- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Dec . 09, 2024 17:41 Back to list

Custom Concrete Pipe Mold Pallet Solutions for Efficient Production and Durability

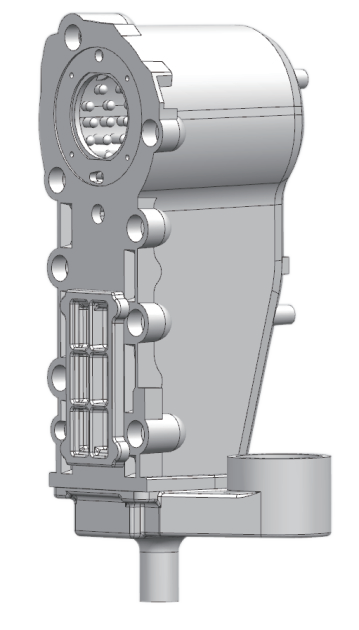

OEM Concrete Pipe Mold Pallet A Comprehensive Overview

In the world of construction and infrastructure, concrete pipes play a vital role in various applications such as drainage systems, sewer lines, and water transportation. To produce these essential components efficiently, OEM (Original Equipment Manufacturer) concrete pipe mold pallets are increasingly becoming a crucial element in the manufacturing process. This article explores the significance of OEM concrete pipe mold pallets, their manufacturing process, benefits, and the future trends in this industry.

Understanding OEM Concrete Pipe Mold Pallets

OEM concrete pipe mold pallets are specialized equipment designed for the production of concrete pipes of various sizes and shapes. These pallets serve as formwork for casting concrete, ensuring that the finished pipes adhere to specific standards of durability and dimensional accuracy. By partnering with OEM manufacturers, companies can acquire customized solutions tailored to their unique specifications, leading to enhanced production efficiency and product quality.

Manufacturing Process

The process of producing concrete pipes using OEM mold pallets typically starts with the design phase. Manufacturers work closely with clients to understand their requirements, including the pipe dimensions, strength, and application. This collaboration often involves advanced software that allows for precise modeling of the mold pallets.

Once the design is finalized, the production phase begins, usually involving high-quality materials like steel or fiberglass for the mold pallets. These materials are selected to withstand the harsh conditions of concrete casting, including high pressure and heavy loads. The pallets are then manufactured using advanced techniques like CNC machining, ensuring high precision and durability.

After the mold pallets are produced, they undergo rigorous quality control tests to ensure they meet industry standards. Only after passing these tests are they delivered to clients, ready for use in the concrete pipe production process.

oem concrete pipe mold pallet

Benefits of Using OEM Mold Pallets

1. Customization One of the significant advantages of OEM concrete pipe mold pallets is customization. Manufacturers can tailor the pallets to meet specific project requirements, ensuring that the final products align perfectly with client expectations.

2. Durability OEM manufacturers use high-quality materials and advanced production techniques, resulting in mold pallets that are not only robust but also resistant to wear and tear. This longevity reduces the need for frequent replacements, ultimately leading to lower operational costs.

3. Efficiency Custom OEM pallets are designed for optimal production efficiency. They enable faster casting and curing processes, which can significantly boost overall productivity in concrete pipe manufacturing.

4. Quality Assurance By utilizing OEM solutions, companies can adhere to stringent quality standards. Consistent size and shape achieved through high-quality molds enhance the reliability of concrete pipes, which is vital for safety and performance in infrastructure applications.

Future Trends

As the construction industry continues to evolve, so too will the demand for innovative solutions in concrete pipe manufacturing. Emerging technologies such as 3D printing and automation are poised to revolutionize the production of OEM concrete pipe mold pallets. This shift promises to enhance efficiency further, reduce labor costs, and improve overall product quality. Furthermore, increasing sustainability concerns may lead manufacturers to explore eco-friendly materials and processes, aligning with global efforts to reduce the carbon footprint in construction.

In conclusion, OEM concrete pipe mold pallets represent a critical innovation in the construction industry, offering customized, durable, and efficient solutions for producing high-quality concrete pipes. As technological advancements continue to reshape the manufacturing landscape, the importance of these mold pallets will only grow, paving the way for enhanced infrastructure development in the future.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025