- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

अक्टूबर . 02, 2024 03:38 Back to list

Custom Pipe Mould Pallet for Efficient Punching and Production Solutions

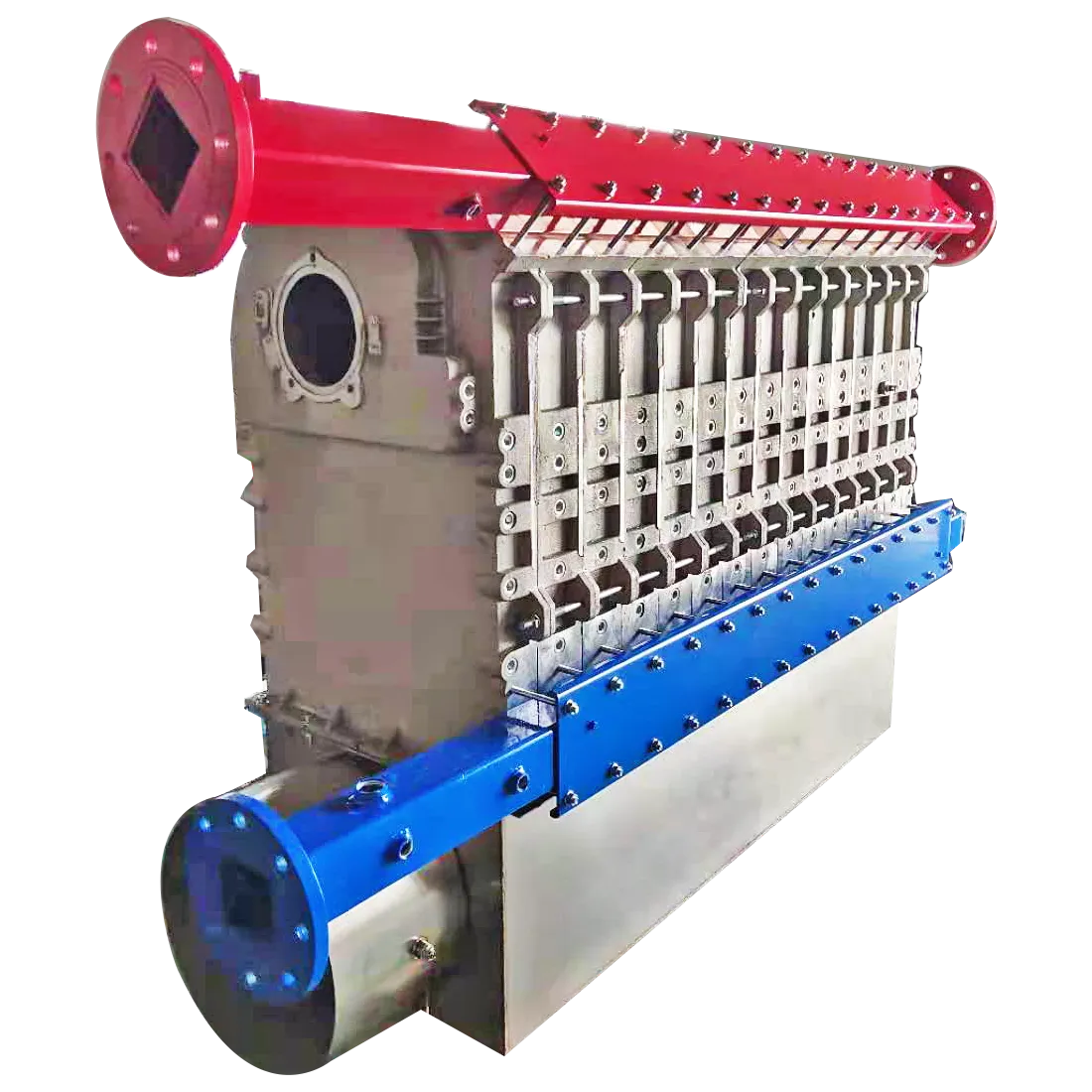

Custom Punching Pipe Mould Pallet Innovations in Manufacturing

In the ever-evolving landscape of manufacturing, the need for precision and efficiency has never been more pronounced. One of the standout innovations that capture this demand is the custom punching pipe mould pallet. This specialized equipment not only streamlines the manufacturing process but also enhances product quality, enables flexibility in design, and ultimately reduces production costs.

