- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

دسامبر . 04, 2024 18:18 Back to list

china sand casting factory

Exploring China's Sand Casting Industry A Look into Factories and Innovations

China, often referred to as the world's manufacturing powerhouse, has established itself as a critical player in the sand casting industry. Sand casting, one of the oldest and most versatile metal casting processes, involves pouring liquid metal into a sand mold to create intricate shapes and components. This method is widely used in various industries, including automotive, aerospace, and machinery, due to its ability to produce complex geometries and its cost-effectiveness.

The Significance of Sand Casting in China

China's sand casting industry plays a vital role in its overall manufacturing ecosystem. With an abundance of raw materials and a vast labor force, the country has developed a robust infrastructure that supports high-volume production. The sand casting process in China is characterized by its efficiency and adaptability, allowing factories to meet both domestic and international demand.

One of the primary reasons for China's dominance in this sector is its investment in cutting-edge technology. Many sand casting factories have adopted advanced methods such as computer-aided design (CAD) and computer-aided manufacturing (CAM) to enhance precision and reduce lead times. This tech-driven approach allows Chinese manufacturers to deliver high-quality products that meet stringent international standards.

A Closer Look at China Sand Casting Factories

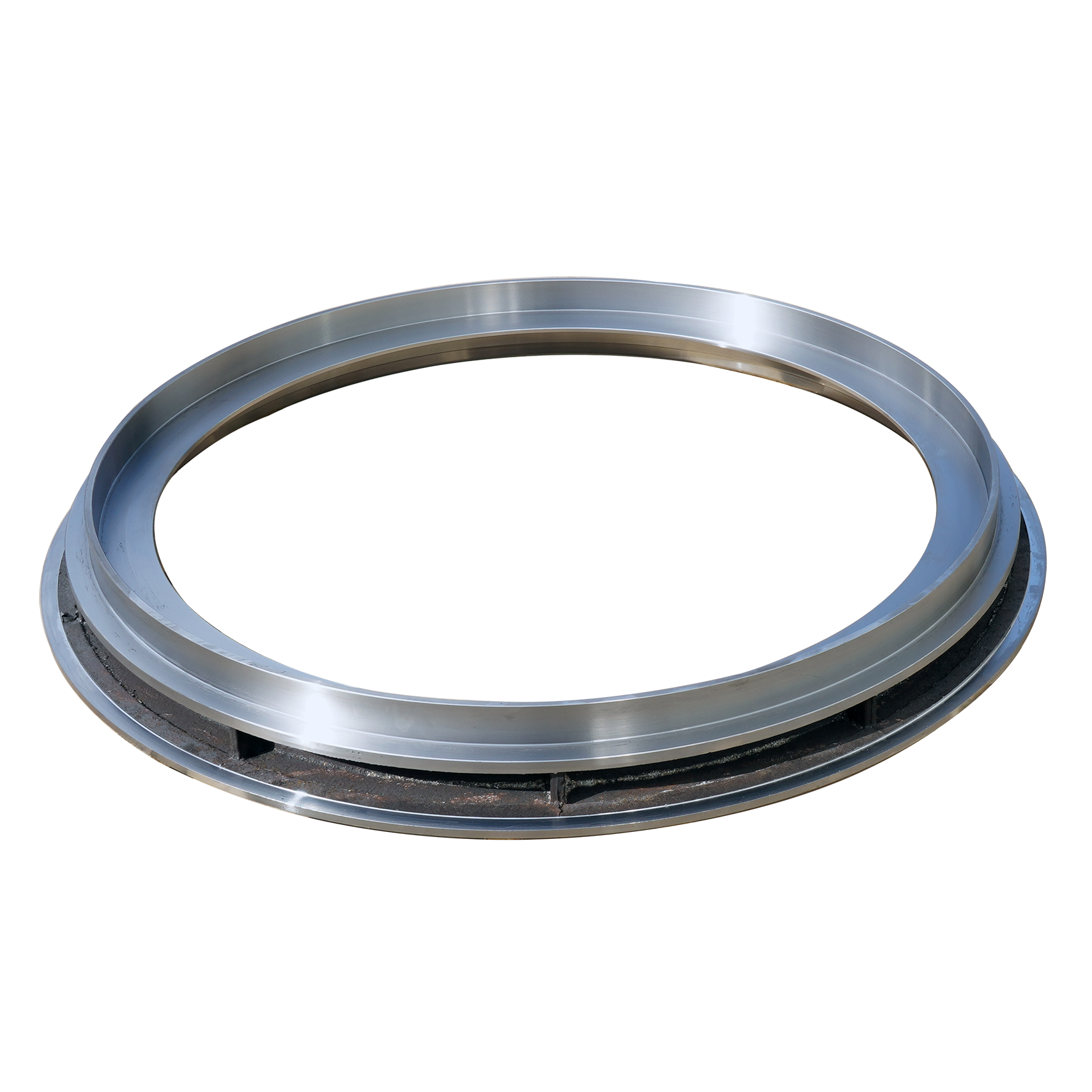

Visitors to Chinese sand casting factories are often impressed by the scale of operations. Large foundries typically boast state-of-the-art equipment, including automatic molding machines, high-temperature furnaces, and sophisticated finishing tools. The production process begins with the creation of a mold, which is made by mixing sand with a binding agent. Following this, molten metal, often aluminum, iron, or steel, is poured into the mold, where it solidifies into the desired shape.

The versatility of sand casting means that it can be used to produce components ranging from small intricate parts to large structural blocks. In particular, the automotive and aerospace industries benefit immensely from this process. Components such as engine blocks, transmission cases, and aircraft engine parts are often produced using sand casting methods.

china sand casting factory

Innovations Shaping the Future of Sand Casting

