ઓગસ્ટ . 27, 2025 00:40 Back to list

Premium Cast Iron Water Main Pipe for Robust Infrastructure

Advanced Solutions in Water Infrastructure: The Role of Cast Iron Water Main Pipes

In the intricate landscape of modern municipal and industrial infrastructure, the reliability and longevity of water conveyance systems are paramount. Among the foundational materials, cast iron water main pipe stands as a testament to enduring performance and robust engineering. This material has been a cornerstone of water distribution for centuries, evolving significantly with advancements in metallurgy and manufacturing processes. From its traditional form to modern iterations like ductile iron, cast iron continues to be a preferred choice for its strength, corrosion resistance, and cost-effectiveness in diverse applications, including water supply, drainage, and industrial fluid transport.

This discourse will delve into the technical intricacies, manufacturing excellence, application versatility, and strategic advantages that position cast iron piping as an indispensable component in today's demanding infrastructure projects. We will explore its evolution, industry best practices, and the rigorous standards that ensure its unparalleled performance.

Industry Trends and Market Dynamics for Water Mains

The global water infrastructure market is experiencing significant transformation, driven by aging infrastructure, population growth, urbanization, and increasing demands for sustainable water management. Key trends influencing the demand for water main pipes include:

- Infrastructure Renewal: Many developed nations are undertaking massive projects to replace or rehabilitate pipelines installed over 50-100 years ago. This creates a sustained demand for durable and long-lasting materials like cast iron water main pipe and its ductile iron variants.

- Smart Water Networks: Integration of IoT and sensor technologies for leak detection, pressure management, and real-time monitoring is becoming standard, requiring pipes that can withstand instrumentation and offer long-term stability.

- Sustainability and Resilience: Emphasis on materials with lower environmental footprints, high recyclability, and exceptional resilience against seismic activity and ground shifts is growing. Ductile iron, a modern form of cast iron, excels in these areas.

- Increased Pressure Ratings: Modern water distribution systems often operate at higher pressures, necessitating pipes with superior tensile strength and burst resistance, a characteristic where centrifugally cast iron pipe truly shines.

- Specialized Linings and Coatings: To combat internal corrosion and tuberculation, advanced internal linings (e.g., cement mortar, epoxy) and external coatings are becoming standard, extending pipe service life and maintaining water quality.

The market for municipal water and wastewater pipes is projected to grow, with cast and ductile iron pipes maintaining a substantial share due to their proven track record and continuous innovation in performance and installation efficiency.

Manufacturing Process: Precision Engineering of Cast Iron Pipes

The production of high-quality cast iron water main pipe involves a sophisticated sequence of metallurgical and mechanical processes, designed to impart strength, durability, and corrosion resistance. The predominant method for modern water mains is centrifugal casting, producing what is known as centrifugally cast iron pipe or centrifugally cast iron. This process ensures a dense, uniform, and structurally sound product.

Process Flow: Centrifugal Casting Method

Step 1: Raw Material Preparation

High-quality pig iron, steel scrap, and alloying elements (e.g., magnesium for ductile iron) are meticulously selected and melted in induction or electric arc furnaces at precise temperatures, typically above 1400°C.

Step 2: Molten Metal Treatment

For ductile iron, molten iron undergoes a magnesium treatment to spheroidize the graphite flakes, enhancing ductility and impact resistance. This is a critical distinction from gray cast iron.

Step 3: Centrifugal Casting

Molten metal is poured into a rapidly rotating metal mold. Centrifugal force pushes the metal against the mold wall, creating a dense, uniform pipe wall free from voids and slag inclusions. This forms the basis of centrifugally cast iron pipe production.

Step 4: Annealing

Pipes are heat-treated in an annealing furnace to relieve internal stresses, optimize microstructure, and enhance mechanical properties like strength and impact resistance.

Step 5: Finishing and Machining

Pipes are cut to specified lengths, and ends are precisely machined (e.g., bell and spigot, flanged) using CNC machining to ensure accurate joint dimensions and ease of installation. This includes beveling for welding or preparation for mechanical joints.

Step 6: Coating and Lining

Internal linings (e.g., cement mortar lining for potable water, epoxy for wastewater) and external coatings (e.g., zinc coating with bitumen, epoxy) are applied to protect against corrosion and ensure water quality. This is crucial for the long service life of cast iron water main pipe.

