- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Sep . 29, 2024 03:59 Back to list

Purchase Steel Reinforced Concrete Pipe Mold Pallets for Optimal Construction Solutions

The Importance of Buying Steel Reinforced Concrete Pipe Molds and Pallets

In the construction and infrastructure industry, the use of durable and high-quality materials is essential for ensuring the longevity and strength of structures. Among these materials, steel reinforced concrete is favored for its exceptional properties. To manufacture steel reinforced concrete pipes, one critical component is the mold used to form them. This article discusses the importance of purchasing steel reinforced concrete pipe molds and pallets, the advantages they bring, and the considerations to keep in mind when making a purchase.

Understanding Steel Reinforced Concrete Pipes

Steel reinforced concrete pipes (SRCP) are designed to handle high tensile and compressive stresses, making them ideal for various applications, including drainage systems, sewerage systems, and more. The incorporation of steel reinforcement enhances the strength and ductility of concrete, allowing these pipes to withstand significant loads and adverse environmental conditions.

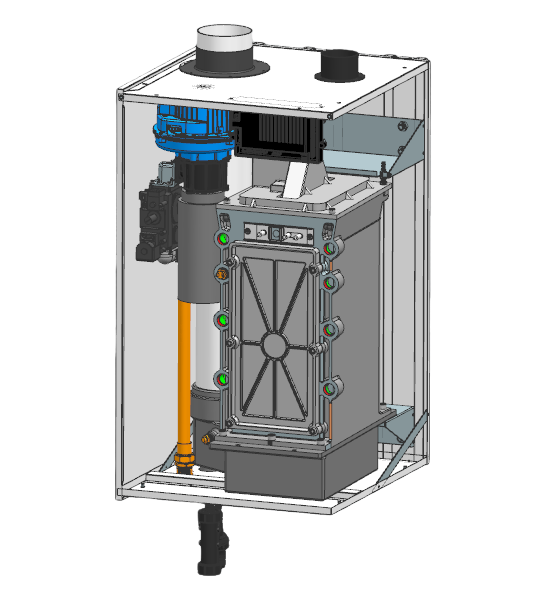

The manufacturing process of these pipes involves the use of specialized molds that determine the shape, dimensions, and surface finish of the final product. Therefore, investing in high-quality molds is paramount to achieving the desired performance and durability of the concrete pipes.

The Role of Molds in Pipe Production

Molds for SRCP production are typically made from tough materials that can withstand the pressure and wear from the concrete. They are engineered to achieve precise dimensions and interior finishes, ensuring that the pipes produced meet industry standards and specifications. The right mold will also ease the demolding process, thereby improving production efficiency and minimizing maintenance costs associated with mold wear.

In addition to molds, pallets are essential for the transportation and handling of concrete pipes during the curing process. Pallets provide a stable base for the molds, ensuring that they remain level and securely positioned as the concrete sets. Proper handling of both molds and pallets is crucial for maintaining the quality and integrity of the concrete pipes.

Advantages of Purchasing High-Quality Molds and Pallets

1. Durability Quality molds and pallets are designed to endure the harsh conditions of concrete production, leading to less wear and longer service life.

3. Efficiency Well-designed molds facilitate faster production cycles, while sturdy pallets ensure safe transport and handling, ultimately leading to higher productivity.

buy steel reinforced concrete pipe mold pallet

4. Cost-Effectiveness Although the initial investment in high-quality molds and pallets may be higher, the long-term savings from reduced maintenance, fewer production errors, and increased output can far outweigh these costs.

5. Compliance with Standards High-quality molds often comply with international manufacturing standards, ensuring that the produced concrete pipes meet necessary regulations and quality benchmarks.

Considerations When Buying

When selecting molds and pallets for steel reinforced concrete pipes, several factors should be considered

- Material Quality Ensure that molds and pallets are made from high-grade materials that can withstand the rigors of the production process.

- Supplier Reputation Choose suppliers with a proven track record in manufacturing durable and efficient molds.

- Customization Options Consider whether the supplier offers custom molds tailored to specific project requirements.

- Cost While price is an important factor, it is essential to balance cost with quality to ensure that you get the best value for your investment.

- After-Sales Support Opt for suppliers who provide substantial after-sales support, including maintenance tips, service options, and replacement policies.

Conclusion

In conclusion, investing in high-quality steel reinforced concrete pipe molds and pallets is crucial for maintaining the efficiency, durability, and cost-effectiveness of concrete pipe production. By making informed purchasing decisions, manufacturers can ensure that they produce high-quality pipes that meet industry standards and serve their intended purpose effectively. As you consider this important aspect of your production process, keep in mind the long-term benefits that quality molds and pallets can bring to your operations.

-

Premium Custom & ODM Vehicle Parts Bulk Order Deals

NewsMay.17,2025

-

Custom Commercial Hot Water Heat Exchangers High-Efficiency Solutions

NewsMay.17,2025

-

Custom Fibre Reinforced Concrete Pipe Bottom Ring Moulds – Buy Durable Solutions

NewsMay.17,2025

-

Steel Reinforced Concrete Pipe Bottom Ring Molds High-Quality & Custom

NewsMay.16,2025

-

Low NOx Condensing Gas Boilers for Domestic Hot Water ODM & Custom

NewsMay.16,2025

-

Buy Cast Silicon Aluminum Hot Water Heat Exchangers Efficient & Durable

NewsMay.15,2025