- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

נוב . 25, 2024 04:54 Back to list

ductile casting exporter

The Importance of Ductile Iron Casting Exporters in Global Trade

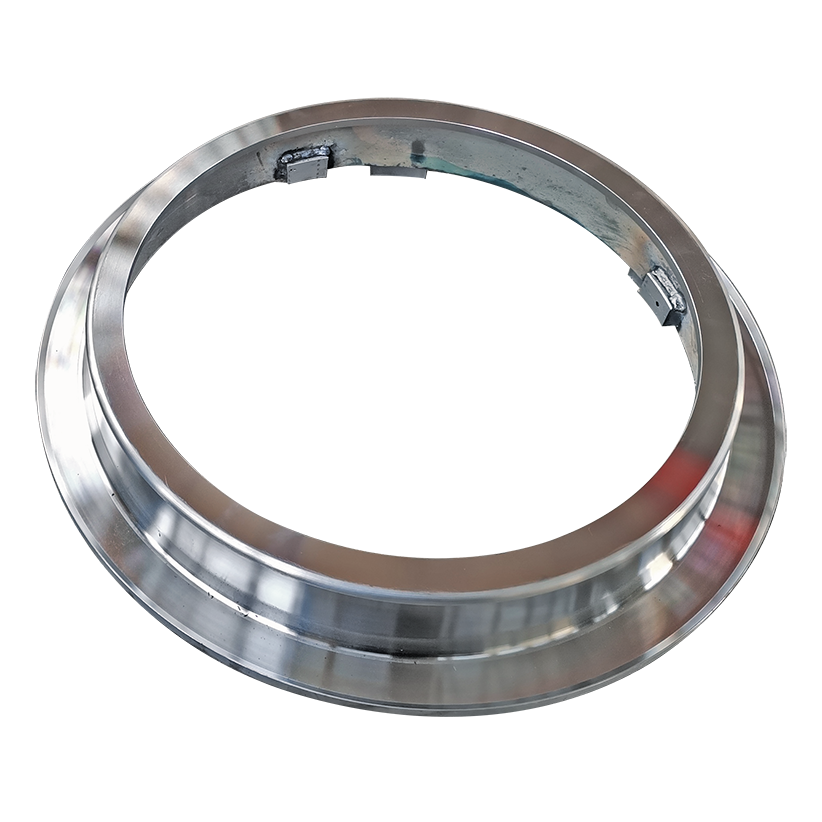

Ductile iron casting has emerged as a significant material in various industrial applications due to its impressive mechanical properties, versatility, and durability. As a result, ductile iron casting exporters play a crucial role in the global marketplace, connecting manufacturers with the materials needed to produce high-performance products. This article explores the importance of ductile iron casting exporters, the benefits of ductile iron, and the implications for international trade.

Understanding Ductile Iron Casting

Ductile iron, also known as nodular cast iron or spheroidal graphite iron, is known for its remarkable tensile strength, ductility, and impact resistance. The unique microstructure of ductile iron is achieved by adding controlled amounts of magnesium during the melting process, which transforms the graphite flakes found in traditional cast iron into spherical shapes. This transformation enhances the material's mechanical properties, making it suitable for various applications, including automotive components, machinery parts, pipes, and construction materials.

The Role of Exporters in the Supply Chain

Ductile iron casting exporters serve as essential intermediaries that facilitate the movement of these materials from producing countries to markets around the world. They play a vital role in ensuring that manufacturers have access to high-quality ductile iron castings that meet specific industry standards and requirements. Exporters often work closely with foundries and manufacturers to ensure that the produced castings are tailored to the needs of their clients.

In addition to the logistical aspects of exporting, these companies also navigate the complexities of international trade regulations, tariffs, and customs processes. Their expertise in these areas helps streamline transactions and reduces the barriers for manufacturers seeking reliable sources of raw materials.

Benefits of Ductile Iron Casting

The advantages of ductile iron casting are numerous, making it a preferred choice for many industries. One of the primary benefits is its excellent combination of strength and ductility. This means that even under extreme stress, ductile iron components can endure deformation without breaking, which is critical for safety and performance in applications such as automotive and aerospace engineering.

ductile casting exporter

Furthermore, ductile iron has excellent wear resistance, corrosion resistance, and ability to withstand high temperatures. This durability extends the lifespan of components and reduces maintenance costs, making it a cost-effective solution in the long run. Additionally, ductile iron castings are relatively lightweight compared to other metals with similar strength, allowing for design flexibility and ease of handling.

Implications for Global Trade

The growing demand for ductile iron casting in various sectors has significant implications for global trade. Countries that specialize in producing high-quality ductile iron components are well-positioned to capitalize on the rising demand. This creates opportunities for exporters to forge partnerships with manufacturers in different regions, enhancing economic ties and fostering growth.

Moreover, as industries increasingly focus on sustainability, the recyclability of ductile iron further enhances its appeal. Exporters can promote the use of recycled materials, aligning with global initiatives aimed at reducing carbon footprints and promoting sustainable practices.

Challenges Faced by Exporters

Despite the positive outlook, ductile iron casting exporters face several challenges in the global market. Fluctuating raw material costs, varying quality standards across countries, and geopolitical tensions can impact supply chains and pricing. To overcome these challenges, exporters must invest in quality assurance measures, develop strong relationships with suppliers, and stay informed about market trends.

Additionally, adapting to technological advancements, such as automation and digitalization in manufacturing processes, is crucial. Exporters who embrace these changes can improve efficiency and maintain a competitive edge in the market.

Conclusion

Ductile iron casting exporters are pivotal players in the global supply chain, providing essential materials to various industries. Their role in facilitating trade, ensuring quality, and navigating regulatory landscapes cannot be overstated. As the demand for ductile iron continues to rise, exporters must adapt to the evolving market and address challenges to remain competitive. With the right strategies, the ductile iron casting export sector can thrive, contributing to economic growth and innovation worldwide.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025