Step 7: Testing and Quality Control

Each pipe undergoes rigorous testing including hydrostatic pressure testing, dimensional checks (e.g., cast iron outside diameter, wall thickness), coating adhesion tests, and material composition analysis. Compliance with standards such as ISO 2531, EN 545, AWWA C150/C151, and ANSI specifications is verified.

The typical service life of a well-maintained cast iron water main pipe can exceed 100 years, with many installations still functional after 150 years. Target industries include municipal water supply & drainage, petrochemical, metallurgy, mining, and fire protection systems, where robust, corrosion-resistant, and high-pressure capabilities are critical. The inherent advantages, such as energy saving through smooth internal linings (reducing pumping costs) and superior corrosion resistance when properly coated, are significant in these demanding environments.

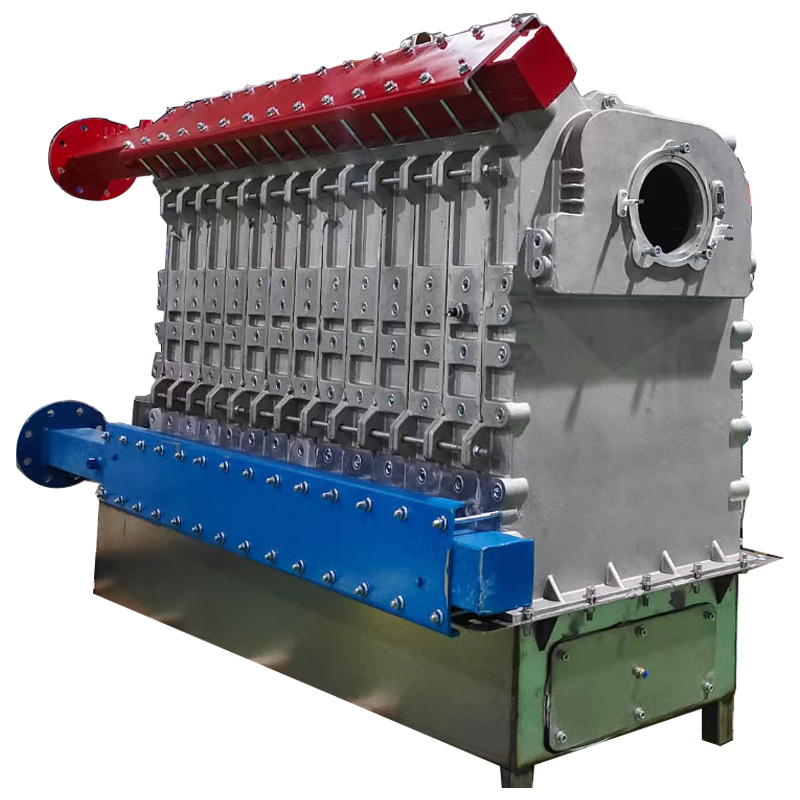

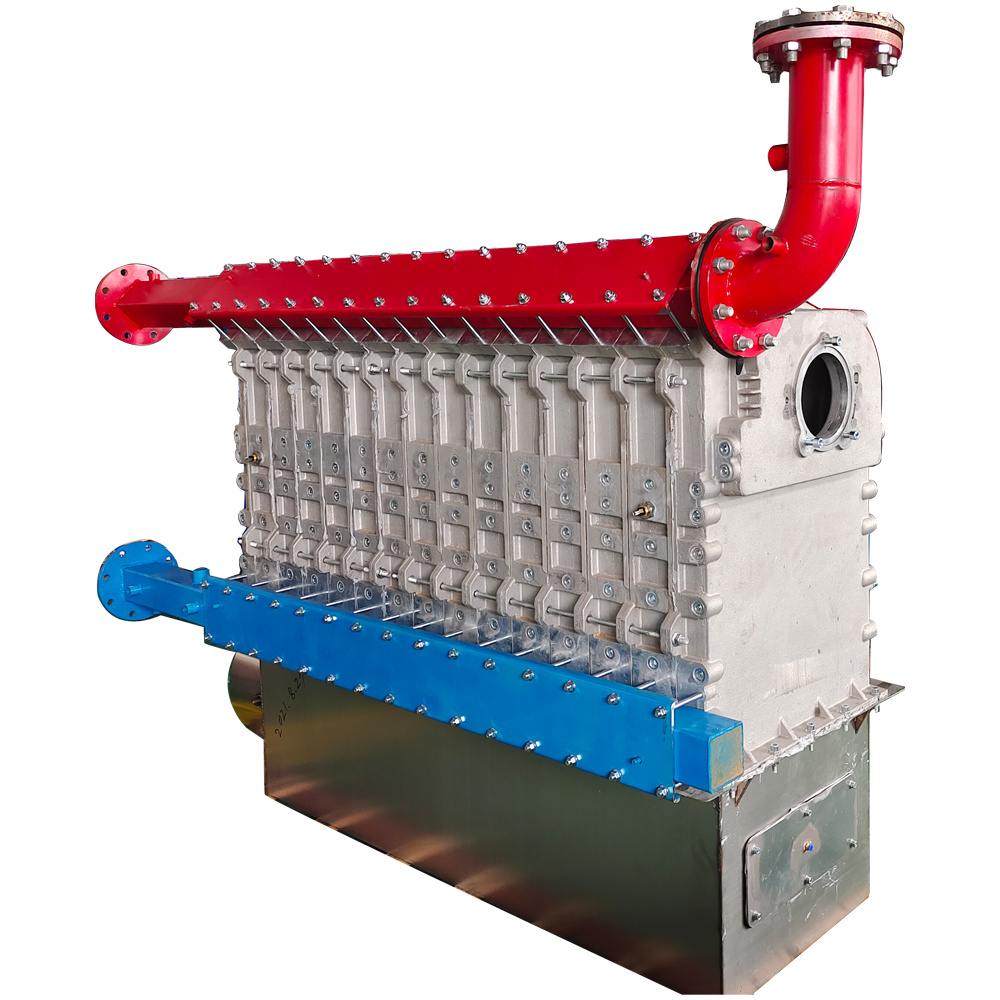

Image: Overview of a modern pipe manufacturing facility, highlighting precision and scale.

Technical Specifications and Performance Parameters

Understanding the detailed technical specifications of cast iron water main pipe is crucial for engineers and project managers. These parameters dictate suitability for various applications, ensuring optimal performance and compliance with regulatory requirements. Modern ductile iron pipes, a direct evolution, offer superior mechanical properties.

Ductile Iron Pipe (DIP) Standard Specifications (AWWA C151/A21.51)

| Parameter | Description / Value | Standard Reference |

