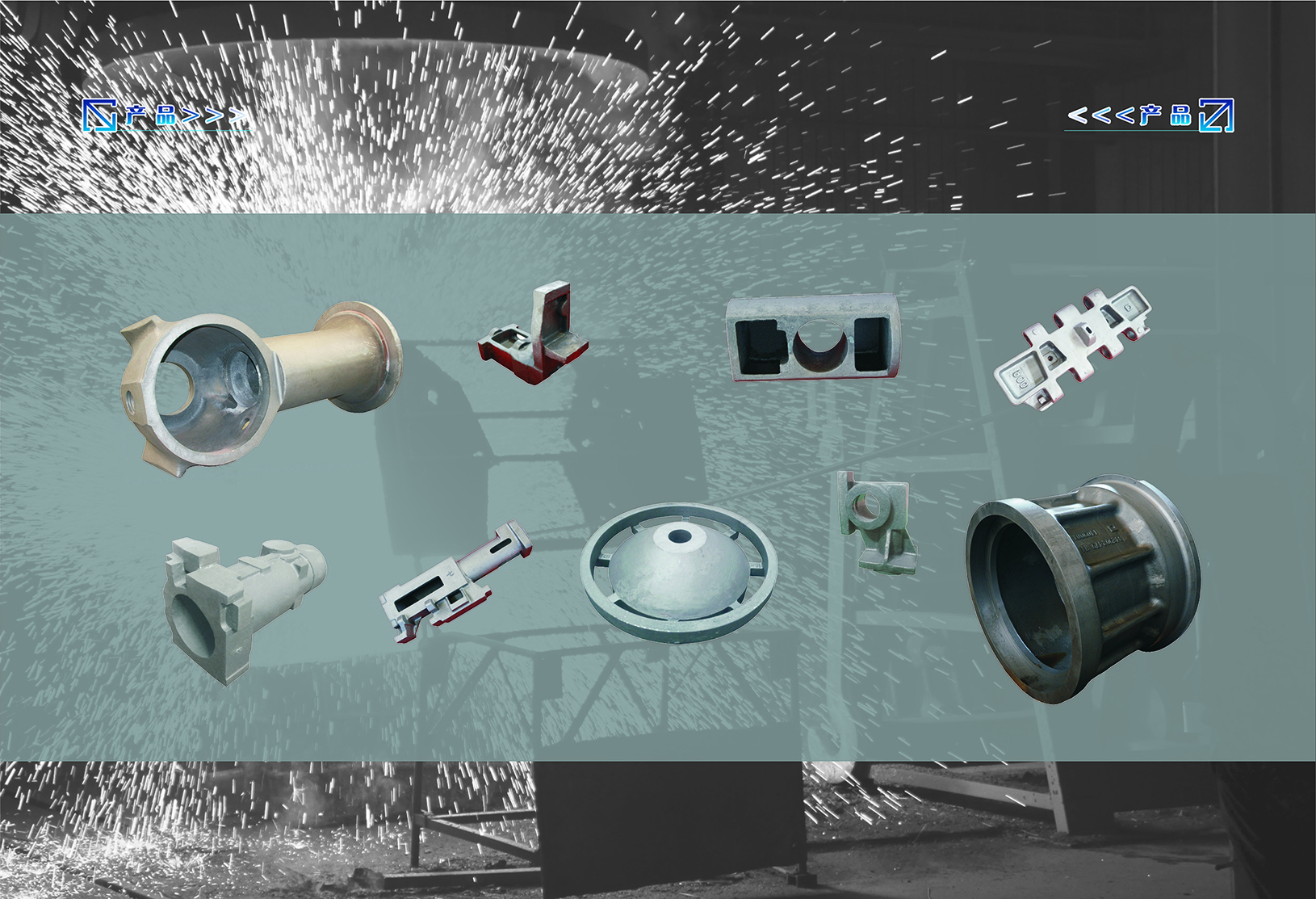

In today's fast-paced and highly competitive manufacturing environment, precision machining has become a cornerstone of production across numerous industries. Precision machining refers to the process of fabricating parts with high accuracy and tight tolerances, essential for applications in aerospace, automotive, medical devices, and electronics, among others. The significance of precision machining suppliers cannot be overstated, as they provide the expertise, technology, and resources necessary for businesses to thrive.

