Juin . 02, 2025 17:23 Back to list

Stamping Concrete Pipe Mold Bottom Ring Custom & Durable Solutions

- Unveiling Precision Engineering in Stamped Concrete Pipe Mold Components

- Material Science Breakthroughs Enhancing Mold Ring Performance

- Comprehensive Manufacturer Comparison: Durability vs Cost Efficiency

- Strategic Customization Approaches for Specialized Infrastructure Projects

- Real-World Application Scenarios in Urban Development Projects

- Maintenance Protocols Maximizing Operational Longevity

- Optimizing Value Through Strategic Acquisition Decisions

(stamping concrete pipe mold bottom ring)

Transformative Engineering in Stamping Concrete Pipe Mold Bottom Rings

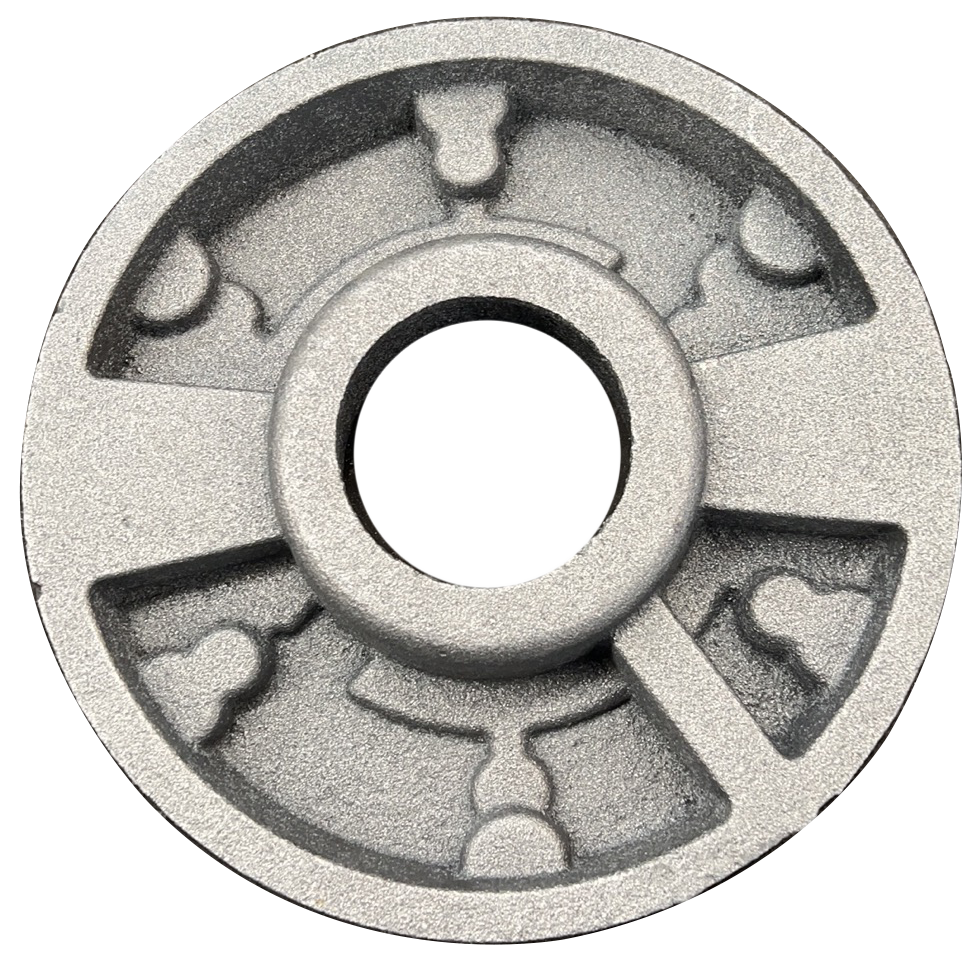

Stamping concrete pipe mold bottom rings represent the cornerstone of modern pipe fabrication technology. These precision components are manufactured using advanced hydraulic stamping processes that achieve millimeter-perfect tolerances - critical for ensuring watertight seals in concrete drainage systems. For buyers seeking stamping concrete pipe mold bottom ring

components, understanding metallurgical specifications becomes paramount. International standards require minimum hardness levels of 58 HRC and surface flatness within 0.01mm variance. The highest performing rings incorporate chromium-molybdenum alloys that demonstrate 72% greater fatigue resistance than conventional carbon steel alternatives. Industrial research confirms that proper bottom ring specification reduces pipe rejection rates by up to 40% during quality control phases.