Understanding Pipe Moulds

Pipe moulds are essential components in the production of various pipes used across industries, including construction, automotive, and plumbing. Traditional methods of pipe manufacturing often involve labor-intensive processes that may lead to inconsistencies and waste. However, with the introduction of custom punching pipe mould pallets, manufacturers can achieve a higher degree of precision and repeatability.

A punching pipe mould pallet is a specially designed fixture that holds the pipe mould in place during the manufacturing process. The custom aspect of these pallets means that they can be tailored to fit specific mould dimensions and requirements, accommodating a wide range of pipe sizes and shapes. This customization is crucial for industries that require specific designs for unique applications.

Benefits of Customization

The primary advantage of using a custom punching pipe mould pallet is the ability to cater to individual client needs. Different industries and projects may require pipes of varying dimensions, pressures, and materials. Custom pallets allow manufacturers to quickly adapt their production capabilities to meet these diverse requirements, significantly reducing lead times.

Moreover, custom mould pallets contribute to reducing scrap rates. Traditional moulding methods often result in wasted materials due to discrepancies between the mould and the final product. By ensuring that the moulds are accurately held in place, custom pallets minimize the risk of errors, resulting in higher yield and lower material costs.

Improving Efficiency

custom punching pipe mould pallet

Efficiency is a key factor in modern manufacturing. Custom punching pipe mould pallets help improve operational efficiencies during the moulding process. They provide stability, allowing for faster production speeds while maintaining high levels of accuracy. Operators spend less time adjusting or realigning inserts, which enhances overall productivity.

Additionally, innovative design features such as quick-release mechanisms and integrated guiding systems in these pallets facilitate faster changeovers between different pipe designs. This adaptability allows manufacturers to swiftly transition between production runs, ensuring they can respond to market demands without significant downtime.

Quality Assurance

Quality is paramount in pipe manufacturing, particularly in sectors where safety and integrity are critical. The use of custom punching pipe mould pallets enhances quality control by ensuring that each mould is perfectly aligned and securely held during the moulding process. This alignment is crucial, as even minor discrepancies can lead to defects in the final product.

Furthermore, with the growth of smart manufacturing technologies, some custom pallets are now equipped with sensors that monitor key parameters in real time. This integration of technology allows manufacturers to proactively identify any deviations from set specifications, quickly addressing issues before they result in defective products.

Sustainability Considerations

As industries are increasingly shifting towards more sustainable practices, the custom punching pipe mould pallet also plays a role in reducing the environmental footprint of manufacturing. By optimizing material use, lowering scrap rates, and improving overall efficiency, these pallets contribute to more sustainable manufacturing processes. Companies can meet their production targets without excessive waste, aligning with global sustainability goals.

Conclusion

The rise of custom punching pipe mould pallets marks a significant advancement in manufacturing technology. By providing tailored solutions that enhance efficiency, improve quality, and support sustainable practices, these pallets are transforming how pipes are produced. As industries continue to demand greater precision and faster production times, the importance of innovation in tools and processes like custom punching pipe mould pallets will only grow, shaping the future of manufacturing.

-

Custom Room Heating Heat Exchangers Energy-Efficient Solutions

NewsMay.18,2025

-

Precision Milling Body Casting Solutions Custom & ODM Options

NewsMay.18,2025

-

Custom Cast Silicon Aluminum Heat Exchanger for Hot Water Boiler High Efficiency

NewsMay.18,2025

-

Premium Custom & ODM Vehicle Parts Bulk Order Deals

NewsMay.17,2025

-

Custom Commercial Hot Water Heat Exchangers High-Efficiency Solutions

NewsMay.17,2025

-

Custom Fibre Reinforced Concrete Pipe Bottom Ring Moulds – Buy Durable Solutions

NewsMay.17,2025