Pro . 12, 2024 17:38 Back to list

Understanding Shell Molding Casting Techniques for Precision Metal Parts Production

Shell molding casting, a sophisticated technique in the field of foundry practices, has gained recognition for its efficiency and high-quality output. This method combines traditional metal casting with modern technology to produce precise and durable metal components. In this article, we will explore the process of shell molding casting, its advantages, applications, and the future of this innovative manufacturing technique.

What is Shell Molding Casting?

Shell molding casting is a type of precision casting that involves creating a thin shell of sand bonded with a resin, which forms the mold for metal pouring. This technique was developed in the 1940s and has since become a popular choice for producing intricate shapes with high-dimensional accuracy. The process typically starts with the creation of a metal pattern, which is heated and then coated with a mixture of fine sand and thermosetting resin. Upon contact with the hot pattern, the resin cures, bonding the sand particles together and forming a rigid shell. After the shell is sufficiently cured, it is removed from the pattern, and the two halves of the mold are assembled to prepare for pouring metal.

Advantages of Shell Molding Casting

One of the primary advantages of shell molding casting is the exceptional surface finish it provides to the final product. The fine-grained sand used in the process produces smooth surfaces, often eliminating the need for secondary machining. Additionally, the precision of shell molds allows for tighter tolerances in the casted parts, making it an ideal choice for components that require high accuracy.

Another significant benefit is the efficiency of the process. The ability to produce molds quickly and with minimal labor leads to reduced lead times, which is crucial in today’s fast-paced manufacturing environment. The quick curing of the resin allows for a higher rate of production, while the durability of the molds enables them to be reused multiple times, making the process economically advantageous.

Moreover, shell molding casting is highly versatile. It can accommodate a wide range of metals, including iron, aluminum, and various alloys. This adaptability makes it suitable for various industries, from automotive to aerospace, where precision and durability are paramount.

Applications of Shell Molding Casting

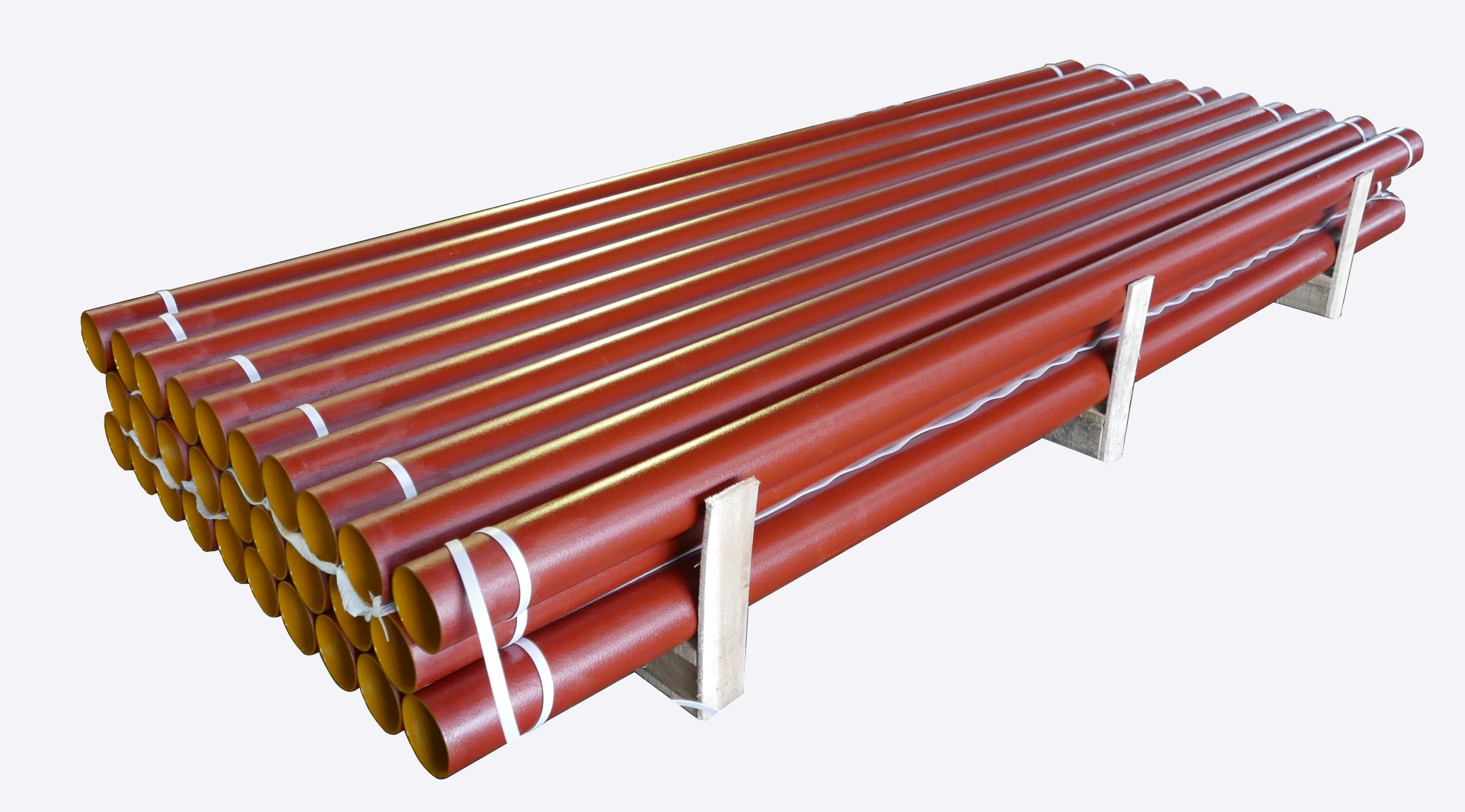

shell molding casting

The applications of shell molding casting span across various sectors. In the automotive industry, it is frequently used to manufacture engine components and other intricate parts that require high strength and dimensional stability. The aerospace sector also relies on shell molding for producing lightweight yet robust components, aiding in the efficiency of aircraft design.

Additionally, the marine industry benefits from shell molding casting, as it allows for the production of complex shapes required for boat motors and other equipment subjected to harsh conditions. The ability to create detailed and durable parts makes shell molding a preferred choice for manufacturers looking for high-quality castings in demanding applications.

The Future of Shell Molding Casting

As technology advances, the future of shell molding casting looks promising. Innovations in materials and automation are expected to enhance the efficiency and quality of this technique further. The integration of computer-aided design (CAD) and computer-aided manufacturing (CAM) systems can lead to even greater precision in mold creation, allowing for the design of more complex shapes and the reduction of human error.

Sustainability is another critical area where shell molding casting can evolve. Efforts are being made to develop eco-friendly resin materials and recycling processes for waste sand, aligning with global trends towards sustainable manufacturing practices. As industries face increasing pressure to reduce their environmental footprint, adopting more sustainable methods will be essential for the future of shell molding casting.

Conclusion

In conclusion, shell molding casting represents a significant advancement in metal casting technology, offering numerous advantages such as excellent surface finish, high precision, and versatility across various applications. As we look to the future, continued innovations in this field promise to drive efficiencies and sustainability, making shell molding an integral part of modern manufacturing. Its ability to meet the demands of various industries while producing high-quality components ensures that shell molding casting will remain a vital process for years to come.

-

Premium Cast Iron Water Main Pipe for Robust Infrastructure

NewsAug.27,2025

-

A-Rated Cast Aluminum Boilers: High-Efficiency Condensing Gas & LPG

NewsAug.26,2025

-

OEM Cast Silicon Aluminum Alloy Heat Exchanger | Custom & High Performance

NewsAug.25,2025

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025