- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Ιαν . 16, 2025 02:04 Back to list

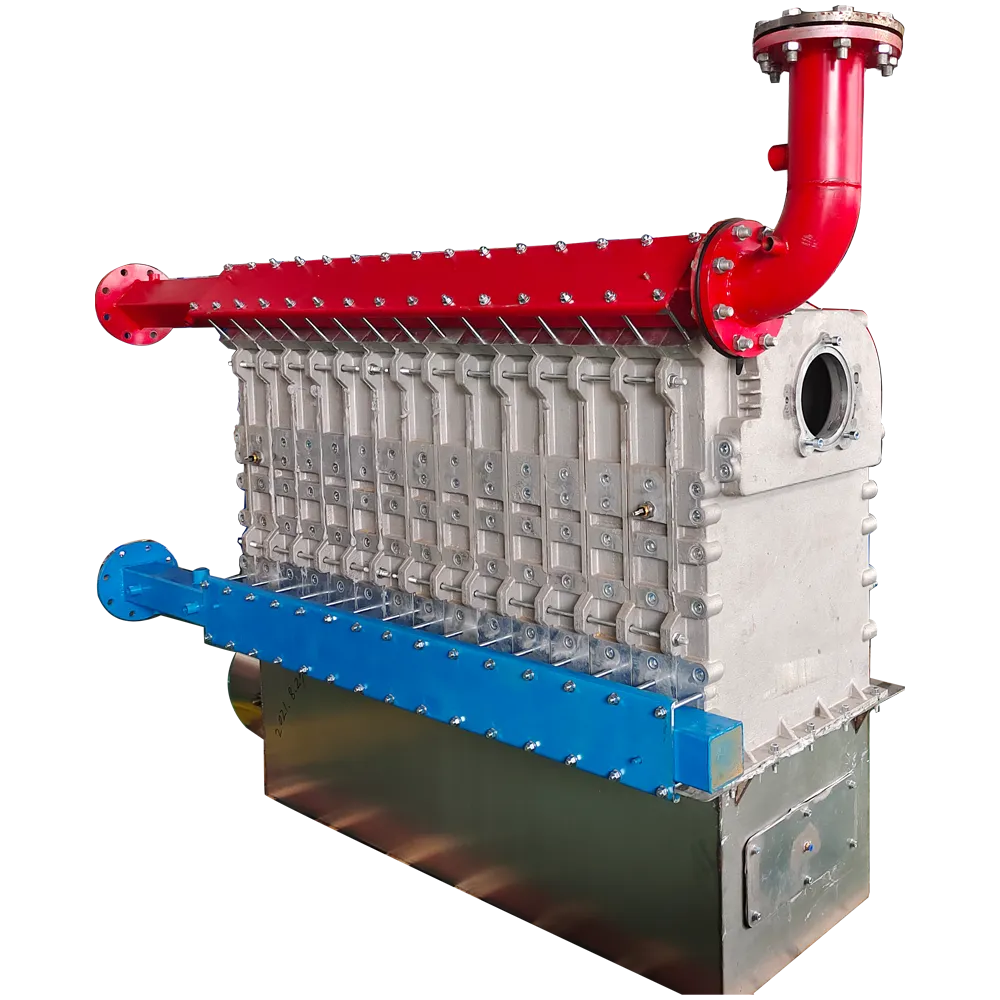

milling frame casting

In the intricate realm of manufacturing, milling frame casting stands as a critical process that merges the accuracy of milling with the strength of casting to produce high-quality, durable components. The fusion of these two processes caters to industries requiring top-tier precision, such as aerospace, automotive, and heavy machinery. Leveraging the strengths of both methods ensures that the end products not only meet but exceed industry standards in terms of reliability and performance.

Milling frame casting isn't just about creating a part; it's about creating a part that is resilient, precise, and dependable. The expertise required in both casting and milling is profound, demanding a comprehensive understanding of material science, engineering principles, and machine operations. Professionals involved in these processes must possess a blend of experience and knowledge, ensuring that each piece produced stands up to scrutiny and meets rigorous quality standards. The authoritative standing of milling frame casting is further solidified by ongoing research and development. The field is continuously evolving with advancements in technology that push the boundaries of what is possible. With the integration of AI and IoT in manufacturing practices, machining processes are becoming smarter and more efficient. Such innovations underscore the authoritative nature of this manufacturing domain, as it not only meets present demands but also anticipates future challenges and opportunities. Trustworthiness in milling frame casting is achieved through stringent quality control measures and adherence to international manufacturing standards. Every stage of the process is meticulously monitored to guarantee that each component aligns with the specified requirements. The credibility is further bolstered by certifications and audits from leading industry bodies, assuring clients and stakeholders of the product's integrity. In conclusion, milling frame casting exemplifies a sophisticated blend of craftsmanship and technology, producing components critical for advanced industrial applications. As industries evolve, the need for such precise and resilient manufacturing methods will continue to grow, underscoring the importance of expertise, authoritativeness, and trustworthiness in the ever-advancing world of industrial manufacturing.

Milling frame casting isn't just about creating a part; it's about creating a part that is resilient, precise, and dependable. The expertise required in both casting and milling is profound, demanding a comprehensive understanding of material science, engineering principles, and machine operations. Professionals involved in these processes must possess a blend of experience and knowledge, ensuring that each piece produced stands up to scrutiny and meets rigorous quality standards. The authoritative standing of milling frame casting is further solidified by ongoing research and development. The field is continuously evolving with advancements in technology that push the boundaries of what is possible. With the integration of AI and IoT in manufacturing practices, machining processes are becoming smarter and more efficient. Such innovations underscore the authoritative nature of this manufacturing domain, as it not only meets present demands but also anticipates future challenges and opportunities. Trustworthiness in milling frame casting is achieved through stringent quality control measures and adherence to international manufacturing standards. Every stage of the process is meticulously monitored to guarantee that each component aligns with the specified requirements. The credibility is further bolstered by certifications and audits from leading industry bodies, assuring clients and stakeholders of the product's integrity. In conclusion, milling frame casting exemplifies a sophisticated blend of craftsmanship and technology, producing components critical for advanced industrial applications. As industries evolve, the need for such precise and resilient manufacturing methods will continue to grow, underscoring the importance of expertise, authoritativeness, and trustworthiness in the ever-advancing world of industrial manufacturing.

Share

Pervious:

Next:

Latest news

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025

-

Durable Cast Iron Water Main Pipe | Buy Ductile Pipe

NewsAug.06,2025