- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

nov. . 05, 2024 17:24 Back to list

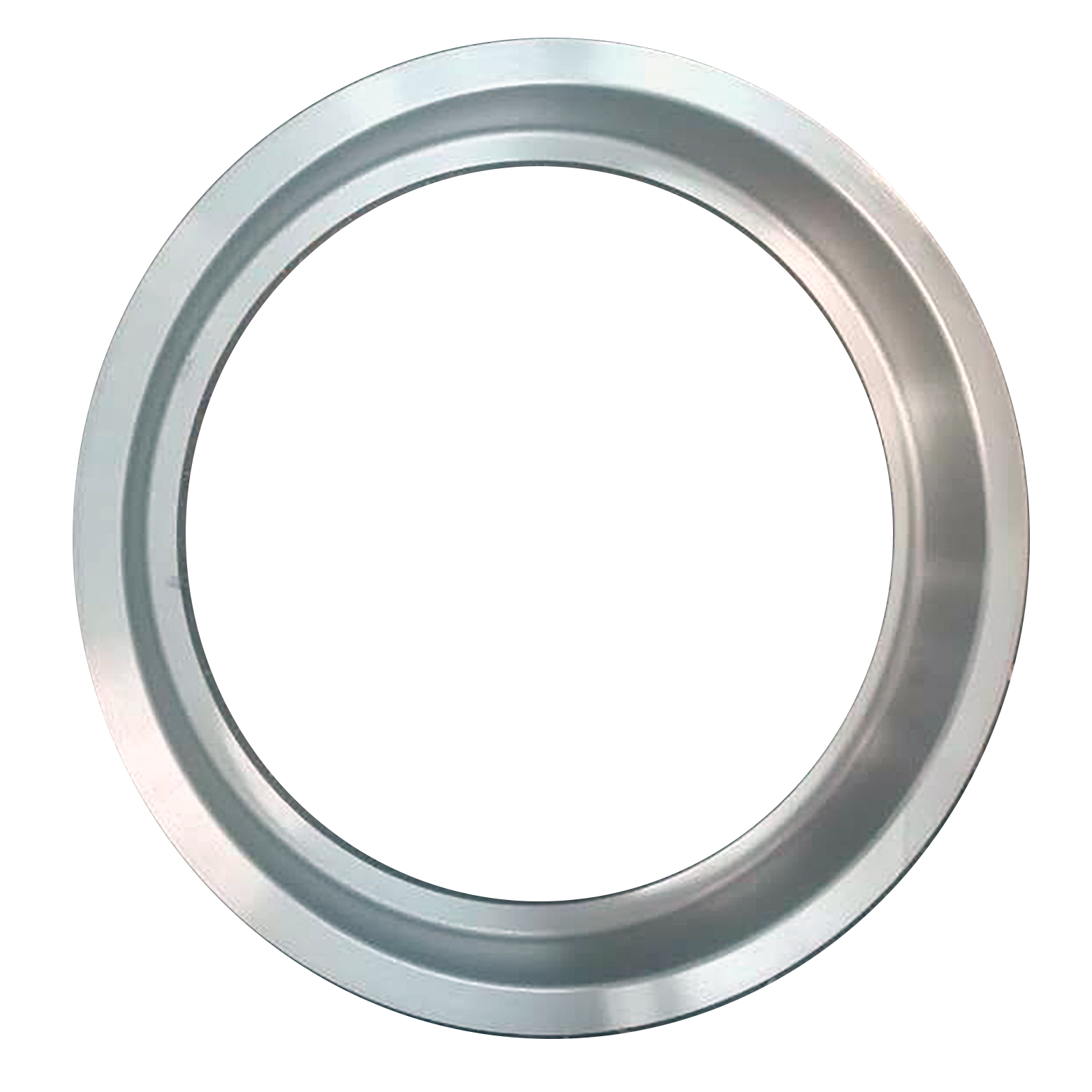

centrifugal casting pipe

Centrifugal Casting Pipe An Innovative Approach to Pipe Manufacturing

Centrifugal casting, also known as centrifuge casting, is a manufacturing process that utilizes centrifugal force to produce cylindrical components with exceptional precision and strength. This technique is particularly advantageous for producing pipes, offering numerous benefits that have propelled its adoption across various industries.

