- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Iuch . 29, 2025 19:20 Back to list

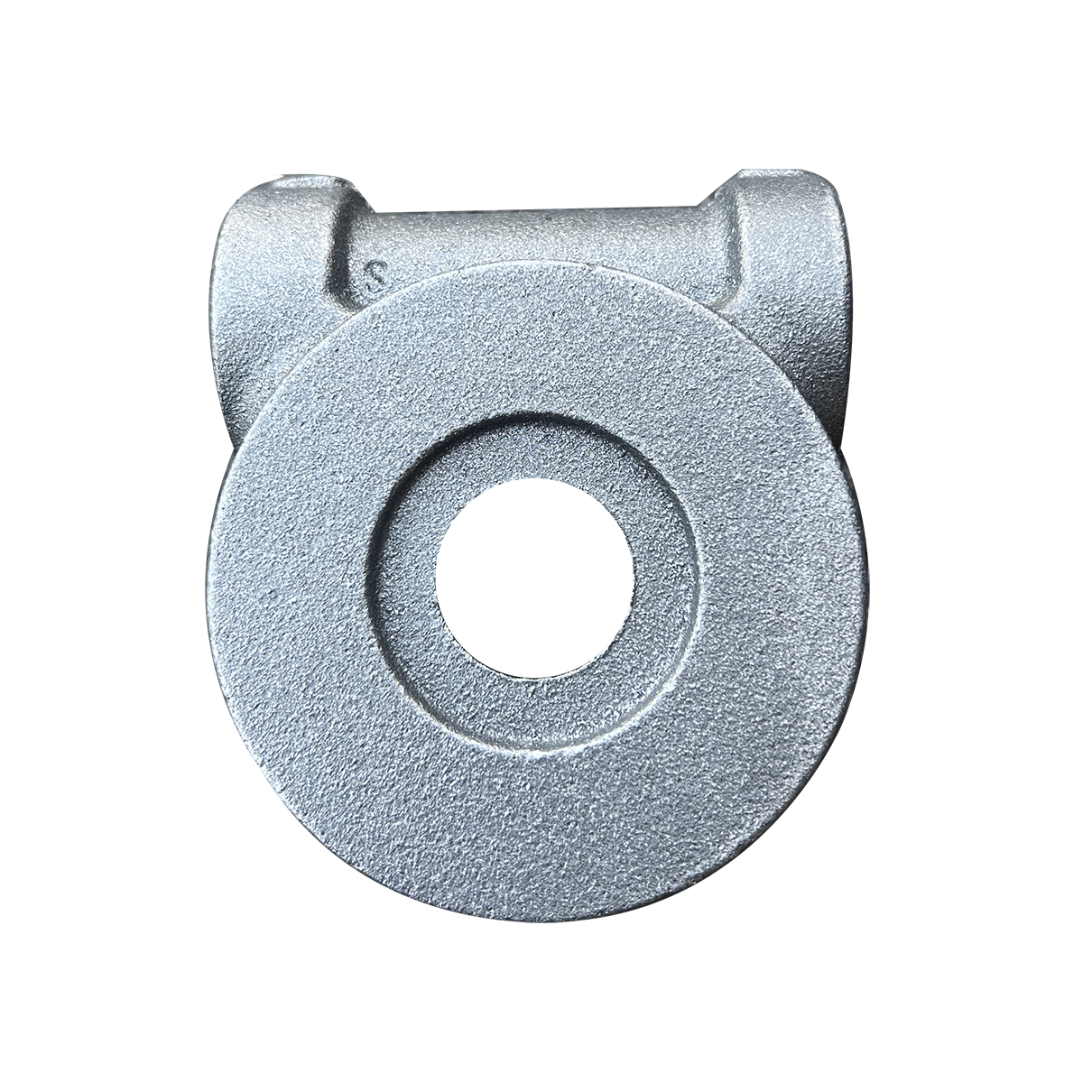

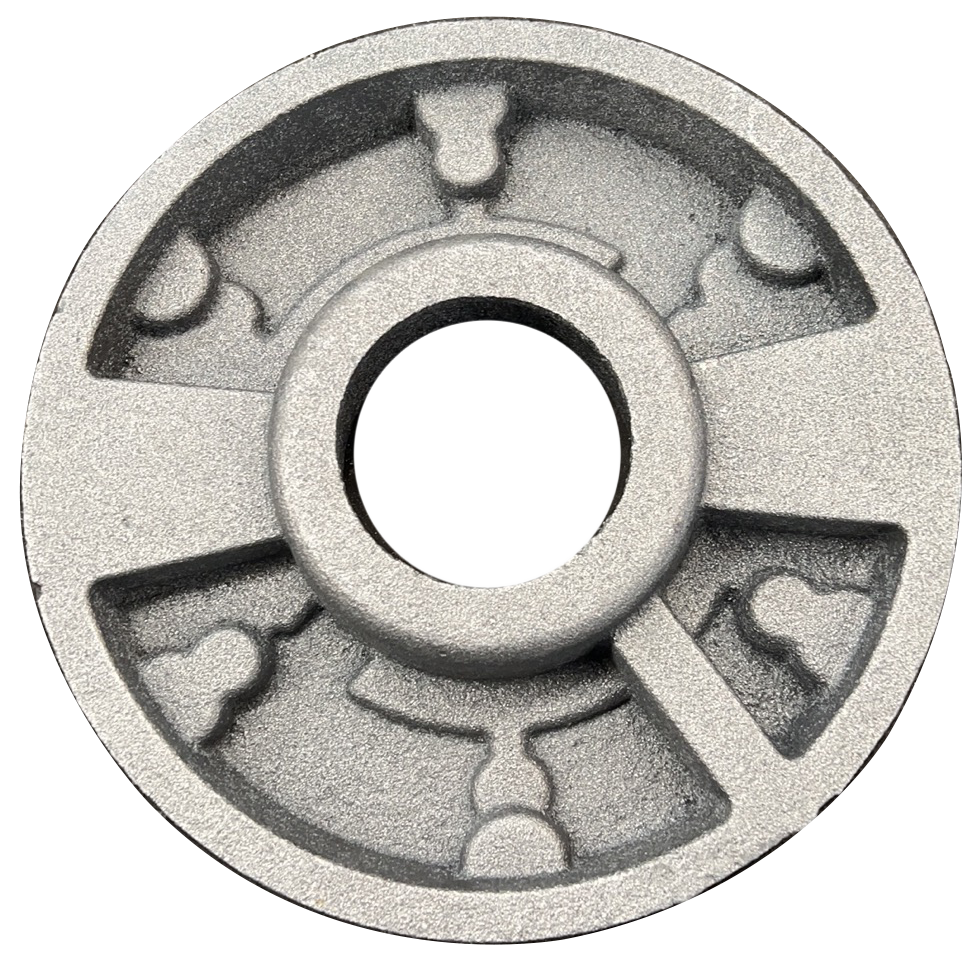

Ductile Iron Supplier Service from China Source Factory & Powerful Seller

Unlock the power of Ductile Iron Supplier Service from China’s original supplier for robust performance, advanced manufacturing, and technical excellence in cast solutions for various industries. Explore Product Details

Industry Trends in Ductile Iron Supplier Service (2024 Analysis)

- Surge in Global Demand: The global ductile iron market is projected to reach USD 18.6 billion by 2027, at a CAGR of 4.2% (Source: MarketsandMarkets).

- Technological Innovations: Automation, CNC precision machining, and environmental-friendly melting processes are dominating supplier service strategies.

- Sustainable Solutions: Leading Ductile Iron Supplier Service companies in China deploy low-emission furnaces and 100% material reuse in their Source Factory workflow.

- Certification Standards: Strict adoption of ISO 9001:2015 and ANSI/AWWA C115 ensures quality & reliability for waterworks, petrochemical, and metallurgy applications.