Understanding Precision Machining

Precision machining involves various methods, including turning, milling, grinding, and electrical discharge machining (EDM). These processes utilize advanced machinery, such as CNC (Computer Numerical Control) machines, which enable manufacturers to produce intricate components with minimal human intervention. Key to the effectiveness of these processes is the ability to maintain tolerances often within thousandths of an inch. Such precision is crucial for ensuring that parts fit seamlessly into larger assemblies, maintain functional reliability, and uphold safety standards.

The Role of Suppliers in Precision Machining

Suppliers play a vital role in the precision machining landscape by offering not only raw materials but also specialized machinery, tools, and quality control services. A reliable precision machining supplier is an essential partner for manufacturers seeking to enhance productivity and reduce lead times. Here are some of the key attributes that set exceptional suppliers apart

1. Quality of Materials The raw materials used in precision machining, such as alloys, plastics, and composites, must meet strict quality standards. Top suppliers often provide materials that are certified to meet industry-specific requirements, ensuring that the final products are durable and reliable.

2. Advanced Technology As technology continually evolves, the best suppliers invest in state-of-the-art machinery and software. This investment allows them to offer services such as 5-axis machining, which enables the creation of complex geometries that would be impossible with traditional methods. Suppliers that stay ahead of technological trends are invaluable to manufacturers looking to gain a competitive edge.

precision machining suppliers

3. Expertise and Support Precision machining is a complex field that requires deep knowledge and experience. Suppliers with skilled technicians and engineers can offer insights that help manufacturers optimize their processes, troubleshoot issues, and innovate their designs. This level of support contributes significantly to reducing waste and improving efficiency.

4. Flexibility and Customization As industries demand ever more specialized solutions, the ability to offer customized machining services becomes crucial. Top suppliers work closely with their clients to understand specific needs and constraints, adjusting their processes to deliver bespoke solutions that meet unique specifications.

5. Adherence to Standards Compliance with industry standards and regulations is vital in precision machining. The best suppliers are ISO certified and adhere to rigorous quality management systems. They conduct frequent audits and inspections to ensure that their processes consistently meet or exceed the necessary standards, thus providing peace of mind to their clients.

Challenges Faced by Precision Machining Suppliers

Despite the wealth of opportunities in the precision machining sector, suppliers face significant challenges. The industry is often subject to fluctuating demand, which can make it difficult to maintain a steady workflow. Additionally, the rising costs of raw materials and skilled labor pose ongoing challenges. Suppliers must also navigate the increasing complexity of customer requests while ensuring quality and efficiency.

Conclusion

Precision machining suppliers are indispensable partners in the world of modern manufacturing. Their role in providing quality materials, advanced technology, expert support, and customized solutions cannot be understated. As industries continue to evolve, the demand for precision machining will only increase, making the choice of a reliable supplier more important than ever. By fostering strong relationships with their suppliers, manufacturers can enhance their operations, drive innovation, and ultimately achieve greater success in a competitive marketplace. In summary, precision machining suppliers not only enable the production of high-quality components but also empower manufacturers to push the boundaries of what is possible in their respective fields.

-

Silica Sol Casting Supplier – Custom, ODM & Buy Services High Precision Casting Solutions

NewsJun.10,2025

-

High-Performance AODD Pumps for Diverse Applications Buy Custom & ODM AODD Solutions Online

NewsJun.10,2025

-

High-Quality Casting Machinery Parts Custom & ODM Services Available

NewsJun.10,2025

-

Premium Punching Cement Concrete Pipe Mold Pallets Custom ODM Available

NewsJun.10,2025

-

Premium Cast Aluminum Silicon Radiator Castings For Sale

NewsJun.10,2025

-

Custom Cast Steel Pipe Mold Pallet for Durable Precision

NewsJun.10,2025