|---|---|---|

| Material Type | Ductile Iron (with spheroidized graphite) | AWWA C151 |

| Tensile Strength | Min. 414 MPa (60,000 psi) | AWWA C151 |

| Yield Strength | Min. 289 MPa (42,000 psi) | AWWA C151 |

| Elongation | Min. 10% | AWWA C151 |

| Nominal Pipe Sizes (NPS) | DN 100 to DN 2000 (4-inch to 84-inch) | AWWA C151, ISO 2531 |

| Pressure Classes (Design Working Pressure) | Vary by size, e.g., Class 350 (350 psi / 24 bar) to Class 50 (50 psi / 3.4 bar) | AWWA C150 |

| Standard Lengths | 5.5m (18 ft) or 6.0m (20 ft) | Industry Standard |

| Joint Types | Push-on, Mechanical, Flanged, Restrained | AWWA C110/C111 |

| Internal Lining | Cement mortar lining (CML) as per AWWA C104/ISO 4179; Epoxy coating | AWWA C104 |

| External Coating | Zinc coating + bitumen, Epoxy, Polyethylene sleeving | AWWA C151, ISO 8179 |

| Corrosion Resistance | Excellent in most soil conditions, enhanced by coatings | N/A (Material property) |

The selection of pipe class, lining, and coating depends heavily on the specific application, soil corrosivity, water quality, and operating pressures. It is essential to consult these standards when specifying a cast iron water main pipe project. The precise control over parameters like `cast iron outside diameter` and wall thickness ensures compatibility with a wide range of fittings and accessories.

Versatile Application Scenarios

The robust nature and adaptable characteristics of cast iron water main pipe lend it to an extensive array of applications across various sectors. Its proven durability makes it a preferred material for critical infrastructure.

