- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Abe . 25, 2024 10:04 Back to list

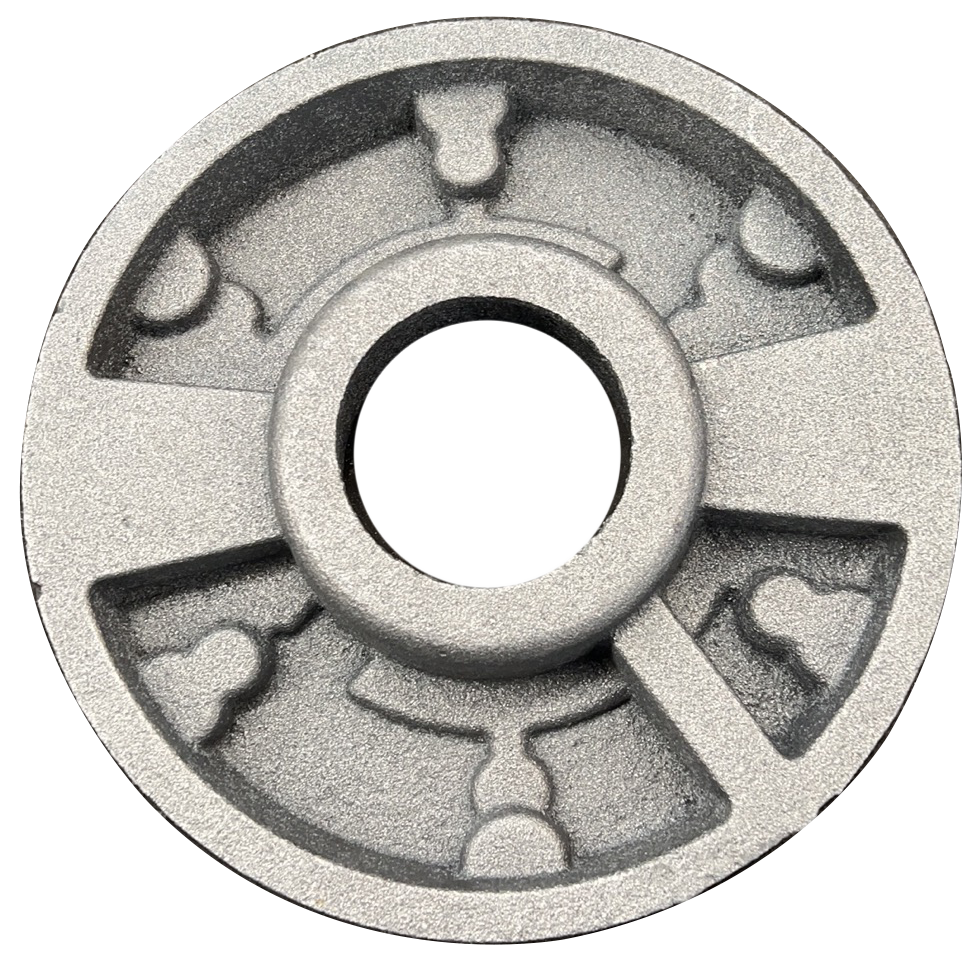

dry cast reinfored concrete pipe mold bottom ring exporter

Exploring the Importance of Dry Cast Reinforced Concrete Pipe Mold Bottom Rings

In the construction and civil engineering industries, the integrity and durability of infrastructure are paramount. One key element that contributes to this durability is the material used for pipes—particularly, dry cast reinforced concrete pipes. Among the components of these pipes is the mold bottom ring, an essential part of the manufacturing process that ensures the pipes' structural quality and longevity.

Understanding Dry Cast Reinforced Concrete Pipes

Dry cast reinforced concrete pipes are manufactured using a technique that utilizes a minimal amount of water during the mixing of raw materials. This method results in a denser, stronger product, which is particularly advantageous for heavy load applications such as stormwater drainage, sewage systems, and culverts. The reinforcement, typically in the form of steel bars or fibers, enhances the tensile strength of the pipes, making them less prone to cracking and deformation under pressure.

The mold bottom ring plays a critical role in this production process. It serves as the foundational component for forming the shape of the pipe during casting. The precision and quality of the mold directly influence the final product's dimensions and strength characteristics.

The Role of Mold Bottom Rings in Pipe Manufacturing

Mold bottom rings not only ensure the right shape but also contribute to the overall performance of the concrete pipes. They are designed to withstand the stresses during the casting and curing phases. When properly engineered, the bottom ring aids in maintaining the alignment and integrity of the pipe, thus preventing imperfections that could weaken the structure.

The design of these bottom rings takes into consideration various factors, including load-bearing capacity, ease of assembly, and durability under harsh manufacturing conditions. Typically made from steel or other robust materials, these rings need to be resistant to wear and tear caused by repeated use in the casting process.

dry cast reinfored concrete pipe mold bottom ring exporter

Quality Control and Exporting of Mold Bottom Rings

When it comes to exporting dry cast reinforced concrete pipe mold bottom rings, quality control is critical. International markets demand high standards of production, and this is especially true in the construction sector, where safety is paramount. Manufacturers aim to adhere to global standards and certifications to ensure their products meet the expectations of foreign clients.

The exporting process involves stringent checks at multiple stages, including the sourcing of raw materials, the manufacturing process itself, and the final inspection before shipment. Ensuring that the mold bottom rings are free from defects is essential, as any flaws could compromise the manufacturing process for pipes and lead to costly failures in the field.

The Future of Dry Cast Reinforced Concrete Pipe Mold Bottom Rings

As the construction industry evolves, so too does the technology and methodology surrounding concrete pipe manufacturing. Innovations such as advanced composite materials and automated production techniques are beginning to take shape. This shift not only improves the quality and lowers production costs but also enhances the sustainability of manufacturing practices.

Moreover, the growing emphasis on sustainable construction has prompted manufacturers to explore eco-friendly materials and processes. This trend is likely to influence the design and production of mold bottom rings in the near future, aligning with global efforts toward reducing carbon footprints within the industry.

Conclusion

The significance of dry cast reinforced concrete pipe mold bottom rings cannot be overstated. They are integral to the effective manufacturing of durable pipes that meet the demands of modern infrastructure. As the construction sector continues to innovate and adapt, the role of these mold rings will evolve, reflecting advancements and sustainability principles that are becoming increasingly important. For manufacturers and exporters alike, focusing on quality, efficiency, and innovation in the production of mold bottom rings holds the key to thriving in a competitive global marketplace. Proper investment in technology and skilled labor will ensure that these components continue to meet and exceed the expectations of the construction industry for years to come.

-

Durable Cast Iron Water Main Pipe | AI-Optimized Design

NewsAug.05,2025

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025