- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

אוק . 31, 2024 20:55 Back to list

Exploring the Properties and Applications of Eutectic Aluminum Alloys in Modern Engineering

Eutectic aluminum alloys are significant materials in the fields of engineering and manufacturing, revered for their unique properties and versatile applications. These alloys typically consist of aluminum combined with elements such as silicon, copper, magnesium, and other alloys, and they exhibit a specific microstructure that enhances their performance characteristics.

One of the most common types of eutectic aluminum alloys is the aluminum-silicon system. This alloy features a eutectic composition of approximately 12.6% silicon, which is known for its excellent fluidity during casting, making it particularly suitable for complex shapes and intricate designs. The eutectic structure forms when both aluminum and silicon solidify simultaneously, resulting in a mixture of fine silicon crystals distributed within the aluminum matrix. This microstructure imparts improved mechanical properties, such as increased strength and enhanced wear resistance. As a result, these alloys are widely utilized in the automotive and aerospace industries, where lightweight yet strong materials are essential for performance and fuel efficiency.

Another notable eutectic alloy is the aluminum-copper system. This alloy is characterized by its higher strength and better heat treatment response, making it ideal for applications requiring superior mechanical properties. Eutectic aluminum-copper alloys are commonly employed in the manufacturing of aircraft components and high-performance automotive parts. However, they may have lower corrosion resistance compared to other aluminum alloys, necessitating protective coatings or treatments.

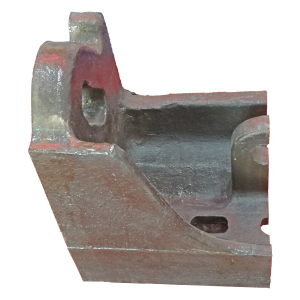

eutectic aluminum alloy

Eutectic aluminum alloys also offer advantages in casting processes. Their low shrinkage upon solidification reduces casting defects such as porosity and hot cracking, facilitating the production of high-quality castings. This reliability in casting quality contributes to their growing popularity in various sectors, including consumer electronics, machinery, and industrial applications.

In conclusion, eutectic aluminum alloys play a crucial role in modern manufacturing, providing the necessary combination of lightweight, strength, and casting ability that modern applications demand. With ongoing advancements in alloy development and processing techniques, these materials are poised to remain at the forefront of innovation, supporting a wide array of industries in their pursuit of improved performance and sustainability. As research continues, we can expect to see even more tailored properties and applications emerging from eutectic aluminum alloys.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025