- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Medi . 12, 2024 08:37 Back to list

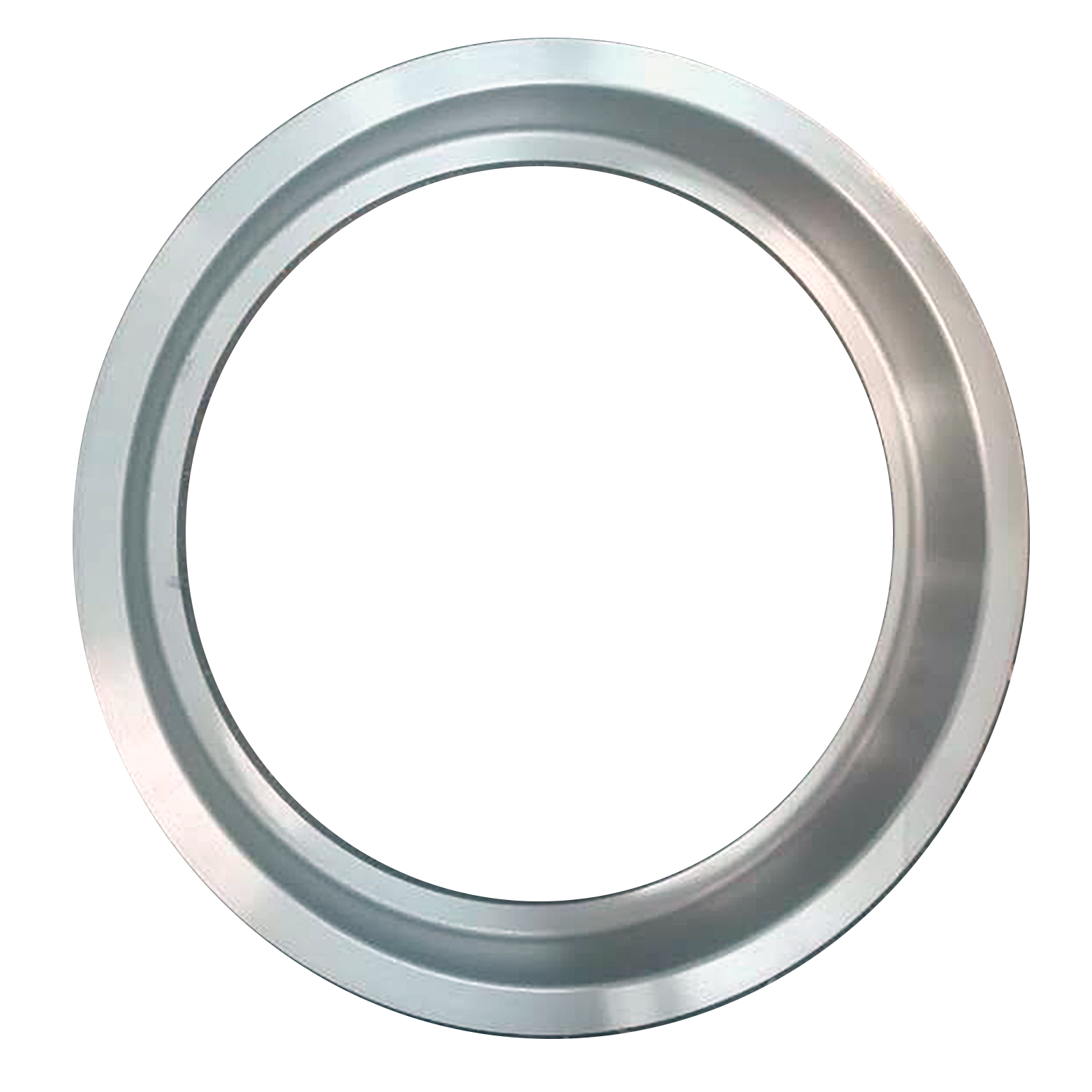

Efficient Heat Exchanger Solutions for Water Cooling

Heat Exchangers for Cooling Water

Heat exchangers play a vital role in various industrial processes, particularly in the efficient management of energy and the cooling of fluids. Among their many applications, cooling water using heat exchangers stands out as an essential function in numerous sectors, including power generation, chemical processing, and HVAC systems. This article explores how heat exchangers facilitate the cooling of water, enhancing operational efficiency and contributing to energy conservation.

Heat Exchangers for Cooling Water

One common type of heat exchanger used for cooling water is the shell-and-tube heat exchanger. This design consists of a series of tubes where one fluid flows through the tubes, while another fluid flows around them, within a larger shell. The heat exchange occurs through the walls of the tubes, allowing heat to transfer from the warmer fluid to the cooler one. This setup is particularly effective for high-capacity applications, making it a favorite in large industrial plants.

heat exchanger to cool water

Another popular design is the plate heat exchanger, which consists of multiple thin plates stacked together. This configuration provides a large surface area for heat transfer in a compact design, making it ideal for applications with limited space. Plate heat exchangers are often employed in HVAC systems and food processing industries, where precise temperature control is crucial.

The cooling of water through heat exchangers offers several advantages. First, it significantly reduces energy consumption by lowering the temperature of working fluids, which can decrease the overall energy demand for cooling processes. Furthermore, this technology enables organizations to recycle water, thus conserving vital resources and reducing operational costs associated with water treatment and disposal.

Moreover, modern heat exchangers are often equipped with advanced control systems that optimize their performance. These systems can adjust flow rates and temperatures based on real-time data, ensuring that the cooling process is both efficient and responsive to changing operational conditions. This dynamic capability not only enhances efficiency but also prolongs the lifecycle of the equipment by reducing wear and tear.

In conclusion, heat exchangers are indispensable in the cooling of water across various industries. Their ability to efficiently transfer heat helps in conserving energy and resources while minimizing environmental impact. As technology advances, the design and effectiveness of heat exchangers continue to improve, further solidifying their role in sustainable industrial practices. The ongoing development in this field offers promising prospects for achieving greater energy efficiency, contributing to a more sustainable future in industrial operations.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025