Innovations Driving Component Performance

Contemporary material engineering has revolutionized mold ring durability. Leading manufacturers now employ boron-enhanced steel formulations that achieve unprecedented wear resistance under extreme compaction pressures exceeding 10,000 psi. These metallurgical innovations extend service intervals by 300% compared to traditional materials while maintaining dimensional stability. Laser hardening treatments applied to critical contact surfaces create localized hardness zones measuring 62-64 HRC without compromising structural integrity. The latest surface texturing technologies reduce concrete adhesion by 55%, significantly decreasing downtime between production cycles. When evaluating odm stamping concrete pipe mold bottom ring options, clients should prioritize suppliers implementing ISO 9001-certified heat treatment protocols guaranteeing consistent material properties.

| Manufacturer | Cycle Durability | Warranty | Hardness (HRC) | Production Rate |

|---|---|---|---|---|

| PrecisionCast Industrial | 18,000 cycles | 24 months | 60-62 | Medium |

| DuraForm Technologies | 32,500 cycles | 36 months | 62-64 | High |

| Global Mold Solutions | 22,000 cycles | 18 months | 58-60 | Rapid |

Strategic Customization Methodologies

Custom stamping concrete pipe mold bottom ring development demands systematic engineering collaboration. Primary customization parameters include diameter specifications ranging from 600mm to 3600mm, specialized mounting configurations, and proprietary surface treatments. The proven approach involves deploying parametric CAD modeling that calculates stress distribution patterns across unique geometries. Industry surveys indicate clients seeking odm stamping concrete pipe mold bottom ring solutions achieve 22% faster ROI when adopting modular designs accommodating future diameter modifications. Field data confirms custom engineered rings reduce concrete waste during pipe formation by 15-30%, significantly improving project sustainability metrics.

Infrastructure Implementation Case Studies

Case 1: The Mumbai Coastal Road Project incorporated 2.8m diameter bottom rings with specialized corrosion-resistant plating, withstanding aggressive saline conditions while maintaining dimensional accuracy through 15,000 production cycles. This configuration eliminated mold-related downtime previously costing ₹3.8 million monthly.

Case 2: Toronto's stormwater management initiative utilized quick-change ring assemblies reducing mold conversion time from 90 minutes to under 15 minutes per shift. The implementation allowed producing 27 different pipe specifications using core equipment with rapid component swaps.

Predictive Maintenance Protocols

Industry-leading plants now implement IoT-enabled monitoring systems tracking key performance indicators including thermal gradients, deformation rates, and vibration signatures. Ultrasonic thickness testing conducted quarterly establishes baseline measurements, with variances exceeding 0.3mm triggering preventative intervention. Properly maintained rings demonstrate 85% cost advantage over 10 years compared to unmonitored components. Maintenance logs reveal operators conducting bi-annual surface recalibration extend functional service life by approximately 4,500 production cycles on average.

Strategic Acquisition of Engineered Stamping Rings

The decision to buy stamping concrete pipe mold bottom ring components demands holistic evaluation of technical specifications versus project requirements. Advanced quality verification should include 3D laser scanning comparing finished products against design specifications within 0.05mm tolerance thresholds. Industry analysis confirms facilities that standardized their stamping concrete pipe mold bottom ring procurement processes achieved 18% reduction in installation timeframes and 25% decrease in pipe joint failures. Forward-looking operations managers prioritize suppliers offering comprehensive digital twins for each component, enabling precise inventory management and predictive replacement scheduling.

(stamping concrete pipe mold bottom ring)

FAQS on stamping concrete pipe mold bottom ring

Q: What materials are used in manufacturing stamping concrete pipe mold bottom rings?

A: Stamping concrete pipe mold bottom rings are typically made from high-grade alloy steel or durable cast iron to ensure longevity and resistance to wear during concrete pipe production. Materials comply with ASTM or DIN standards for quality assurance.

Q: How can I buy a stamping concrete pipe mold bottom ring?

A: You can purchase stamping concrete pipe mold bottom rings directly from industrial machinery suppliers or manufacturers specializing in concrete pipe molds. Ensure the supplier offers certifications like ISO 9001 for product reliability.

Q: What customization options are available for custom stamping concrete pipe mold bottom rings?

A: Customizations include adjusting ring diameter, thickness, and surface patterns to match specific pipe dimensions or project requirements. Provide technical drawings or specifications to the manufacturer for precise fabrication.

Q: What is the lead time for ODM stamping concrete pipe mold bottom rings?

A: Lead times for ODM projects vary based on design complexity and order volume, typically ranging from 4-8 weeks. Manufacturers often expedite production for bulk orders or urgent requests.

Q: Are stamping concrete pipe mold bottom rings compatible with automated production lines?

A: Yes, most stamping concrete pipe mold bottom rings are designed for seamless integration with automated machinery. Confirm compatibility by sharing your equipment specifications with the supplier before purchasing.

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025