- Potable Water Distribution: The primary application. Ductile iron pipes, with their cement mortar linings, ensure clean, safe conveyance of drinking water from treatment plants to consumers, minimizing leakage and maintaining water quality over decades.

- Wastewater and Sewer Systems: Designed to handle various effluents, `cast drain pipe` and `cast iron drain pipes for sale` are essential for gravity and pressurized sewer lines. Specialized linings can withstand corrosive wastewater environments.

- Fire Protection Systems: High-pressure `cast iron water main pipe` is critical for fire hydrants and sprinkler systems in urban and industrial settings, providing reliable water flow under demanding conditions.

- Industrial Process Piping: In petrochemical plants, mining operations, and manufacturing facilities, `cast iron conduit` and pipe systems transport raw materials, process water, and finished products, valued for their resistance to abrasion and impact.

- Agricultural Irrigation: Large diameter cast iron pipes are used in large-scale irrigation projects, providing efficient water delivery to agricultural lands.

- Heating and Cooling Systems: Though less common for modern primary heating circuits (which often use `cast iron heating pipes` for radiators/boilers), some large-scale district cooling networks utilize the strength and longevity of cast iron.

Image: Installation of ductile iron pipes in an urban water project.

The adaptability of pipe jointing methods, from traditional push-on gaskets to mechanical and restrained joints, further expands their suitability for diverse terrains and installation challenges, including areas prone to seismic activity.

Technical Advantages of Cast Iron Water Main Pipes

The sustained preference for cast iron water main pipe, especially its ductile iron variant, is underpinned by a compelling suite of technical advantages that offer superior value over the lifecycle of an infrastructure project.

- Exceptional Strength and Durability: Ductile iron possesses high tensile strength (60,000 psi) and yield strength (42,000 psi), making it resistant to external loads, ground movement, and internal pressure surges. This translates to fewer breaks and leaks compared to other materials, ensuring robust performance for decades.

- Impact Resistance: Its inherent ductility allows `cast ductile iron pipe` to absorb significant impact energy without fracturing, a critical advantage during transportation, installation, and in areas prone to accidental excavation or seismic events.

- Corrosion Resistance: While iron can corrode, modern `centrifugally cast iron pipe` is protected by advanced internal linings (cement mortar is standard for water) and external coatings (zinc-aluminum alloys with bitumen or epoxy). These layers provide a formidable barrier against aggressive soils and corrosive water, drastically extending service life.

- Pressure Rating Performance: Engineered to withstand high internal pressures, ductile iron pipes are ideal for municipal water transmission and distribution systems that operate under significant head pressure. They easily meet and exceed industry pressure class requirements.

- Joint Integrity and Leakage Control: Advanced joint designs, such as push-on and mechanical joints with elastomeric gaskets, provide leak-tight seals and allow for minor deflection, accommodating ground shifts without compromising system integrity. Restrained joints offer additional security in thrust restraint applications.

- Flow Efficiency: Smooth internal linings, particularly cement mortar, reduce friction losses within the pipe. This translates to lower pumping costs and improved energy efficiency over the pipeline's operational life, contributing to significant energy saving.

- Sustainability: Cast iron products, including `cast ductile iron pipe`, are highly recyclable, with a significant portion of new pipes produced from recycled materials. This reduces the environmental footprint and supports circular economy principles.

- Cost-Effectiveness: While initial installation costs might be comparable to other materials, the extended service life, minimal maintenance requirements, and reduced leakage rates of `buy cast iron pipe` solutions result in a lower total cost of ownership (TCO) over the project's lifespan.

Image: Sectional view of a ductile iron pipe with internal lining and external coating.

Vendor Comparison and Selection Criteria

Selecting the right vendor for cast iron water main pipe is a strategic decision that impacts project success, longevity, and overall cost. B2B decision-makers should evaluate vendors based on a comprehensive set of criteria beyond mere price.

