- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Urr . 21, 2024 23:44 Back to list

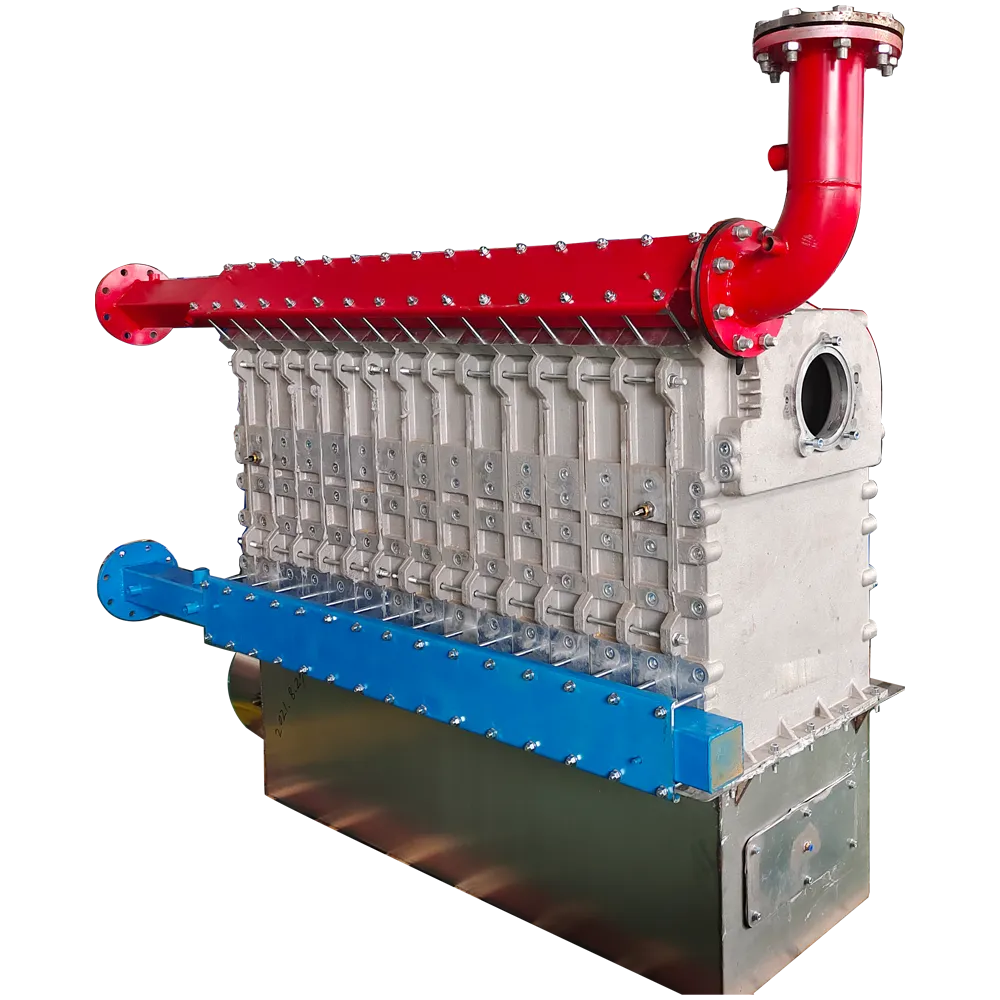

odm iron casting

The Significance of ODM in Iron Casting

In the realm of manufacturing and metallurgy, the term ODM stands for Original Design Manufacturer. This concept plays a vital role in the iron casting industry, where precision, durability, and customization are paramount. Iron casting is a process that involves pouring molten iron into a mold to create various parts and components used in numerous applications, from automotive to industrial machinery. The integration of ODM in iron casting is a game changer, bringing both efficiency and innovation to the industry.

The Significance of ODM in Iron Casting

Moreover, the adoption of ODM in iron casting can significantly streamline the production process. Traditional casting methods can be cumbersome and time-consuming, as they often require multiple iterations to perfect a design. However, ODM allows for simultaneous development and manufacturing, reducing lead times and accelerating the time-to-market. With advanced technology and improved manufacturing techniques, ODM manufacturers can produce high-quality castings quickly, which is invaluable in today’s fast-paced market.

odm iron casting

In addition to efficiency, cost-effectiveness is another crucial aspect of ODM in iron casting. By outsourcing design and production to a specialized ODM provider, companies can save on both labor and material costs. This is particularly beneficial for smaller manufacturers that may not have the resources to invest in extensive design capabilities or state-of-the-art foundries. Instead, they can leverage the expertise and facilities of ODM providers, ensuring high-quality outcomes at a fraction of the cost.

Another significant advantage of using ODM in iron casting is access to advanced technology and innovation. ODM providers are often at the forefront of technological advancements in casting techniques and materials. This access enables clients to benefit from cutting-edge practices, such as 3D printing for molds and the use of lightweight materials, which can enhance the overall performance of the cast products. By partnering with an ODM manufacturer, companies can stay competitive and responsive to evolving market demands.

Quality assurance is paramount in iron casting, and ODM manufacturers take this seriously. They typically adhere to stringent quality control processes to ensure that every component produced meets international standards. This attention to detail and commitment to quality not only helps in minimizing defects but also builds trust with clients, leading to long-term partnerships.

In conclusion, the integration of ODM in the iron casting industry represents a significant advancement in manufacturing. With tailored solutions, streamlined processes, cost savings, access to innovation, and a strong focus on quality, ODM manufacturers are reshaping the landscape of iron casting. As the industry continues to evolve, embracing ODM practices will be essential for companies looking to maintain a competitive edge and meet the ever-growing demands of their clients. In a world that increasingly values customization and efficiency, ODM in iron casting is not just beneficial; it is a necessity.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025