- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

okt. . 30, 2024 21:00 Back to list

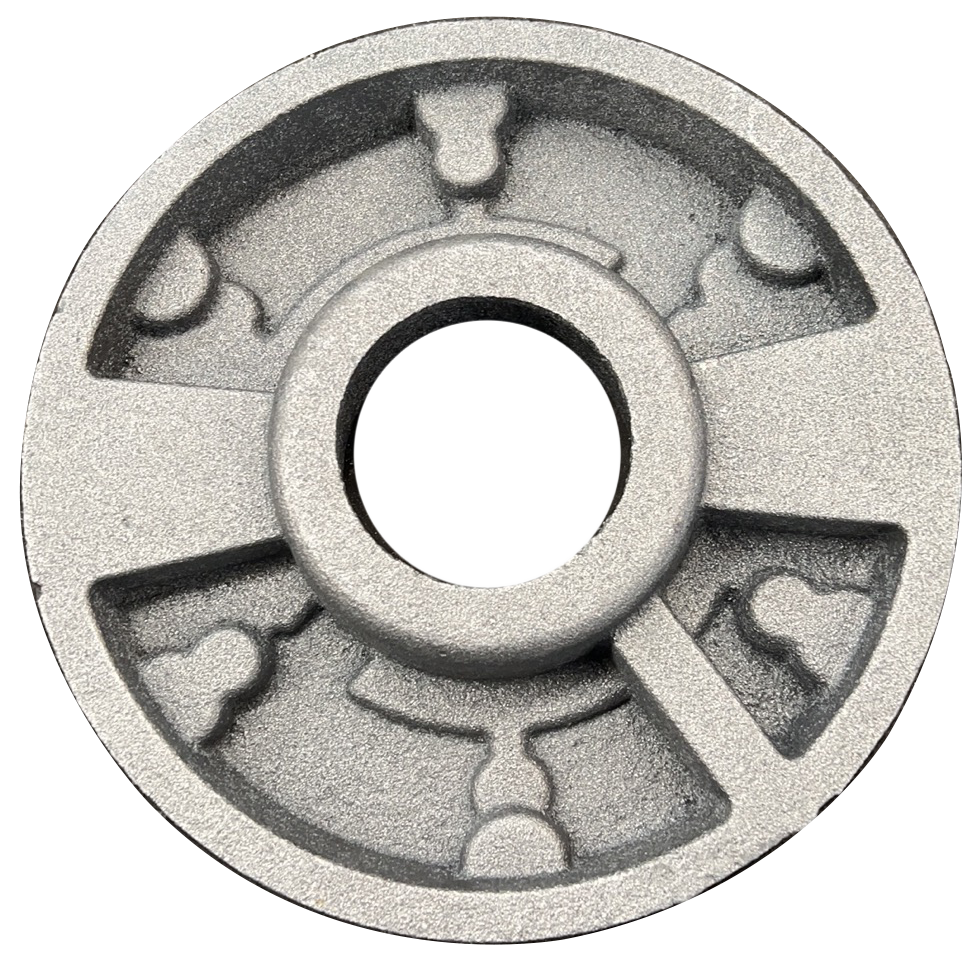

cast steel pipe mold bottom ring manufacturer

The Essential Role of Cast Steel Pipe Mold Bottom Rings in Manufacturing

In the ever-evolving landscape of manufacturing, the significance of durable and reliable components cannot be overstated. One such essential component is the cast steel pipe mold bottom ring, which plays a pivotal role in the production of various steel products. This article delves into the importance of these rings, their manufacturing processes, and the leading manufacturers in the industry.

Cast steel pipe mold bottom rings are crucial in shaping and supporting the molds used to produce steel pipes. These rings provide structural integrity, ensuring that the mold retains its shape during the casting process. Their robust construction allows them to withstand high temperatures and pressures, making them ideal for applications in foundries and manufacturing facilities. The quality of the bottom ring directly impacts the efficiency and effectiveness of the entire casting operation.

The manufacturing process of cast steel pipe mold bottom rings involves several critical steps. Initially, high-grade raw materials, typically carbon or alloy steel, are selected to ensure strength and durability. The material is then melted down in a furnace, reaching temperatures exceeding 1500 degrees Celsius. Once the metal is in a molten state, it is poured into molds formulated to create the specific shape and dimensions of the bottom ring. After cooling, the rings undergo finishing processes, which may include machining and surface treatments to enhance their performance and longevity.

cast steel pipe mold bottom ring manufacturer

A handful of manufacturers have distinguished themselves in the production of these vital components. Companies dedicated to precision engineering utilize advanced technologies and state-of-the-art facilities to produce high-quality cast steel pipe mold bottom rings. These manufacturers often focus on research and development to innovate and improve their products continually. They adhere to strict quality control processes, ensuring that each ring meets industry standards before it is dispatched for use.

In addition to their core functionality, cast steel pipe mold bottom rings contribute to the sustainability of manufacturing practices. By utilizing materials that endure over time and withstanding repeated cycles of high-stress casting, manufacturers can reduce waste and lower operational costs.

In conclusion, cast steel pipe mold bottom rings are indispensable in the steel casting industry. Their ability to enhance the efficiency of manufacturing processes while ensuring quality makes them a vital component for modern production. As technology advances, the continual development of these components will undoubtedly play a significant role in driving the industry forward. manufacturers that specialize in this area will remain crucial to the growth and sustainability of the steel production sector.

-

High-Efficiency Domestic Heating Heat Exchangers Custom Designs

NewsMay.21,2025

-

Premium Cast Steel Pipe Mold Bottom Ring Custom & ODM Solutions

NewsMay.21,2025

-

High-Precision Colloidal Silica Casting Solutions Custom & ODM

NewsMay.20,2025

-

High-Efficiency Cast Silico Aluminum Gas Boiler ODM & Custom Solutions

NewsMay.20,2025

-

Steel Reinforced Concrete Pipe Bottom Ring Moulds Buy Custom Solutions

NewsMay.19,2025

-

Original Concrete Pipe Mold Bottom Ring & Pallet Chinese Factory Direct Sale

NewsMay.19,2025