નવેમ્બર . 19, 2024 16:45 Back to list

Cast Aluminum Silicon Heat Exchangers for Industrial Hot Water Boiler Applications

The Role of Cast Silicon Aluminum Heat Exchangers in Hot Water Boilers

In the realm of industrial heating, the efficiency and reliability of heat exchangers are of paramount importance, particularly in hot water boilers. Among the various materials used to manufacture these critical components, cast silicon aluminum has emerged as a preferred choice for many manufacturers. This article explores the significance of cast silicon aluminum heat exchangers, their benefits, and their application in hot water boiler factories.

Understanding Cast Silicon Aluminum

Cast silicon aluminum is an alloy that combines silicon and aluminum, enhancing the material’s strength, corrosion resistance, and thermal conductivity. This alloy has increasingly been recognized for its superior casting properties, allowing for the production of complex shapes that are essential for effective heat transfer in heat exchangers. The combination of aluminum’s lightweight nature and silicon's ability to improve fluidity during the casting process makes this alloy a versatile option for various applications.

Importance of Heat Exchangers in Hot Water Boilers

Heat exchangers are critical components in hot water boilers, facilitating the transfer of heat from the combustion gases to the water circulating within the system. They must endure high temperatures and pressures while maintaining efficiency over prolonged operational periods. The design and material of heat exchangers greatly influence the boilers' overall performance, energy efficiency, and longevity.

Advantages of Cast Silicon Aluminum Heat Exchangers

1. Corrosion Resistance One of the primary advantages of cast silicon aluminum is its resistance to corrosion. In hot water applications, where moisture and various chemicals may be present, this property is vital. Traditional alloys may degrade over time due to corrosion, which can lead to leaks and reduced efficiency. The enhanced durability of silicon aluminum extends the lifespan of heat exchangers, resulting in lower maintenance costs.

2. High Thermal Conductivity The thermal conductivity of cast silicon aluminum is significantly higher than that of many other materials, allowing for more effective heat transfer. This characteristic enables hot water boilers to operate more efficiently, reducing energy consumption and operational costs. As energy efficiency becomes a more pressing concern across industries, the advantages of using high-conductivity materials cannot be overstated.

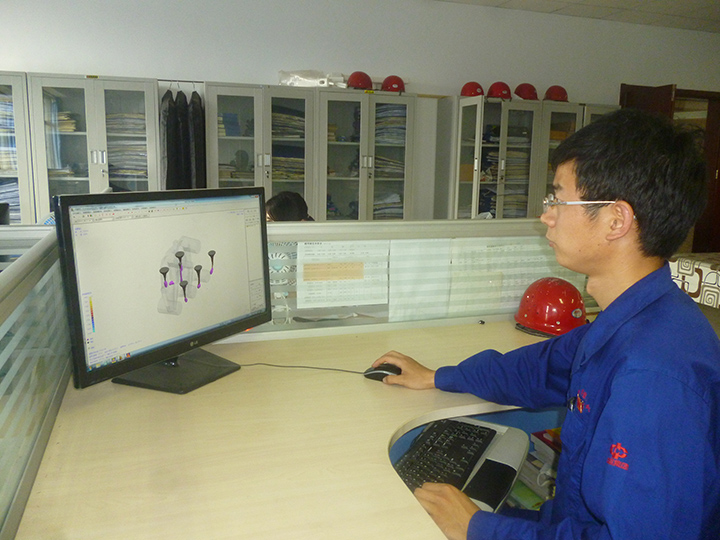

cast silicon aluminum heat exchanger for hot water boiler factories

3. Lightweight Another benefit of cast silicon aluminum is its lightweight nature. This characteristic reduces the overall weight of the heat exchanger, which is particularly advantageous for installation and transportation. Lightweight components also contribute to less structural stress in the boiler system, enhancing safety and operational stability.

4. Versatility in Design The excellent castability of silicon aluminum allows manufacturers to create intricate designs and complex geometries. This flexibility enables the development of heat exchangers that maximize surface area and improve heat transfer capabilities, tailored specifically for different boiler applications.

5. Cost-Effectiveness While the initial investment in cast silicon aluminum heat exchangers may be higher than other materials, their durability and efficiency can lead to significant savings over time. Reduced maintenance needs and lower energy costs contribute to their overall cost-effectiveness, making them a smart choice for hot water boiler factories.

Applications in Hot Water Boiler Factories

In hot water boiler factories, the implementation of cast silicon aluminum heat exchangers can lead to improved product offerings. As manufacturers focus on creating more efficient and durable heating systems, utilizing advanced materials like silicon aluminum becomes essential. Modern consumers demand reliability and performance, especially in commercial and industrial applications where downtime can be costly.

Additionally, the move towards sustainability and energy efficiency in the industrial sector has driven the adoption of innovative materials. Companies that utilize cast silicon aluminum in their heat exchanger designs are better positioned to meet regulatory requirements and customer expectations for eco-friendly solutions.

Conclusion

The integration of cast silicon aluminum heat exchangers in hot water boilers represents a significant advancement in heating technology. With their superior corrosion resistance, high thermal conductivity, lightweight nature, design versatility, and cost-effectiveness, these materials are setting a new standard in the industry. As manufacturers continue to prioritize efficiency and sustainability, cast silicon aluminum will undoubtedly play a pivotal role in the future of hot water boiler factories, ensuring that they meet both current and future demands efficiently and effectively.

-

Premium Cast Iron Water Main Pipe for Robust Infrastructure

NewsAug.27,2025

-

A-Rated Cast Aluminum Boilers: High-Efficiency Condensing Gas & LPG

NewsAug.26,2025

-

OEM Cast Silicon Aluminum Alloy Heat Exchanger | Custom & High Performance

NewsAug.25,2025

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025