- afrikkalainen

- albanialainen

- amhara

- arabialainen

- armenialainen

- Azerbaidžani

- baski

- valkovenäläinen

- bengali

- bosnialainen

- bulgarialainen

- katalaani

- Cebuano

- Kiina

- Kiina (Taiwan)

- Korsikalainen

- kroatialainen

- Tšekki

- Tanskan kieli

- Hollannin kieli

- Englanti

- esperanto

- Virolainen

- Suomalainen

- Ranskan kieli

- friisi

- Galicialainen

- Georgian

- Saksan kieli

- kreikkalainen

- gudžarati

- Haitin kreoli

- hausa

- havaijilainen

- heprealainen

- Ei

- Miao

- Unkarin kieli

- islantilainen

- igbo

- Indonesialainen

- irlantilainen

- italialainen

- japanilainen

- jaavalainen

- kannada

- kazakki

- khmerit

- Ruanda

- Korealainen

- kurdi

- Kirgisia

- Työvoimaa

- Latina

- Latvialainen

- liettualainen

- luxemburgilainen

- makedonialainen

- Malgashi

- malaiji

- malajalami

- maltalainen

- maori

- marathi

- mongolialainen

- Myanmar

- Nepali

- Norjan kieli

- Norjan kieli

- Oksitaani

- pashto

- persialainen

- Kiillottaa

- Portugalin kieli

- Punjabi

- romanialainen

- Venäjän kieli

- samoalainen

- Skotlannin gaeli

- serbia

- Englanti

- Shona

- Sindhi

- sinhala

- Slovakian

- slovenialainen

- somali

- Espanja

- sundalainen

- swahili

- Ruotsin kieli

- Tagalog

- tadžiki

- tamili

- tatari

- telugu

- thaimaalainen

- turkkilainen

- Turkmenistan

- ukrainalainen

- urdu

- uiguuri

- uzbekki

- vietnam

- Walesin

- auta

- jiddish

- joruba

- zulu

kesä . 09, 2025 15:52 Takaisin listalle

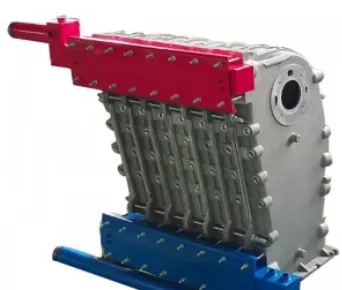

Heat Exchanger Selection for Boiler Systems

Selecting the right heat exchanger is critical for optimizing boiler performance, energy efficiency, and system longevity. With advancements in heating technology, professionals must consider multiple factors when choosing between different heat exchanger types, especially when integrating them with modern systems like vähätyppinen lauhduttava kaasukattila. One of the most innovative developments in this field is the cast silicon aluminum heat exchanger for hot water boiler, which offers superior thermal conductivity and corrosion resistance. Additionally, manufacturers are now producing complete gas fired boiler made from cast silico aluminum heat exchanger units that combine efficiency with durability.

This comprehensive guide explores key selection criteria while highlighting how these advanced heat exchanger technologies are revolutionizing commercial and residential heating systems.

Understanding Heat Exchanger Performance in Low Nitrogen Condensing Gas Fired Boiler

Low nitrogen condensing gas fired boiler represents the pinnacle of energy-efficient heating technology, but their performance heavily depends on the heat exchanger's capabilities. These boilers require heat exchanger that can handle condensing flue gases while maintaining high thermal efficiency.

Key selection criteria include:

Corrosion resistance - Must withstand acidic condensate formation

Thermal conductivity - Needs to maximize heat transfer from flue gases

Pressure tolerance - Should maintain structural integrity under operating pressures

Compact design - Space-saving configurations for modern installations

The cast silicon aluminum heat exchanger for hot water boiler has emerged as an ideal solution for these applications due to its excellent corrosion resistance and heat transfer properties. Unlike traditional stainless steel, aluminum alloys maintain performance while reducing weight and cost.