Ductile Iron Supplier Service - Main Technical Parameters

| Parameter | Specification | Industry Standard | Typical Value |

|---|---|---|---|

| Material | Ductile Iron (ASTM A536 65-45-12, EN-GJS-500-7, QT500-7) | ISO 1083 | Ferritic/Perlitic Matrix (~90% carbon-free ferrite) |

| Tensile Strength | 420–700 MPa | GB/T 1348-2019 | Min. 550 MPa |

| Yield Strength | ≥320 MPa | ISO 1083 | 370 MPa |

| Elongation | ≥7% | ISO 1083 | 10–15% |

| Hardness | 170–230 HB | ISO 6506 | 185–215 HB |

| Wall Thickness | 3 mm – 60 mm | AWWA C151 | Customizable |

| Coating | Zinc, Epoxy, Bitumen | ISO 2531, EN545 | ≥70μm epoxy (internal), ≥130g/m² zinc (external) |

| Lifespan | 50+ Years | ISO 2531:2022 | 55–70 Years (field data) |

| Main Applications | Pipelines, Valves, Fittings, Pump Bodies | ISO/EN/ASTM | Water, Oil & Gas, Chemical, Mining |

Manufacturing Process Flow: Ductile Iron Supplier Service

- Raw Material Selection → Strictly filtered iron ore & alloy, traceability certified.

- Melting & Spheroidization → Induction furnace, Mg addition converts graphite to spheroidal form.

- Quality Inspection - Furnace Sample Test → Spectrometry, tensile tests per ISO 1083.

- Molding & Casting → Green sand/Resin sand patterns for precision; design fits AWWA/EN/DIN specs.

- CNC Machining → Achieve high dimensional tolerance (±0.03mm), surface finish Ra < 1.6μm.

- Coating & Anti-Corrosion Treatment → Epoxy/zinc/bitumen coats using auto-spray lines (ISO 8179-1 compliant).

- Final Inspection & Certification → Hydrostatic, X-ray, ultrasonic, and third-party audits (SGS/TUV).

- Packing & Global Dispatch → Wooden crates, 100% seaworthy, full traceable logistics.

Product Comparison: Ductile Iron Supplier Service vs Others

| Features | Ductile Iron Supplier Service (China Original Supplier) | OEM Regional Supplier | Other Imports |

|---|---|---|---|

| Source Factory | Direct (Zero Intermediary) | Often Indirect | Multi-layer Agents |

| Production Capacity | 100,000+ tons/year | 20,000–40,000 tons/year | Unstable |

| Certification | ISO 9001, TUV, SGS | Partial ISO Only | Unknown/None |

| Machining Precision | ±0.03mm (CNC) | ±0.06mm | >±0.10mm |

| Cost Effectiveness | Best | Moderate | High |

| Delivery Lead Time | 15–25 days | 28–45 days | 35–70 days |

| Custom Solutions | Yes (All Specs) | Limited | Difficult |

Customized Solutions with Ductile Iron Supplier Service

- End-to-End Service: From casting design, rapid prototyping, mold production, to massive-multi volume supply in Source Factory scale.

- Material Grade Selection: QT400-18, QT500-7, ASTM A536 and more, tailored to yield strength, impact, welding needs.

- Dimension Flexibility: Max outer diameter up to 2m, minimum wall thickness 3mm, complex geometry support.

- Surface Engineering: Zinc-rich, fusible epoxy, anti-UV & high-alkali bitumen, for environments from mining, water to HVAC.

- Quality Assurance: Full batch traceability, 5-stage in-process inspections, dedicated in-house lab accredited to ISO 17025.

- Rapid Prototyping: 3D-printed sand molds & CNC sample pieces for expedited project timeline (as short as 14 days).

- Powerful Seller: Global shipping to 32+ countries, multilingual after-sales team, dedicated OEM/ODM engineers.

Application Cases: Ductile Iron Supplier Service in Action

- Water Main Pipeline Retrofit – Spain, 2023: 23KM ductile iron pipeline (Φ600mm, EN-GJS-500-7, internal fusion bonded epoxy), installed over 4 months, 99.98% leak-free on hydrotest, projected lifespan 60 years.

- Petrochemical Valve Supplier – Middle East, 2022: Ductile iron valve bodies (ASTM A536 60-42-10), 8000+ units, withstand 18 bar operation, coated with ISO 8179 compliant bitumen for anti-corrosion, delivery in 19 days.