The future of sand casting in China appears bright due to ongoing innovations. Environmental concerns have prompted many factories to explore sustainable practices. The introduction of eco-friendly binders and recycling processes for sand have become commonplace. Manufacturers are now focusing on reducing waste and minimizing their carbon footprint, aligning with global trends towards sustainability.

Moreover, the rise of additive manufacturing (3D printing) is poised to revolutionize the sand casting landscape. Some Chinese factories have started to integrate 3D printing technology to create molds, which can significantly reduce production time and costs. By using 3D-printed molds, manufacturers can achieve more complex designs and reduce material wastage, leading to increased efficiency.

Quality Control and International Standards

Quality control is paramount in the sand casting industry, particularly for factories producing components for export. Most Chinese sand casting factories implement rigorous inspection processes to ensure that every piece meets the required specifications. This attention to quality has enabled many manufacturers to obtain certifications such as ISO 9001, which is essential for competing globally.

The collaboration between Chinese sand casting manufacturers and international clients has also fostered a culture of continuous improvement. By understanding the specific needs and standards of different markets, factories are constantly refining their processes and technologies to maintain a competitive edge.

Conclusion

China's sand casting factories are at the forefront of a dynamic manufacturing landscape, characterized by innovation and adaptability. With a focus on technology, sustainability, and quality control, these factories are not only meeting local demands but are also becoming significant players in the global market. As the industry continues to evolve, China’s sand casting sector is well-positioned to navigate the challenges of the future, ensuring it remains a vital component of the manufacturing world.

-

High-Precision Colloidal Silica Casting Solutions Custom & ODM

NewsMay.20,2025

-

High-Efficiency Cast Silico Aluminum Gas Boiler ODM & Custom Solutions

NewsMay.20,2025

-

Steel Reinforced Concrete Pipe Bottom Ring Moulds Buy Custom Solutions

NewsMay.19,2025

-

Original Concrete Pipe Mold Bottom Ring & Pallet Chinese Factory Direct Sale

NewsMay.19,2025

-

Custom Room Heating Heat Exchangers Energy-Efficient Solutions

NewsMay.18,2025

-

Precision Milling Body Casting Solutions Custom & ODM Options

NewsMay.18,2025