- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

अक्टूबर . 19, 2024 02:55 Back to list

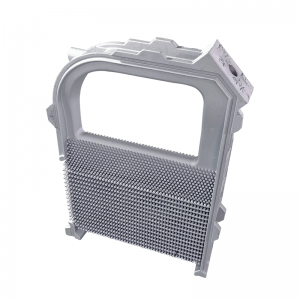

custom ductile iron pipe mold bottom ring

Custom Ductile Iron Pipe Mold Bottom Ring Innovation in Pipe Manufacturing

In the world of pipe manufacturing, the quality and efficiency of the molds used are paramount. One critical component of these molds is the bottom ring, particularly in the production of ductile iron pipes. Custom ductile iron pipe mold bottom rings have become essential for manufacturers seeking to enhance their production processes and ensure the highest quality of their products.

Ductile iron, known for its impressive strength and durability, is increasingly favored over traditional cast iron in various industrial applications. The design of the bottom ring is crucial, as it directly affects the molding process and the final properties of the pipe. A custom bottom ring can be tailored to meet specific requirements, enhancing the mold's performance and longevity.

One of the key advantages of custom molds is the ability to optimize the cooling rates during the casting process. By carefully designing the bottom ring, manufacturers can achieve uniform cooling, which is essential for reducing defects such as porosity and ensuring a consistent wall thickness. This level of precision is vital, as it directly influences the mechanical properties of the finished ductile iron pipes, making them more resilient and reliable in demanding applications.

custom ductile iron pipe mold bottom ring

Moreover, a well-designed bottom ring can significantly improve the efficiency of the manufacturing process. Custom solutions often lead to faster production times and reduced scrap rates, ultimately lowering operational costs. Innovations such as advanced materials and design software allow manufacturers to create bottom rings that not only meet but exceed industry standards.

Additionally, the versatility of custom ductile iron pipe mold bottom rings enables manufacturers to cater to a diverse range of specifications. Whether the need is for large diameter pipes for water transmission or smaller pipes for industrial applications, custom solutions ensure that manufacturers can adapt to the changing market demands swiftly.

Furthermore, as sustainability becomes increasingly important in manufacturing, creating efficient molds that minimize waste is essential. Custom bottom rings that optimize the molten metal flow can help in achieving fewer pour-offs and reduce material waste. This not only benefits the environment but also aligns with the industry's push toward more sustainable practices.

In conclusion, custom ductile iron pipe mold bottom rings play a vital role in modern pipe manufacturing. Their ability to enhance production efficiency, improve product quality, and meet varying market demands makes them an indispensable asset for manufacturers. As technology continues to evolve, the importance of innovation in mold design will only grow, shaping the future of the ductile iron pipe industry.

-

High-Precision Colloidal Silica Casting Solutions Custom & ODM

NewsMay.20,2025

-

High-Efficiency Cast Silico Aluminum Gas Boiler ODM & Custom Solutions

NewsMay.20,2025

-

Steel Reinforced Concrete Pipe Bottom Ring Moulds Buy Custom Solutions

NewsMay.19,2025

-

Original Concrete Pipe Mold Bottom Ring & Pallet Chinese Factory Direct Sale

NewsMay.19,2025

-

Custom Room Heating Heat Exchangers Energy-Efficient Solutions

NewsMay.18,2025

-

Precision Milling Body Casting Solutions Custom & ODM Options

NewsMay.18,2025