- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

अक्टूबर . 05, 2024 04:46 Back to list

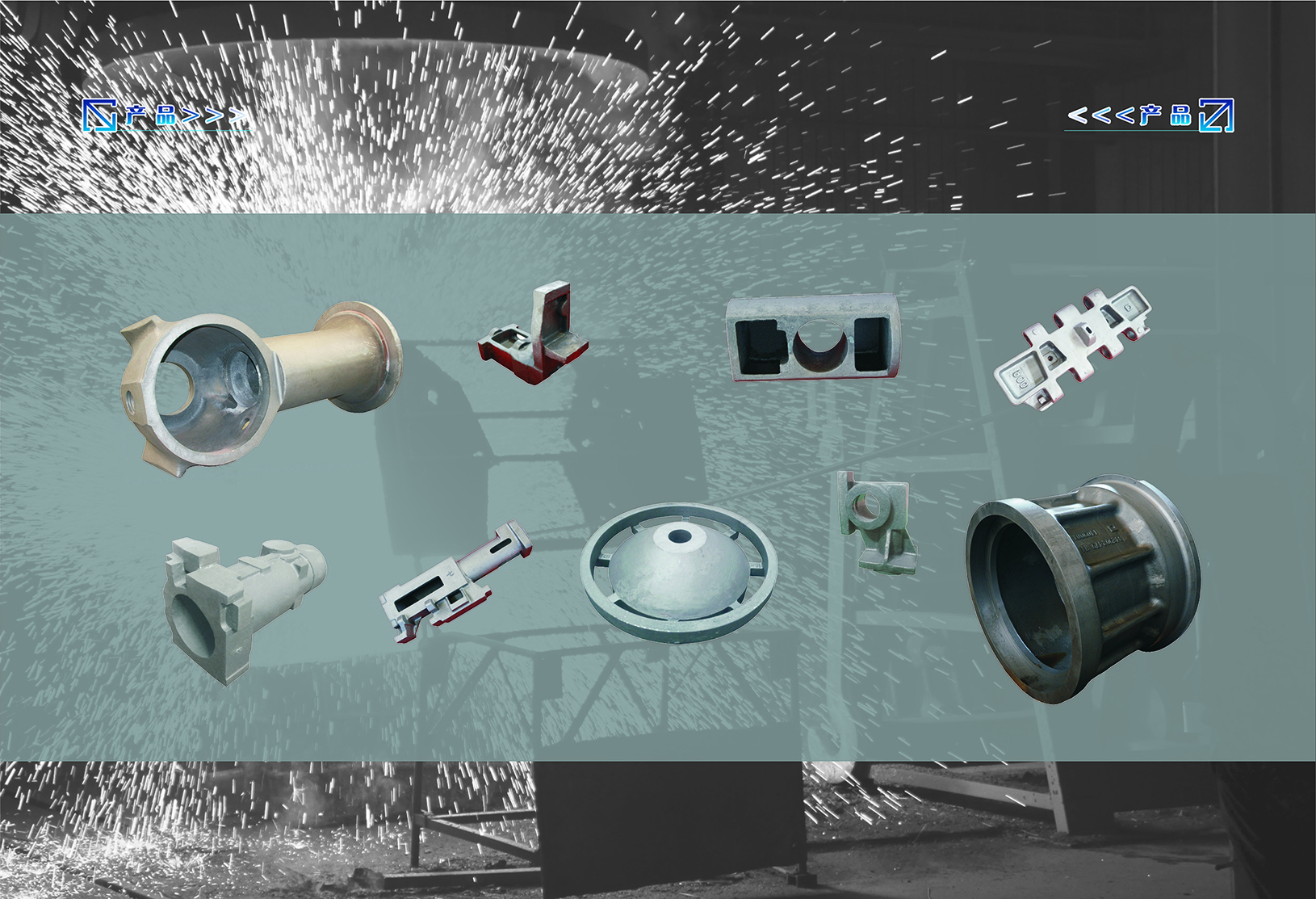

Custom Copper Sand Casting Services for Unique Industrial Applications and Prototyping Solutions

Custom Copper Sand Casting A Comprehensive Overview

Copper sand casting is a versatile manufacturing process that uses sand as a mold material to produce intricate metal parts. This technique has been employed for centuries, evolving in response to advancements in technology and materials. Among various metals, copper stands out due to its exceptional properties, including high conductivity, corrosion resistance, and excellent malleability. In this article, we will explore the intricacies of custom copper sand casting, its advantages, applications, and the step-by-step process involved.

The Advantages of Copper Sand Casting

Custom copper sand casting offers numerous benefits. Firstly, the process allows for the production of complex shapes that might be challenging or impossible to achieve through other fabrication methods. The sand molds can accommodate elaborate designs, enabling manufacturers to create unique and tailored components for specific applications.

Secondly, copper's remarkable thermal and electrical conductivity makes it ideal for various industries, including electronics, automotive, and aerospace. Components like electrical connectors, turbine parts, and heat exchangers benefit significantly from copper's properties, making custom casting a popular choice.

Furthermore, the sand casting process is relatively cost-effective for both small and large production runs. The use of sand molds allows manufacturers to create multiple castings with lower upfront costs compared to other methods like die casting. This flexibility is particularly advantageous for businesses that require custom parts in varying quantities.

The Sand Casting Process

The custom copper sand casting process consists of several key steps

custom copper sand casting

1. Design and Pattern Making The first step involves creating a detailed design of the part. A pattern, usually made from wood or metal, is then fabricated to form the mold in which the copper will be poured. The accuracy of the pattern significantly impacts the final product's dimensions and shapes.

2. Mold Preparation The pattern is placed in a flask, and sand mixed with a bonding agent is packed around it. Once the sand is compacted, the pattern is removed, leaving a hollow cavity that mirrors the desired shape of the copper part.

3. Melting and Pouring Copper ingots are heated to their melting point, typically around 1,984°F (1,085°C). The molten copper is then poured into the sand molds. Care is taken to prevent defects, such as inclusions or air pockets, during this critical phase.

4. Cooling and Finishing After pouring, the molten copper cools and solidifies. Once cooled, the sand mold is broken away to reveal the cast part. The final part often requires additional finishing processes, such as machining, polishing, or surface treatment, to ensure it meets the desired specifications.

5. Quality Control Custom copper sand castings undergo rigorous quality checks to ensure they meet industry standards and customer requirements. This includes dimensional inspections, surface quality evaluations, and testing for mechanical properties.

Applications of Custom Copper Sand Castings

Custom copper sand castings are used in a wide range of applications across various industries. In the electrical sector, components like transformers, circuit breakers, and connectors are often cast from copper due to its excellent electrical conductivity. In the automotive industry, parts such as engine block components and brake systems benefit from the durability and heat resistance of copper castings.

In summary, custom copper sand casting is a highly effective manufacturing process that combines the advantages of copper with the flexibility of sand casting. This technique not only meets the specific requirements of various industries but also offers cost-effective solutions for producing high-quality, complex metal components. As technology advances, custom copper sand casting is likely to remain a vital part of modern manufacturing.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025