- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Οκτ . 11, 2024 13:55 Back to list

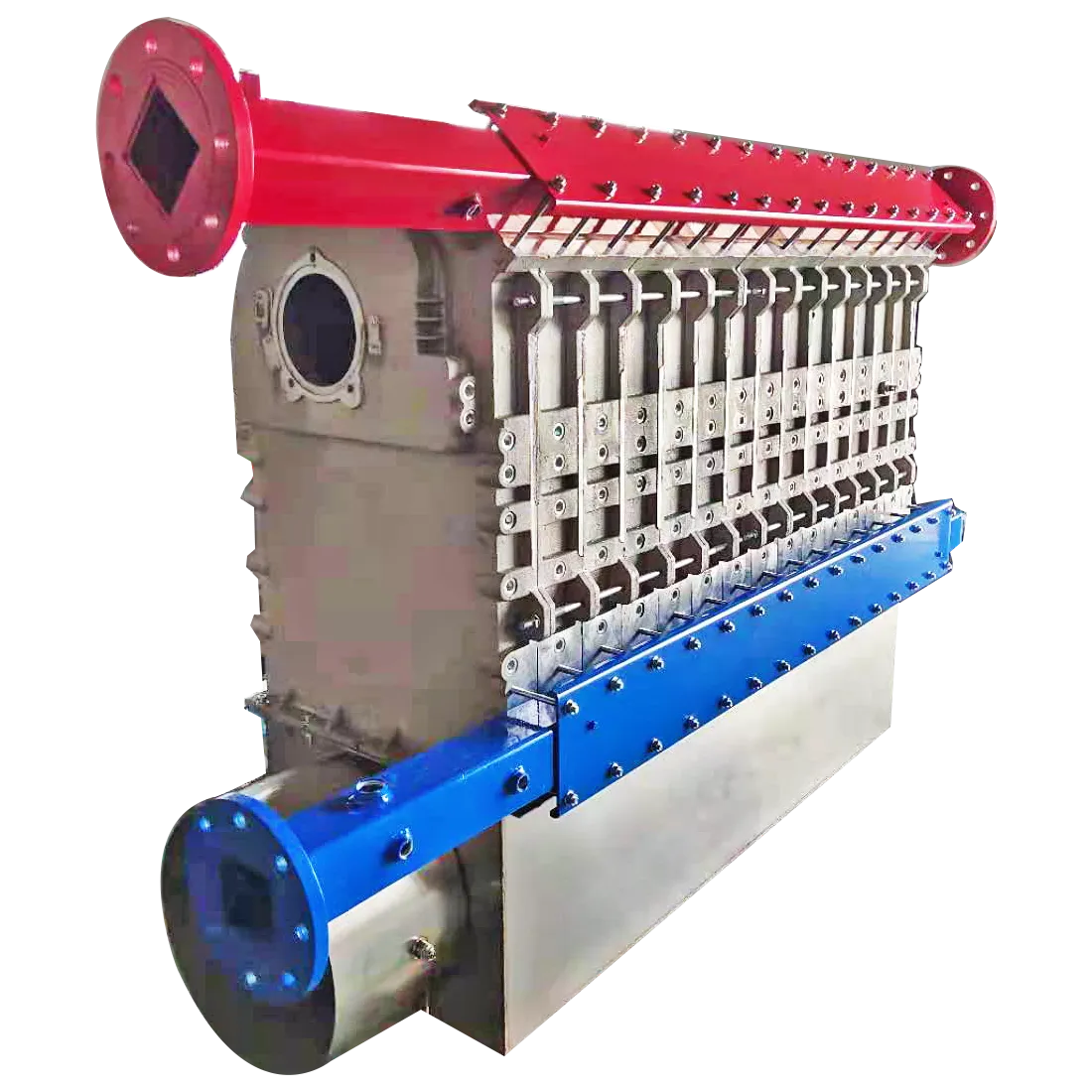

china gas fired boiler made from cast silico aluminum heat exchanger

The Emergence of Cast Silico Aluminum Heat Exchangers in China’s Gas-Fired Boilers

In recent years, China has emerged as a prominent player in the global energy landscape, particularly in the production and utilization of gas-fired boilers. Among the innovative technologies driving this sector forward is the development of heat exchangers made from cast silico aluminum. This material choice not only enhances efficiency but also extends the lifespan of these critical components in gas-fired boilers.

Gas-fired boilers are widely used in residential, commercial, and industrial settings due to their lower emissions and efficient operation compared to traditional coal-fired boilers. The shift towards cleaner energy sources has prompted manufacturers to seek advanced materials that can withstand high temperatures and corrosive environments. Cast silico aluminum has gained traction as an ideal solution for heat exchangers in these systems.

One of the primary advantages of cast silico aluminum is its excellent thermal conductivity. This characteristic ensures efficient heat transfer, which is crucial in optimizing the performance of gas-fired boilers. By facilitating quicker heat exchange, boilers can achieve higher efficiency ratings, leading to reduced fuel consumption and lower operating costs. In a country like China, where energy costs significantly impact the economy, improving boiler efficiency can have substantial financial implications for both consumers and businesses.

china gas fired boiler made from cast silico aluminum heat exchanger

Moreover, the durability of cast silico aluminum is another key benefit. This alloy exhibits excellent resistance to oxidation and corrosion, which are common challenges faced by traditional materials in high-heat applications. The longevity of equipment directly correlates with maintenance costs; thus, manufacturers can save considerable expenses by utilizing heat exchangers made from this advanced material. In an industry where reliability is paramount, the resilience of cast silico aluminum offers peace of mind to operators and stakeholders alike.

Environmental considerations are also at the forefront of this technological shift. As China continues to combat air pollution and promote sustainable practices, the adoption of gas-fired boilers equipped with efficient heat exchangers is a step in the right direction. By maximizing energy efficiency and minimizing emissions, cast silico aluminum heat exchangers contribute to China’s broader goals of reducing its carbon footprint and meeting international climate commitments.

Furthermore, the growing adoption of smart technologies in industrial equipment, including gas-fired boilers, is likely to further enhance the performance and monitoring of heat exchangers. The integration of sensors and IoT technologies can provide real-time data, allowing operators to optimize their boiler systems and preemptively address maintenance needs. This synergy, coupled with the robust properties of cast silico aluminum, positions Chinese manufacturers at the forefront of innovation in the energy sector.

In conclusion, the utilization of cast silico aluminum heat exchangers in China’s gas-fired boilers represents a significant advancement in boiler technology. With advantages such as improved thermal efficiency, durability, and environmental sustainability, this innovation not only meets the current demands of the market but also aligns with the future direction of energy consumption and production. As China continues to navigate the complexities of energy transition, the integration of such materials will undoubtedly play a crucial role in shaping a cleaner and more efficient energy future.

-

Custom Domestic Hot Water Heat Exchangers Efficient & Durable

NewsMay.24,2025

-

Cast Iron vs. Ductile Iron Differences, Uses & Benefits

NewsMay.24,2025

-

Top Gas Fired Boiler Supplier High-Efficiency Solutions & OEM Support

NewsMay.23,2025

-

Marine Gear Box Casting Solutions Durable & Custom OEM/ODM

NewsMay.23,2025

-

Custom Cast Iron Pipe Mold Bottom Ring Durable & ODM Solutions

NewsMay.22,2025

-

Precision nvestment Casting Services – Custom & ODM Solutions

NewsMay.22,2025