Key Evaluation Criteria for Pipe Suppliers:

| Criteria | Importance | Considerations |

|---|---|---|

| Product Quality & Standards | High | Adherence to ISO 2531, EN 545, AWWA C150/C151. Consistency in material properties, `cast iron outside diameter` tolerance, and coating quality. |

| Manufacturing Capabilities | High | Use of advanced centrifugal casting, in-house quality control labs, capacity for large-scale and specialized orders. |

| Certifications & Compliance | Critical | ISO 9001 (Quality Management), ISO 14001 (Environmental Management), NSF/ANSI 61 (for potable water components), WRAS (UK), etc. |

| Experience & Reputation | High | Years in business, track record, client testimonials, successful past projects, market recognition for `centrifugally cast iron pipe`. |

| Technical Support & Expertise | Medium-High | Availability of engineering support, installation guidance, design assistance, and problem-solving expertise. |

| Logistics & Lead Times | Medium | Reliable delivery schedules, efficient supply chain management, ability to handle urgent requirements for `cast iron drain pipes for sale` or water mains. |

| Customization Options | Medium | Flexibility to provide specific lengths, custom coatings, non-standard pressure classes, or specialized fittings. |

A thorough due diligence process ensures partnership with a vendor who can consistently deliver high-quality products and support, crucial for the long-term success of any water infrastructure project.

Customized Solutions for Unique Project Requirements

While standard `cast ductile iron pipe` products cater to a broad range of applications, many complex projects demand tailored solutions. Reputable manufacturers offer extensive customization options to meet specific environmental, operational, or logistical challenges.

- Specialized Linings and Coatings: Beyond standard cement mortar lining and zinc-bitumen coating, options include epoxy, polyurethane, or ceramic linings for highly corrosive fluids or extreme pH levels. External coatings can be customized for severely aggressive soil conditions or submarine applications.

- Non-Standard Dimensions: Projects may require pipes with unique lengths or specific `cast iron outside diameter` to integrate with existing infrastructure or fit confined spaces. Manufacturers can provide custom pipe lengths, reducing cutting waste on-site.

- Specific Pressure Classes: For ultra-high-pressure transmission lines or low-pressure gravity systems, pipes can be manufactured to specific pressure ratings that fall outside standard classes, optimizing material usage and cost.

- Custom Fittings and Specials: Fabricated fittings like bends, reducers, tees, and tapers can be custom-made to exact project dimensions and angles, simplifying complex pipeline layouts and connections.

- Integrated Joint Solutions: Developing bespoke jointing solutions for unique geological challenges (e.g., highly seismic zones requiring enhanced flexibility) or specific installation techniques (e.g., trenchless technology).

- Logistical Packaging: Custom packaging or crating for challenging transport routes or international shipping can be arranged to minimize damage and ease handling at the project site.

Image: Specialized ductile iron pipe fittings for complex network connections.

Engaging with manufacturers that possess robust R&D capabilities and flexible production lines ensures that even the most stringent project specifications for cast iron water main pipe can be met with engineered precision.

Application Case Studies: Proving Reliability in Action

Real-world deployments vividly illustrate the enduring reliability and performance of cast iron water main pipe in challenging environments. These examples underscore its critical role in modern infrastructure.

Case Study 1: Urban Water Main Replacement Project

Client: Major Metropolitan Water Utility

Location: Densely Populated Downtown Area, North America

Challenge: Replacing 100-year-old gray cast iron mains susceptible to frequent breaks, leading to significant water loss and service disruptions. The area required minimal disruption to traffic and businesses, and the new pipes needed to withstand heavy traffic loads and dynamic soil conditions.

Solution: DN 600 (`cast iron outside diameter` ~650mm) `cast ductile iron pipe` with restrained joints and cement mortar lining was selected. The project utilized trenchless installation techniques where feasible, leveraging the pipe's robust mechanical strength and ease of jointing.

Outcome: Over 15 km of new water mains were installed over two years. The ductile iron pipes offered superior resistance to external loads, reduced installation time due to efficient jointing, and virtually eliminated leakage. The client reported a 20% reduction in water loss in the serviced area and improved pressure stability, receiving positive feedback from both operational teams and the community for enhanced service reliability.

Case Study 2: Industrial Water Supply to a Petrochemical Complex

Client: International Petrochemical Corporation

Location: Coastal Industrial Zone, Middle East

Challenge: Establishing a reliable raw water supply line through highly corrosive saline soils and extreme temperatures to support expansion of a petrochemical facility. The line needed to handle high flow rates and continuous operation without failure.

Solution: Large diameter (DN 1200) `centrifugally cast iron pipe` with enhanced external zinc-aluminum alloy coating and a thick epoxy internal lining was specified. Flanged joints were used for critical connections within the plant boundary to ensure maximum integrity under operational stresses.