Advantages of Cast Silicon Aluminum Heat Exchangers for Hot Water Boiler

The cast silicon aluminum heat exchanger for hot water boiler offers several distinct advantages that make it preferable for many modern heating applications:

Excellent corrosion resistance - Naturally forms protective oxide layer

Cost-effective manufacturing - Casting process allows complex geometries

Long service life - Typically lasts 5-10 years longer than steel counterparts

When integrated into a complete gas fired boiler made from cast silico aluminum heat exchanger, these benefits translate to higher system efficiency, lower maintenance costs, and reduced energy consumption. The material's natural resistance to scale formation also minimizes performance degradation over time.

Gas Fired Boiler Made From Cast Silico Aluminum Heat Exchanger: A Complete Solution

Modern gas fired boiler made from cast silico aluminum heat exchanger systems represent a significant advancement in heating technology. These complete packages combine the efficiency of condensing technology with the durability of advanced materials.

Key features to look for:

Integrated condensing technology - Maximizes heat recovery from flue gases

Modulating burners - Matches output to demand for optimal efficiency

Smart controls - Allows precise temperature management

Compact footprint - Ideal for space-constrained installations

Low NOx emissions - Meets stringent environmental regulations

These systems are particularly effective when paired with vähätyppinen lauhduttava kaasukattila technology, creating a solution that delivers both environmental benefits and operational cost savings. The aluminum construction also makes these units significantly lighter than traditional cast iron boilers, simplifying installation and reducing structural support requirements.

Low nitrogen condensing gas fired boiler Applications

For vähätyppinen lauhduttava kaasukattila applications, the cast silicon aluminum option often provides the best balance of performance and longevity, especially in systems where weight and efficiency are primary concerns.

FAQs about Heat Exchanger Selection for Modern Boiler Systems

What makes cast silicon aluminum heat exchanger for hot water boiler better for condensing boilers?

The cast silicon aluminum heat exchanger for hot water boiler excels in condensing applications because it resists corrosion from acidic condensate while providing superior heat transfer. Its lightweight nature also reduces overall system weight compared to traditional materials.

How does a gas fired boiler made from cast silico aluminum heat exchanger improve efficiency?

These boilers combine the condensing principle with excellent thermal conductivity of aluminum, allowing more heat to be extracted from combustion gases. The material's resistance to scaling also maintains efficiency over time better than other metals.

Are low nitrogen condensing gas fired boiler compatible with all heat exchanger types?

While they can work with various materials, vähätyppinen lauhduttava kaasukattila achieves best performance with corrosion-resistant options like stainless steel or cast silicon aluminum due to the acidic nature of condensate.

What maintenance does a cast silicon aluminum heat exchanger require?

These heat exchanger needs minimal maintenance thanks to their corrosion resistance. Annual inspections and occasional cleaning (depending on water quality) are typically sufficient to maintain peak performance.

How long does a gas fired boiler with cast silico aluminum heat exchanger typically last?

With proper maintenance, these systems often last 20-25 years, significantly longer than traditional boiler with steel heat exchanger. The aluminum's corrosion resistance is the primary factor in this extended lifespan.

Selecting the right heat exchanger requires careful consideration of materials, application requirements, and system compatibility. The emergence of cast silicon aluminum heat exchanger for hot water boiler technology has provided an excellent solution for modern vähätyppinen lauhduttava kaasukattila systems, offering superior efficiency and longevity. Complete gas fired boiler made from cast silico aluminum heat exchanger packages now deliver unprecedented performance while meeting stringent environmental standards.

By understanding these advanced technologies and their benefits, engineers and facility managers can make informed decisions that optimize system performance, reduce operating costs, and extend equipment lifecycles. The future of heating technology clearly lies in these innovative material applications that push the boundaries of efficiency and durability.

-

The Ultimate Choice for Optimal Thermal Exchange: Hex Heat Exchangers

UutisetJun.24,2025

-

Hydronic Gas Boiler: The Efficient Heating Solution For Your Needs

UutisetJun.24,2025

-

Discover the Efficiency of Mini Boiler Gas

UutisetJun.24,2025

-

Concrete Pipe Mold Pallet Solutions

UutisetJun.24,2025

-

Unveiling the Benefits of Light Pallet Mould

UutisetJun.24,2025

-

Discover the Benefits of Ductile Cast Iron Pipe Mold Pallet

UutisetJun.24,2025