- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

nov . 04, 2024 18:57 Back to list

Top Mould Pallet Producers for Efficient Manufacturing Solutions

Understanding Mould Pallet Manufacturers An Essential Component in the Production Industry

In the world of manufacturing, efficiency and precision play pivotal roles in ensuring high-quality products and streamlined operations. One critical but often overlooked aspect of this intricate machinery is the mould pallet. Mould pallets are essential support structures used in various applications, particularly in the production of concrete items such as slabs, blocks, and pavers. In this article, we will delve into the significance of mould pallet manufacturers and what to consider when choosing a supplier for these indispensable tools.

The Role of Mould Pallets

Mould pallets provide a stable platform for casting and curing concrete products. They serve multiple functions, including

1. Support and Stability Mould pallets must bear the weight of the concrete mixture without warping or fracturing. This stability ensures that the final product maintains its intended shape and dimensions.

2. Durability Given the rigorous conditions in which mould pallets operate, they must be made from robust materials that can withstand wear and tear. High-quality mould pallets ensure longevity, reducing the need for frequent replacements and minimizing operational downtime.

3. Ease of Handling Mould pallets should be designed for easy handling and transportation. Manufacturers often include features such as fork-lift holes or eyelets, making it simpler to move pallets around the production facility.

Choosing the Right Mould Pallet Manufacturer

When selecting a mould pallet manufacturer, several factors should be taken into account to ensure that you receive products that meet your specific needs

1. Experience and Reputation It is vital to consider the manufacturer’s experience in the industry. A well-established company with a solid reputation is more likely to provide high-quality products. Research customer reviews and testimonials to gauge their reliability and service quality.

mould pallet manufacturers

2. Quality of Materials The materials used in the production of mould pallets significantly influence their performance and lifespan. Ensure that the manufacturer employs materials that are resistant to cracking, chipping, and other forms of damage. Common materials include steel, aluminum, and high-density polyethylene (HDPE).

3. Customization Options Every manufacturing process is unique, and so are the requirements for mould pallets. A proficient manufacturer should offer customization options to tailor their products to fit the specific dimensions, weight capacities, and uses that your production line demands.

4. Technological Integration In today’s fast-paced manufacturing environment, technological advancements can enhance efficiency. Look for manufacturers that incorporate innovative designs and production techniques, such as automation in the manufacturing process, to deliver superior products.

5. Sustainability Practices With an increasing focus on sustainability, consider manufacturers that prioritize eco-friendly practices in their production processes. This could include using recycled materials or employing energy-efficient manufacturing techniques.

6. After-Sales Support A reliable mould pallet manufacturer should offer robust after-sales support. This includes guidance on product maintenance, warranty options, and assistance with any issues that may arise during their use.

Industry Trends and Innovations

The mould pallet manufacturing industry is continually evolving with new trends and innovations. Among these, the use of composite materials is gaining popularity due to their lightweight yet durable nature. Additionally, advancements in digital technology, such as 3D printing and computer-aided design (CAD), are enabling manufacturers to create more precise and customized mould pallets.

Conclusion

Mould pallets may seem like a minor component within the vast machinery of the manufacturing process, yet their importance cannot be overstated. With the right mould pallet manufacturer, businesses can enhance production efficiency, reduce costs, and improve the quality of their end products. Investing time and resources into finding a manufacturer that meets your needs will significantly impact your operations in the long run. As the industry continues to innovate, keeping an eye on trends and advancements will ensure that your production processes remain competitive and efficient. Whether you are a small-scale producer or a large manufacturing plant, understanding the role and selecting the right supplier for mould pallets is essential for maintaining a seamless, productive operation.

-

Steel Reinforced Concrete Pipe Bottom Ring Moulds Buy Custom Solutions

NewsMay.19,2025

-

Original Concrete Pipe Mold Bottom Ring & Pallet Chinese Factory Direct Sale

NewsMay.19,2025

-

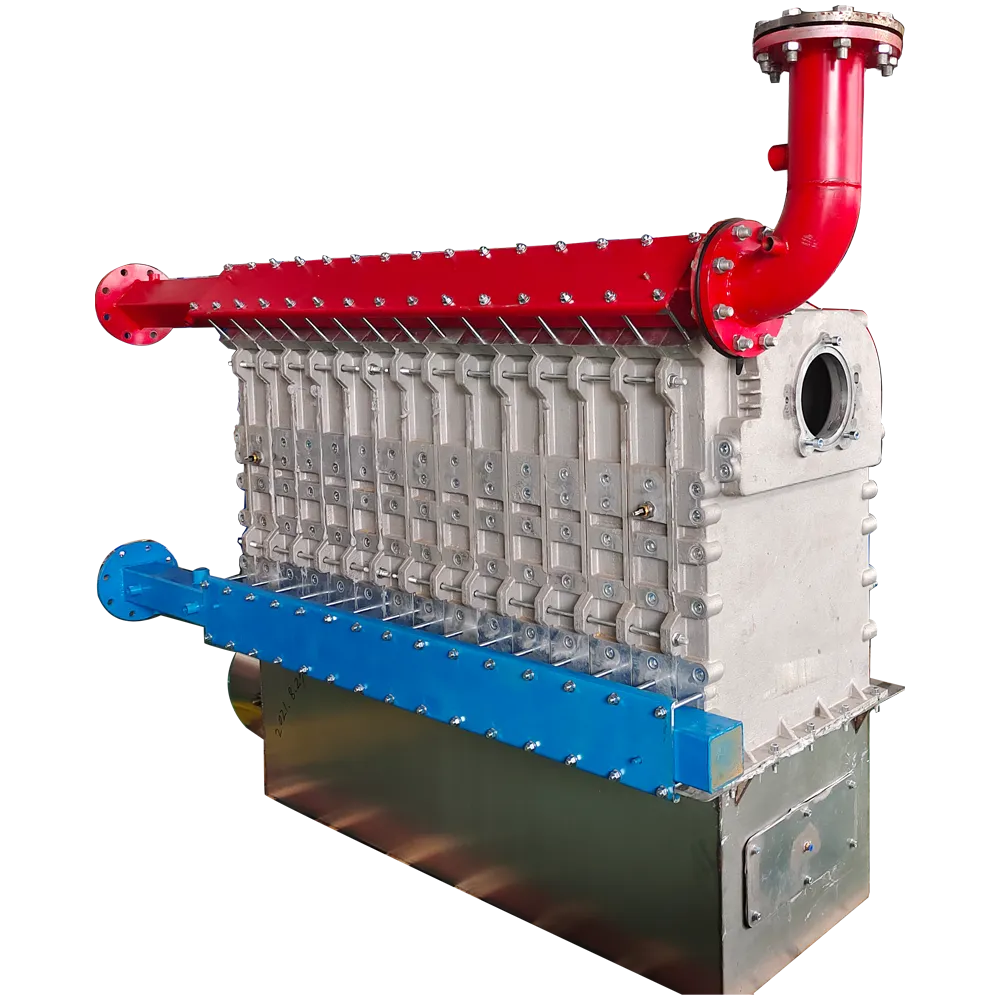

Custom Room Heating Heat Exchangers Energy-Efficient Solutions

NewsMay.18,2025

-

Precision Milling Body Casting Solutions Custom & ODM Options

NewsMay.18,2025

-

Custom Cast Silicon Aluminum Heat Exchanger for Hot Water Boiler High Efficiency

NewsMay.18,2025

-

Premium Custom & ODM Vehicle Parts Bulk Order Deals

NewsMay.17,2025