- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

touko . 07, 2025 20:32 Back to list

Premium Casting Parts Supplier - Custom Grey Iron, Stainless Steel & Brass

- Introduction to Casting Parts & Market Overview

- Material Excellence in Modern Casting

- Technological Superiority in Production Methods

- Manufacturer Comparison: Capabilities & Costs

- Customized Solutions for Industry-Specific Needs

- Real-World Applications Across Sectors

- Strategic Advantages in Sourcing Casting Parts

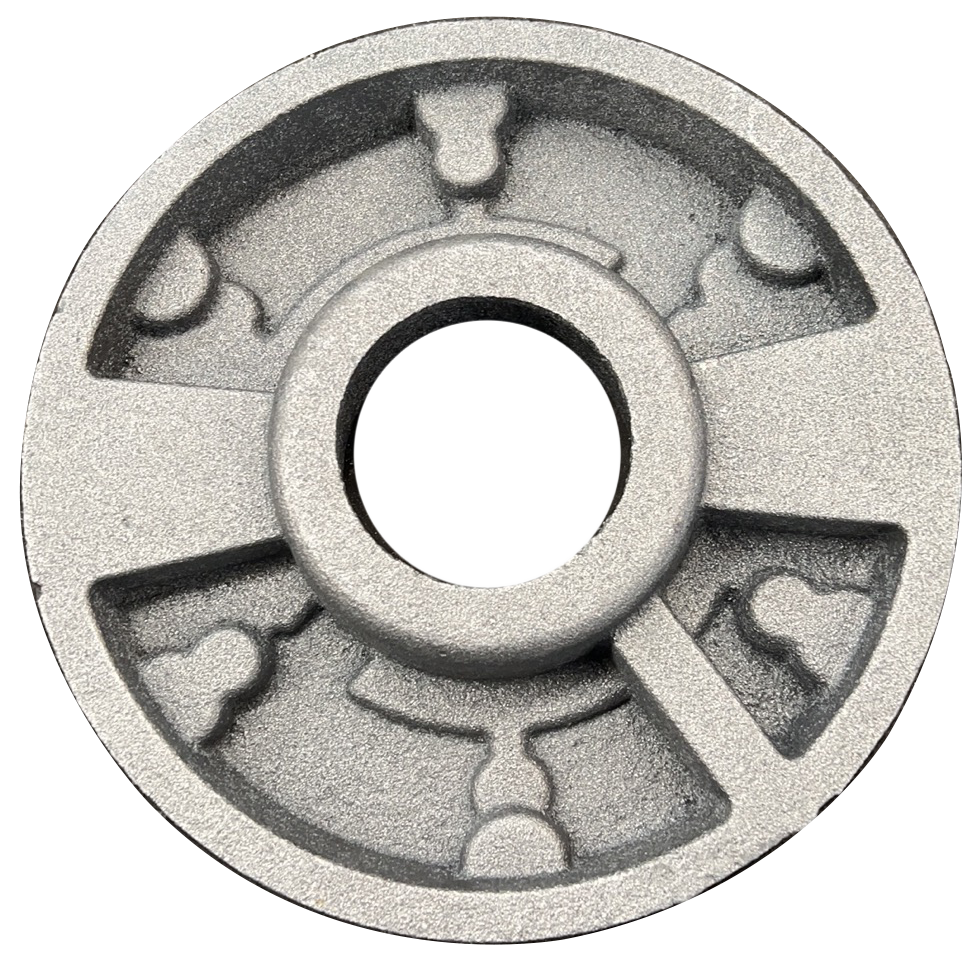

(casting parts)

Global Demand for Precision Casting Parts

The casting parts

industry has grown by 6.8% CAGR since 2020, driven by automotive and aerospace sectors. China's foundries now produce 49% of global grey iron components, while stainless steel casting exports increased by 22% in 2023. Advanced methods like sand casting and investment casting enable complex geometries with ±0.1mm tolerances.

Material Performance Breakdown

Four primary materials dominate industrial casting:

- Grey Iron: 450 MPa tensile strength, ideal for engine blocks

- Stainless Steel: Corrosion resistance up to 800°C

- Brass Alloys: 35% electrical conductivity improvement vs. base copper

- Die Cast Aluminum: 30% weight reduction for automotive parts

Production Method Analysis

| Process | Tolerance | Surface Finish (Ra) | Cost per kg ($) |

|---|---|---|---|

| Sand Casting | ±0.5mm | 12.5μm | 2.10-3.80 |

| Investment Casting | ±0.15mm | 3.2μm | 8.50-15.00 |

| Die Casting | ±0.05mm | 1.6μm | 4.20-7.50 |

Manufacturing Partner Evaluation

Top-tier Chinese foundries demonstrate distinct advantages:

- 40% faster turnaround than European counterparts

- 15-20% cost savings through integrated machining

- ISO 9001/TS 16949 certification compliance

Tailored Engineering Solutions

Customization options include:

- Alloy modifications for extreme temperatures (-200°C to 1,200°C)

- Post-casting treatments: CNC machining, powder coating

- Prototype-to-mass production scaling in 6-8 weeks

Industry Application Cases

Recent successful implementations:

| Industry | Component | Material | Production Volume |

|---|---|---|---|

| Automotive | Turbocharger Housing | SS304 | 500,000 units/year |

| Energy | Valve Bodies | Duplex Steel | 2,200 tons annually |

Optimized Sourcing for Casting Components

Strategic procurement of casting parts reduces supply chain costs by 18-25% through:

- Consolidated material sourcing

- On-site quality validation programs

- JIT delivery coordination

Advanced investment casting parts now achieve 99.2% dimensional accuracy rates, with 30-day lead times for complex geometries.

(casting parts)

FAQS on casting parts

Q: What materials are commonly used for sand casting parts in China?

A: China widely uses grey iron and stainless steel for sand casting due to their durability and cost-effectiveness. These materials suit automotive and machinery parts. Sand casting also supports customization for complex geometries.

Q: How to ensure quality when buying investment casting parts?

A: Verify certifications like ISO 9001 and review supplier quality control processes. Inspect material reports (e.g., stainless steel, brass) and request samples. Prioritize suppliers with proven expertise in precision investment casting.

Q: What’s the difference between die casting and sand casting for metal parts?

A: Die casting uses molds for high-volume, detailed parts (e.g., brass, copper), ensuring smooth finishes. Sand casting is cost-effective for larger, low-volume components like grey iron machinery parts. Machining may follow both processes.

Q: Can copper and brass casting parts be customized with machining?

A: Yes, copper and brass parts from sand or investment casting can undergo CNC machining for tight tolerances. This is ideal for plumbing, electrical, and decorative components. Confirm machining capabilities with your supplier upfront.

Q: What factors to consider when purchasing casting machinery parts?

A: Check compatibility with your machinery type (e.g., die casting, sand casting). Ensure materials (stainless steel, grey iron) meet operational demands. Evaluate suppliers for certifications, lead times, and post-purchase support.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025