- Afirka

- Albaniya

- Amharic

- Larabci

- Armenian

- Azabaijan

- Basque

- Belarushiyanci

- Bengali

- Bosniya

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Yaren mutanen Holland

- Turanci

- Esperanto

- Estoniya

- Finnish

- Faransanci

- Farisa

- Galiciyan

- Jojin

- Jamusanci

- Girkanci

- Gujarati

- Haitian Creole

- hausa

- hawayi

- Ibrananci

- A'a

- Miya

- Harshen Hungary

- Icelandic

- igbo

- Indonesiya

- Irish

- Italiyanci

- Jafananci

- Yawanci

- Kannada

- kazakh

- Khmer

- Ruwanda

- Yaren Koriya

- Kurdish

- Kyrgyzstan

- Aiki

- Latin

- Latvia

- Lithuaniyanci

- Luxembourg

- Makidoniya

- Malgashi

- Malay

- Malayalam

- Maltase

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Yaren mutanen Norway

- Yaren mutanen Norway

- Occitan

- Pashto

- Farisa

- Yaren mutanen Poland

- Fotigal

- Punjabi

- Romanian

- Rashanci

- Samoan

- Scottish Gaelic

- Serbian

- Turanci

- Shona

- Sindhi

- Sinhala

- Slovak

- Harshen Sloveniya

- Somaliya

- Mutanen Espanya

- Sundanci

- Harshen Swahili

- Yaren mutanen Sweden

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Baturke

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Taimako

- Yadish

- Yarbawa

- Zulu

Feb . 21, 2025 11:38 Komawa zuwa lissafi

From Mold to Masterpiece: Supercharge Your Concrete Pipe Production!

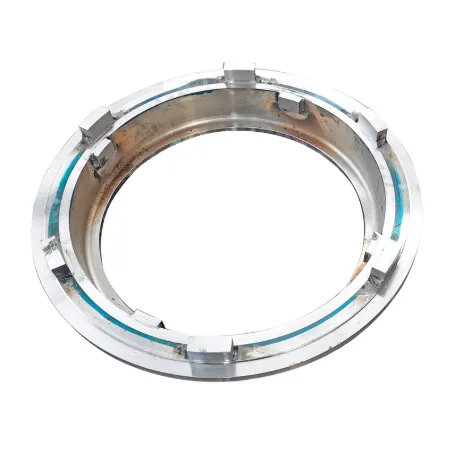

In the concrete pipe manufacturing industry, the quality of the concrete pipe mould pallet is crucial in determining the efficiency and durability of the final product. These pallets serve as the foundation for the pipe production process, ensuring precise shapes and strong, reliable pipes.

The Role of a Concrete Pipe Mould Pallet in Production

The concrete pipe mould pallet is one of the most essential tools in concrete pipe manufacturing. It shapes the pipe and supports the curing process, ensuring that each product meets the necessary strength and durability standards. Whether used for cast steel cement pipe mould pallets or cast iron cement pipe mold pallets, these pallets ensure the pipes are formed with precision and consistency.

Using high-quality pallets such as the cast steel cement pipe mould pallet can significantly improve the production rate, as it provides more durability and can withstand the pressure of curing concrete, leading to a reduction in repair costs and longer pallet life. This makes them an excellent choice for manufacturers looking to streamline operations and reduce overall production costs.

The Efficiency of Stamp Cement Pipe Mold Pallets

For manufacturers looking for precision and high-volume production, the stamp cement pipe mold pallet is an invaluable tool. This type of pallet uses a stamping process to create uniform molds for the concrete pipes. The stamp cement pipe mold pallet ensures that each pipe has the same size, shape, and finish, which is crucial for industries requiring standardized and high-quality pipes for large-scale projects.

With this pallet, manufacturers can significantly increase their productivity while ensuring a consistently high level of quality. The stamping process also minimizes waste, as it helps in efficiently utilizing the concrete mixture and reducing material costs. As a result, the stamp cement pipe mold pallet is perfect for both large and small-scale concrete pipe manufacturers seeking to optimize their processes.

Punch Cement Pipe Mold Pallets: Perfect for Precision and Strength

Another essential tool in modern concrete pipe production is the punch cement pipe mold pallet. These pallets use punching technology to create precise shapes for the concrete pipes, ensuring that they meet the required specifications. The punch cement pipe mold pallet is especially beneficial in high-speed production environments, as it ensures quick and efficient molding with minimal human intervention.

The punch cement pipe mold pallet is ideal for manufacturers who need to maintain tight tolerances and produce large volumes of pipes without compromising on quality. Its precision and durability make it a preferred choice in the industry for achieving both speed and high-strength concrete pipes.

Cast Iron Cement Pipe Mold Pallets: Durability and Long-Term Use

For concrete pipe producers working with large-scale operations, the cast iron cement pipe mold pallet is an essential investment. Cast iron provides excellent strength and durability, making it ideal for producing high-quality pipes that can withstand high pressure and harsh environmental conditions. The cast iron cement pipe mold pallet is known for its ability to last longer under demanding conditions, reducing maintenance costs and downtime in production.

This type of pallet is particularly suitable for heavy-duty applications where concrete pipes need to endure extreme pressure and weight, such as in water distribution systems or sewage infrastructure. The cast iron cement pipe mold pallet ensures that the pipes produced are reliable and strong enough for these applications, making it an essential tool for industries focused on durability.

Streamlining Production with Cast Steel Cement Pipe Mould Pallets

The cast steel cement pipe mould pallet offers several advantages in terms of both performance and longevity. It combines the strength of steel with the ability to withstand the harsh conditions of concrete molding. This type of pallet is particularly beneficial for producing pipes with smooth finishes and precise dimensions, ensuring uniformity across a large batch of products.

The cast steel cement pipe mould pallet can handle the rigors of the curing process and can last longer than many other types of pallets. Its durability and robustness make it an excellent choice for manufacturers who need to maximize their production efficiency while ensuring the highest quality of concrete pipes.

Investing in high-quality mold pallets is not just about improving product quality; it’s about enhancing the overall efficiency of your operations, reducing costs, and ensuring that every concrete pipe produced is a masterpiece of durability and precision.

-

The Ultimate Choice for Optimal Thermal Exchange: Hex Heat Exchangers

LabaraiJun.24,2025

-

Hydronic Gas Boiler: The Efficient Heating Solution For Your Needs

LabaraiJun.24,2025

-

Discover the Efficiency of Mini Boiler Gas

LabaraiJun.24,2025

-

Concrete Pipe Mold Pallet Solutions

LabaraiJun.24,2025

-

Unveiling the Benefits of Light Pallet Mould

LabaraiJun.24,2025

-

Discover the Benefits of Ductile Cast Iron Pipe Mold Pallet

LabaraiJun.24,2025