- Neeg African

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Tuam Tshoj

- Tuam Tshoj (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Lus Askiv

- Esperanto

- Estonian

- Finnish

- Fabkis

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- haus

- hawaiian

- Hebrew

- Tsis yog

- Miao

- Hungarian

- Icelandic

- ib igbo

- Indonesian

- irish

- Italian

- Nyiv

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandan

- Kauslim

- Kurdish

- Kyrgyz

- Labor

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Lavxias

- Samoan

- Scottish Gaelic

- Serbian

- Lus Askiv

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thaib

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Nyab Laj

- Welsh

- Pab

- Yiddish

- Yoruba

- Zulu

Jun . 09, 2025 15:46 Rov qab mus rau npe

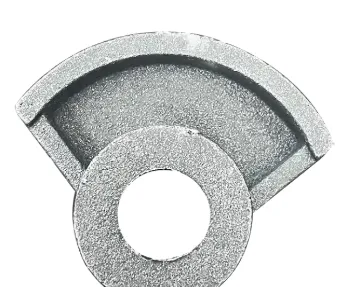

Ductile Casting Innovations

The ductile casting industry has seen remarkable advancements in recent years, particularly in sand castings and sand cast techniques. These innovations have improved efficiency, durability, and cost-effectiveness in producing high-quality ductile iron components. From automated molding systems to eco-friendly sand reclamation, the latest developments are reshaping the future of metal casting. This article explores key innovations in ductile casting, focusing on sand castings and their impact on manufacturing.Let's learn about ductile casting and sand castings together!

The Evolution of Ductile Casting in Sand Castings

Ductile casting has undergone significant transformations, especially in sand castings, where traditional methods have been refined for better performance. Historically, sand cast processes relied on manual labor and basic molding techniques, leading to inconsistencies. Today, computer-aided design (CAD) and simulation software allow for precise mold creation, reducing defects and improving mechanical properties.

One major innovation is the use of 3D-printed sand molds, which enable complex geometries without the need for pattern tooling. Additionally, improved binder systems in sand castings enhance mold strength and reduce gas-related defects in ductile casting. These advancements ensure higher-quality castings with superior fatigue resistance and dimensional accuracy.

Enhancing Efficiency in Sand Cast Production is importent

Efficiency is a critical factor in modern sand cast manufacturing. Foundries are adopting automated molding systems that accelerate production while maintaining consistency. Robotic pouring systems and real-time monitoring ensure optimal metal flow and solidification in ductile casting, minimizing scrap rates.

Another breakthrough is the use of eco-friendly sand reclamation systems, which recycle used sand for repeated sand castings. This not only reduces waste but also lowers production costs. Furthermore, advanced cooling techniques, such as controlled air quenching, improve the microstructure of ductile iron, enhancing its mechanical properties.

It can be seen from this that improving the production efficiency of sand casting is useful.

The Role of Material Science in Ductile Casting

Material innovations have played a pivotal role in advancing ductile casting. Alloy modifications, such as the addition of rare earth elements, improve nodular graphite formation in sand castings, resulting in stronger and more ductile iron.

New coating technologies for sand cast molds also prevent metal penetration and improve surface finish. Additionally, developments in heat treatment processes, such as austempering, enhance the toughness and wear resistance of ductile iron components. These innovations ensure that sand castings meet the demanding requirements of industries like automotive, construction, and heavy machinery.

Sustainability in Sand Castings for Ductile Iron

Sustainability is a growing priority in ductile casting, and sand castings are at the forefront of eco-friendly foundry practices. Manufacturers are adopting biodegradable binders and low-emission sand additives to reduce environmental impact.

Energy-efficient melting furnaces and waste heat recovery systems further minimize the carbon footprint of sand cast production. Moreover, closed-loop water systems and dust collection technologies ensure cleaner operations. These sustainable practices not only comply with regulations but also appeal to environmentally conscious customers.

FAQs about Ductile Casting and Sand Cast Innovations

What are the key advantages of ductile casting over traditional methods?

Ductile casting offers superior strength, flexibility, and impact resistance compared to gray iron. Innovations in sand castings further enhance these properties by improving mold precision and reducing defects.

How does 3D printing improve sand cast production?

3D-printed sand molds eliminate the need for physical patterns, allowing for faster prototyping and complex geometries. This technology reduces lead times and costs in ductile casting.

What are the common defects in sand castings, and how can they be prevented?

Common defects include porosity, shrinkage, and sand inclusions. Using high-quality binders, proper gating design, and simulation software can minimize these issues in sand cast processes.

How does heat treatment affect the properties of ductile casting ?

Heat treatment processes like austempering enhance the strength and ductility of ductile iron, making it suitable for high-stress applications in sand castings.

What sustainable practices are used in modern sand cast manufacturers?

Eco-friendly binders, sand reclamation, and energy-efficient furnaces are key sustainable practices in sand cast production, reducing waste and emissions in ductile casting.

The future of ductile casting lies in continuous innovation, particularly in sand castings, where automation, material science, and sustainability are driving progress. Whether you're in construction, automotive, or industrial manufacturing, upgrading to advanced sand cast techniques can give you a competitive edge.As foundries adopt smarter technologies, sand cast production will become even more efficient, precise, and environmentally friendly. By staying ahead of these trends, manufacturers can deliver superior ductile iron components for diverse industrial applications.

Don’t get left behind—invest in useful ductile casting solutions today! By adopting these innovations, businesses can achieve higher productivity, lower costs, and superior product performance. The future of metal casting is here—make sure you’re part of it.We are waiting for your purchase. Don't hesitate any longer. Please trust us!We will definitely bring you a different kind of service to satisfy you.

-

The Ultimate Choice for Optimal Thermal Exchange: Hex Heat Exchangers

Xov xwmJun.24,2025

-

Hydronic Gas Boiler: The Efficient Heating Solution For Your Needs

Xov xwmJun.24,2025

-

Discover the Efficiency of Mini Boiler Gas

Xov xwmJun.24,2025

-

Concrete Pipe Mold Pallet Solutions

Xov xwmJun.24,2025

-

Unveiling the Benefits of Light Pallet Mould

Xov xwmJun.24,2025

-

Discover the Benefits of Ductile Cast Iron Pipe Mold Pallet

Xov xwmJun.24,2025