The Process of Centrifugal Casting

The centrifugal casting process begins with the preparation of a cylindrical mold that is typically made from cast iron or steel. The mold is rotated at high speeds around its axis, creating a strong centrifugal force. The molten metal, usually a combination of cast iron, steel, or other alloys, is poured into the spinning mold. As the metal flows into the mold, it is forced against the wall by the centrifugal force, enabling a tightly packed and denser structure.

As the metal cools and solidifies, it forms a pipe with exceptional mechanical properties. The process allows for uniform thickness in the pipe walls and reduces the occurrence of defects such as porosity or inclusions. Once the metal has solidified, the mold is removed, and the resulting pipe is machined to meet specified dimensions, ready for various applications.

Benefits of Centrifugal Casting Pipes

1. Enhanced Material Properties One of the primary advantages of centrifugal casting pipes is the improved mechanical properties of the resulting product. The process fosters a finer grain structure, enhancing strength, ductility, and wear resistance. This is particularly important for pipes used in demanding environments, such as mining and oil drilling, where durability is crucial.

2. Uniformity in Thickness Unlike traditional casting methods, which may lead to irregular thickness, centrifugal casting produces pipes with uniform wall thickness. This uniformity ensures consistent performance and longevity, as the pipes can withstand internal and external pressures efficiently.

3. Reduced Defects The centrifugal force acts to eliminate many common defects associated with traditional casting methods, such as air pockets and inclusions. This leads to a product that not only has superior mechanical properties but also enhanced reliability and safety in use. The reduced need for extensive quality control and testing further contributes to lower production costs.

centrifugal casting pipe

4. Versatility in Materials Centrifugal casting is compatible with various materials, including stainless steel and high-strength alloys. This versatility allows manufacturers to tailor the properties of the pipes according to specific applications, providing customized solutions for different industries.

5. Cost-Effectiveness While the initial setup for centrifugal casting may require a significant investment, the overall production costs can be lower compared to traditional methods. The efficiency of the process, combined with the durability and lower maintenance needs of the pipes, leads to long-term savings for manufacturers and end-users alike.

6. Environmental Considerations With increasing emphasis on sustainability, centrifugal casting offers an environmentally friendly manufacturing alternative. The process generates less waste and uses raw materials more efficiently than many traditional methods, aligning with the growing demand for sustainable practices in manufacturing.

Applications of Centrifugal Casting Pipes

Centrifugal casting pipes are utilized in a wide range of applications across various industries

- Water Supply and Drainage Systems The uniform strength and durability of centrifugal casting pipes make them ideal for constructing water supply and sewage systems. - Oil and Gas Industry These pipes are essential for drilling and transportation processes, where they endure harsh conditions and require high-pressure endurance. - Mining Operations In the mining sector, the sturdiness of centrifugal cast pipes is vital for transporting minerals and handling abrasive materials. - Chemical Processing The corrosion resistance of certain alloys used in centrifugal casting makes these pipes suitable for chemical processing applications.

Conclusion

Centrifugal casting pipes represent a significant advancement in the field of pipe manufacturing. By harnessing the power of centrifugal force, manufacturers can produce pipes with superior mechanical properties, uniform wall thickness, and reduced defects. These advantages translate into greater efficiency, cost savings, and enhanced reliability across various applications. As industries continue to evolve and seek innovative solutions, centrifugal casting pipes will undoubtedly play a pivotal role in meeting the demands of the future.

-

Custom Furniture Hardware Durable & Affordable Solutions Shop Now

NewsJun.01,2025

-

SRC Concrete Pipe Bottom Ring Durable & Customizable Solutions

NewsJun.01,2025

-

Machine Base Casting Solutions Custom & ODM Precision Castings

NewsMay.31,2025

-

Custom Cast Steel Pipe Mould Pallets Heavy-Duty & Custom Solutions

NewsMay.31,2025

-

Cast Silicon Aluminum Alloy Heat Exchanger Suppliers & Exporters

NewsMay.31,2025

-

Precision Die Casting Services Custom & Machining Parts Supplier

NewsMay.31,2025