- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Déc . 12, 2024 12:32 Back to list

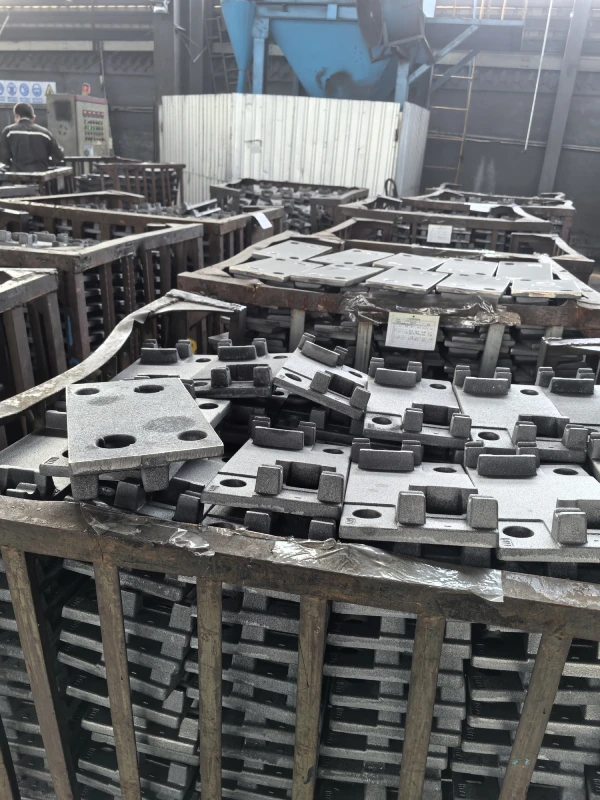

copper sand casting factory

The Significance of Copper Sand Casting in Modern Manufacturing

Copper sand casting is a pivotal process in the manufacturing industry, known for its ability to produce complex and durable components with excellent dimensional accuracy. This technique involves forming a mold from sand, which is then filled with molten copper to create a wide range of products. In this article, we will explore the ins and outs of copper sand casting, its advantages, applications, and the role of factories in this manufacturing method.

Understanding Copper Sand Casting

Copper sand casting is a form of metal casting that combines the ancient art of sand casting with the unique properties of copper alloys. The process begins with the creation of a mold made from a mixture of sand and a binder, which can withstand high temperatures. Once the mold is prepared, molten copper is poured into it, filling the cavity. After the copper cools and solidifies, the sand mold is broken away, revealing the finished part. This technique is favored for its adaptability, enabling manufacturers to create intricate designs that may be difficult or impossible to achieve through other methods.

Advantages of Copper Sand Casting

1. Versatility Copper sand casting is suitable for manufacturing a wide array of products, from small components to large industrial parts. The ability to use various types of copper alloys allows for customization based on the mechanical and thermal properties required for specific applications.

2. Cost-Effectiveness In comparison to other casting methods like investment casting, sand casting can be more economical, especially for smaller production runs. The materials required for sand molds are relatively inexpensive, making it an attractive option for many manufacturers.

3. Dimensional Accuracy This process can achieve high levels of precision. With proper mold design and control over pour temperatures, manufacturers can produce parts that meet stringent tolerances and specifications.

copper sand casting factory

4. High Thermal and Electrical Conductivity Copper is known for its excellent thermal and electrical properties, making it an ideal choice for applications ranging from electrical components to heat exchangers. Sand casting captures these properties, producing parts that excel in demanding environments.

Applications of Copper Sand Casting

The applications of copper sand casting are vast and varied. In the automotive industry, this technique is employed to create parts such as engine components, heat sinks, and connectors, all of which require exceptional durability and thermal conductivity. In the electronics realm, copper castings are utilized for electrical connectors, circuit boards, and various components that demand reliable conductivity. Moreover, in the plumbing and HVAC industries, cast copper fittings and valves are ubiquitous, showcasing the versatility of this manufacturing method.

The Role of Copper Sand Casting Factories

Copper sand casting factories play a crucial role in the manufacturing landscape. These facilities are equipped with specialized machinery and skilled labor to ensure that the casting processes are carried out efficiently and effectively. Innovation in factory technology, such as automation and computer-aided design (CAD), has enhanced the capabilities of these facilities, allowing for faster production times and higher precision.

Moreover, many factories are incorporating sustainable practices in their operations. This includes recycling foundry sand and reducing energy consumption during the casting process. By adopting environmentally friendly methods, these factories not only comply with regulations but also contribute to the global push for sustainability.

Conclusion

Copper sand casting is a vital manufacturing method that combines historical techniques with modern technology. Its ability to produce intricate, high-quality components at a reasonable cost makes it indispensable across various industries. The ongoing advancements in casting technology and the commitment of factories to sustainability further highlight the importance of copper sand casting in contemporary manufacturing. As industries continue to evolve, the demand for copper castings will only grow, solidifying its place as a cornerstone of material processing and engineering innovation. Whether in automotive applications, electronics, or construction, copper sand casting will remain a powerhouse of modern manufacturing for years to come.

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025

-

Durable Cast Iron Water Main Pipe | Buy Ductile Pipe

NewsAug.06,2025