- Mining Slurry Pipe Fittings – Chile, 2021-2023: Custom spheroidal graphite iron castings, modular quick-joint design (patented), anti-abrasion enamel lining; reduced slurry leakage risk by 83% vs previous solution.

- Municipal Stormwater Project – Australia, 2024: Supplied over 12,000 ductile iron manhole covers & grates (QT450-10, EN124), delivered on-site with 96% ahead-of-schedule completion.

-

Reference Test Data:

- ISO 2531 test pass rate: 100% (3rd-party lab validated)

- Salt spray test (750hrs): No pitting or delamination

- Compressive strength in field: 185–232 MPa (avg.)

Industry Authority: Certifications, Partnerships & Trust

-

Certifications:

ISO 9001:2015, ISO 14001:2016, OHSAS 18001, TUV, SGS

(Regular full audits to guarantee consistency & reliability for Ductile Iron Supplier Service products.) - Cooperation Partners: Veolia Water, SUEZ, Sinopec, PetroChina, Thames Water, Xylem, Vinci Construction, and 1000+ municipal utilities worldwide.

- Service Years: Over 36 years of continuous operation; 3500+ major projects supplied since 1988.

- Authoritative Standards: Compliance with ISO, EN, ASTM, ANSI, BS, AWWA in pipeline, valves, and foundry products.

- Third-party Data Reference: Cited by AALEP and referenced in Journal of Materials Processing Technology (Elsevier).

Ductile Iron Supplier Service – Expert FAQ

- 1. What alloy composition is standard for ductile iron in supplier services?

- Typical ductile iron alloys use 3.2–3.8% carbon, 2.0–2.7% silicon, ≤0.05% magnesium for spheroidization, and trace manganese. This creates a ferritic-perlitic matrix optimized for strength and ductility (see ISO 1083, ASTM A536).

- 2. What is the minimum and maximum wall thickness for customized castings?

- Most Ductile Iron Supplier Service source factories offer thicknesses from 3mm (small valve bodies) to 60mm (large flanges/pump housings), with custom CNC finishing to ±0.03mm.

- 3. Which international standards govern installation and performance?

- Key standards include ISO 2531 (pipes/fittings), EN 545 (water pipeline), ASTM A536 (iron grades), and ANSI/AWWA C110/C153 (valve/fitting dimensions). All supplier products adhere to or exceed these requirements.

- 4. What coating options are available for anti-corrosion?

- Factory-applied coatings include zinc sprays, fusion bonded epoxy (≥70μm, ISO 8179), and bitumen. Custom dual-clad (zinc+FBE) coatings deliver salt-spray resistance up to 800 hours.

- 5. What is the typical delivery time for OEM/ODM orders?

- Standard lead time is 15–25 working days from final drawing and advance payment. Rapid prototypes (3D print+machining) possible as fast as 7–14 days depending on part geometry.

- 6. How is durability/lifetime validated?

- Lifespan is proven with ISO 2531 hydrostatic cycling, salt-spray, X-ray, and stress fatigue tests; major projects show 50–70 year operation without major failure.

- 7. Does supplier service include on-site installation or technical support?

- Yes: On-site supervision, virtual/AR installation guidance, full technical docs, and after-sales support via 24/7 multi-language team.

Delivery, Warranty, and After-Sales for Ductile Iron Supplier Service

- Lead Time: 15–25 working days typical; 24h fast-quote, urgent production for time-critical projects.

- Quality Guarantee: All products have 24-month warranty; free replacement/repair for any manufacturing defect (terms apply).

- Support Channels: Dedicated account manager, 24/7 technical hotline, remote AR-video troubleshooting, and field site visits upon request.

- Document Kit: Test certifications, full batch traceability, CAD drawings, installation guides provided with every shipment.

- Return Policy: 100% replacement for non-conformity; sample inspection before dispatch; flexible contract clauses for global customers.

Conclusion

When reliability, technical depth, and agile service matter, Ductile Iron Supplier Service stands as the leading source factory and powerful seller from China. Rely on deep industry expertise, strict quality control, and globally recognized certifications. Our capacity for customization, advanced CNC processes, robust coatings, and proven field applications enables lasting success across water, energy, petrochemical, and municipal projects

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025