Outcome: The pipeline, spanning 25 km, has been operational for over a decade with zero reported external corrosion failures despite the aggressive environment. The robust construction and specialized coatings have maintained structural integrity and delivered consistent water supply, supporting uninterrupted industrial processes and contributing to the plant's operational efficiency and safety record.

Image: Large diameter ductile iron pipes ready for installation in an industrial setting.

Ensuring Trustworthiness: FAQ, Lead Times, Warranty, and Support

For B2B clients, trustworthiness is built not just on product quality, but also on comprehensive support and transparent operational policies.

Frequently Asked Questions (FAQ)

A: Grey cast iron has graphite flakes, making it brittle. Ductile iron (DI) is treated with magnesium to spheroidize the graphite, significantly increasing its ductility, tensile strength, and impact resistance. Modern water mains predominantly use DI pipes due to their superior performance.

Q: Are cast iron pipes suitable for potable water?A: Yes, `cast ductile iron pipe` is widely used for potable water. When lined internally with cement mortar (conforming to AWWA C104 or ISO 4179) and appropriately certified (e.g., NSF/ANSI 61), they are safe and effective for drinking water transmission.

Q: How does `centrifugally cast iron pipe` compare in terms of cost to other pipe materials?A: While initial material costs might be higher than some plastic alternatives, the total installed cost and lifecycle cost of `buy cast iron pipe` solutions are often lower. Factors include faster installation, less need for bedding material, superior durability, minimal maintenance, and extended service life (100+ years), which lead to a lower total cost of ownership.

Q: What is the typical lead time for large orders of `cast iron water main pipe`?A: Lead times vary based on pipe size, quantity, customization requirements, and current production schedules. For standard items, lead times can range from 4-8 weeks. For highly customized or very large orders, this may extend to 12-16 weeks. We recommend consulting with our sales team for precise lead time estimates for your specific project.

Lead Time and Fulfillment

Our streamlined manufacturing processes and robust supply chain management enable efficient fulfillment of orders, from standard `cast iron water main pipe` to complex customized solutions. We prioritize clear communication regarding production timelines and logistical arrangements to ensure timely project completion. Expedited production options may be available for urgent requirements, subject to capacity and material availability.

Image: Quality control station ensuring adherence to dimensional specifications.

Warranty Commitments

We stand by the superior quality of our `centrifugally cast iron pipe` products. All pipes are backed by a comprehensive warranty against manufacturing defects and material failures under normal operating conditions. The standard warranty period for our ductile iron pipes is typically 10 years, reflecting our confidence in their design, materials, and manufacturing excellence. Specific warranty terms will be provided with each quotation and order confirmation.

Customer Support and After-Sales Service

Our commitment extends beyond product delivery. We offer robust after-sales support, including technical assistance for installation, troubleshooting, and maintenance guidance. Our team of experienced engineers and customer service representatives is available to address any inquiries or challenges that may arise throughout the project lifecycle, ensuring optimal performance and longevity of your `cast iron water main pipe` systems.

Conclusion

The evolution of `cast iron water main pipe`, particularly into modern ductile iron, signifies a triumph of engineering and materials science. Its unparalleled combination of strength, ductility, corrosion resistance, and longevity makes it an indispensable material for critical water infrastructure worldwide. As global demands for reliable and sustainable water systems continue to intensify, ductile iron pipes remain at the forefront, offering proven performance and significant economic advantages over their extended service life. Investing in high-quality `cast iron water main pipe` is an investment in resilient, efficient, and future-proof infrastructure.

References

- AWWA Standards for Ductile-Iron Pipe and Fittings. American Water Works Association.

- ISO 2531: Ductile iron pipes, fittings, accessories and their joints for water applications. International Organization for Standardization.

- Ductile Iron Pipe Research Association (DIPRA) Publications.

- Water and Wastewater Industry Market Reports, Grand View Research.

- Corrosion Control of Ductile Iron Pipe, NACE International.

-

A-Rated Cast Aluminum Boilers: High-Efficiency Condensing Gas & LPG

NewsAug.26,2025

-

OEM Cast Silicon Aluminum Alloy Heat Exchanger | Custom & High Performance

NewsAug.25,2025

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025