- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Faoi . 13, 2025 13:46 Back to list

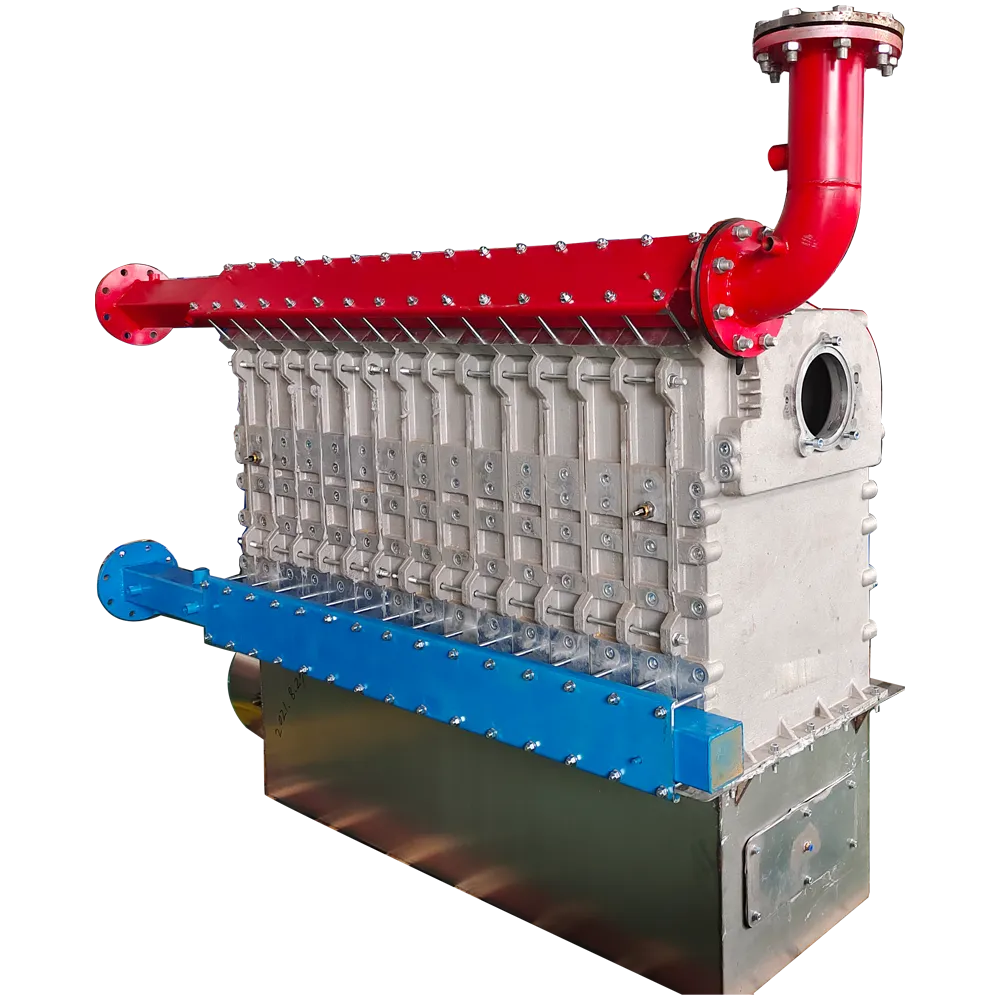

FULLY-PREMIXED LOW-NITROGEN CONDENSING BOILER FOR COMMERCIAL PURPOSE

In the realm of modern infrastructure, concrete pipes play a pivotal role in construction projects ranging from sewer systems to storm drains. A key component in the manufacturing of these pipes is the concrete pipe mold, specifically the bottom ring, which is essential for ensuring dimensional accuracy and structural integrity.

Furthermore, the trustworthiness of a bottom ring relies on rigorous testing and quality assurance measures. My extensive experience in the field underscores the importance of adopting a comprehensive evaluation protocol, which includes pressure testing and dimensional accuracy assessments. A lapse in these measures can lead to product failures that are not just inconvenient but also costly. In addition to mechanical and structural considerations, the ergonomic design of the bottom ring is a critical factor influencing efficiency and safety in the manufacturing environment. When designed thoughtfully, with attention to weight distribution and handling controls, these molds can minimize workplace injuries and optimize labor efforts, aligning with industry best practices for operational safety and worker wellbeing. Finally, as sustainable practices become increasingly central to construction methodologies, the development of eco-friendly materials for bottom rings is gaining traction. Recycling initiatives and the development of biodegradable composites are paving the way for transformative practices, favoring both ecological responsibility and enhanced mold performance. In conclusion, the SR Concrete Pipe Mold Bottom Ring is not merely an accessory in the manufacturing process but a cornerstone of efficiency and quality. Selecting a mold with precision-engineered bottom rings confirms a commitment to excellence in infrastructure development. Through continual innovation and an unwavering focus on standards, the industry can meet the rising demands for superior construction outcomes while fostering a culture of safety and sustainability.

Furthermore, the trustworthiness of a bottom ring relies on rigorous testing and quality assurance measures. My extensive experience in the field underscores the importance of adopting a comprehensive evaluation protocol, which includes pressure testing and dimensional accuracy assessments. A lapse in these measures can lead to product failures that are not just inconvenient but also costly. In addition to mechanical and structural considerations, the ergonomic design of the bottom ring is a critical factor influencing efficiency and safety in the manufacturing environment. When designed thoughtfully, with attention to weight distribution and handling controls, these molds can minimize workplace injuries and optimize labor efforts, aligning with industry best practices for operational safety and worker wellbeing. Finally, as sustainable practices become increasingly central to construction methodologies, the development of eco-friendly materials for bottom rings is gaining traction. Recycling initiatives and the development of biodegradable composites are paving the way for transformative practices, favoring both ecological responsibility and enhanced mold performance. In conclusion, the SR Concrete Pipe Mold Bottom Ring is not merely an accessory in the manufacturing process but a cornerstone of efficiency and quality. Selecting a mold with precision-engineered bottom rings confirms a commitment to excellence in infrastructure development. Through continual innovation and an unwavering focus on standards, the industry can meet the rising demands for superior construction outcomes while fostering a culture of safety and sustainability.

Share

Pervious:

Latest news

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025