- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ડીસેમ્બર . 15, 2024 14:15 Back to list

milling body casting exporters

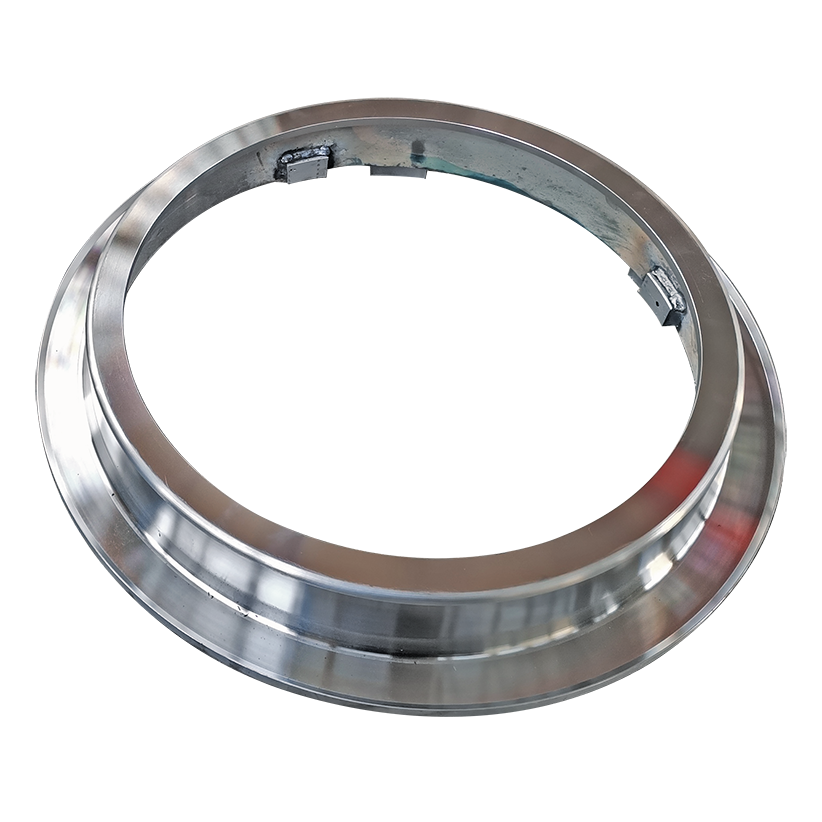

Exploring the World of Milling Body Casting Exporters

Milling has long been a crucial process in various industries, ranging from food production to metalworking. In this context, milling body casting plays a vital role. The manufacturing and export of milling body castings represent not just a sector but a significant contributor to international trade. This article delves into the value of milling body casting exporters, the intricacies of their operations, and the factors influencing their success.

Milling body casting involves the process of creating components used in mills, which are essential for grinding and processing materials. The casting process typically utilizes metals and alloys that provide durability and strength, thereby ensuring the longevity of the machinery. The quality of these castings directly impacts the efficiency and effectiveness of the milling process.

Importance of Quality in Milling Body Castings

The primary consideration for milling body casting exporters is quality. Exporters must ensure that their products meet international standards to cater to a global market. High-quality castings not only enhance the performance of milling equipment but also reduce downtime and maintenance costs for end-users. This emphasis on quality ensures a competitive edge in the market, as manufacturers seek reliable components that can withstand the rigors of operation.

The selection of raw materials is crucial. Exporters often source high-grade metals and alloys, including cast iron, steel, and specialized composites, to meet the specific requirements of different milling applications. Quality control processes are implemented throughout manufacturing to consistently monitor and ensure that the final product adheres to rigorous standards.

Market Demand and Trends

The demand for milling body castings is driven by several factors, including industrial growth, technological advancements, and increased manufacturing activities globally. Emerging markets, particularly in Asia and Africa, present significant opportunities for exporters as these regions experience industrial expansions. Additionally, the ongoing digital transformation in manufacturing is leading to the development of advanced milling technologies, further driving the need for quality castings.

Another trend influencing the milling body casting market is the growing emphasis on sustainability. Companies are increasingly looking for eco-friendly casting solutions and materials that minimize environmental impact. Exporters are adapting to these trends by investing in cleaner production methods and developing innovative materials that align with sustainability goals.

milling body casting exporters

The Role of Technology in Exporting

In the current landscape, technology plays a critical role in enhancing the capabilities of milling body casting exporters. Modern manufacturing techniques such as 3D printing and computer numerical control (CNC) machining have revolutionized the casting process, allowing for more precise and intricately designed components. The adoption of these technologies has not only improved product quality but also shortened lead times, enabling exporters to meet the fast-paced demands of the global market.

Moreover, digital platforms and online marketplaces have transformed the way exporters connect with buyers. Companies can now reach a global audience more efficiently, showcasing their products and capabilities to potential clients without being restricted by geographical boundaries.

Challenges Faced by Exporters

Despite the promising prospects, milling body casting exporters face several challenges. Fluctuations in raw material prices can significantly impact profit margins, and stringent regulations regarding environmental standards can complicate manufacturing processes. Additionally, supply chain disruptions, as witnessed during the COVID-19 pandemic, have forced exporters to reevaluate their logistics strategies.

To navigate these challenges, exporters must adopt robust risk management strategies and remain agile in their operations. Continuous investment in research and development will also be necessary to innovate and improve product offerings continually.

Conclusion

Milling body casting exporters play an essential role in the manufacturing ecosystem, providing high-quality components that drive efficiency and performance in various industries. As global demand continues to rise, these exporters must stay ahead of market trends, embrace technological advancements, and prioritize quality and sustainability. By doing so, they can ensure their continued success in an ever-evolving landscape while contributing significantly to international trade. The future of milling body castings is bright, and the potential for growth in this field is immense, making it an exciting area for industry players and stakeholders alike.

-

Durable Cast Iron Water Main Pipe | AI-Optimized Design

NewsAug.05,2025

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025