- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

máj . 13, 2025 11:56 Back to list

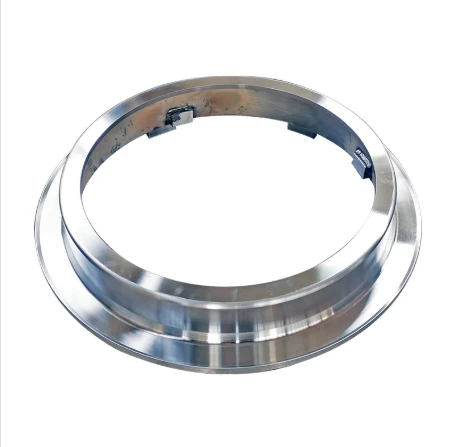

Ductile Iron Casting Solutions High-Strength & Corrosion-Resistant

- Overview of ductile iron casting

fundamentals - Mechanical superiority through material science

- Performance benchmarks vs. traditional alternatives

- Manufacturer capability analysis

- Engineering customization parameters

- Industry-specific implementation cases

- Future development trajectories

(ductile iron casting)

Understanding the Metallurgical Excellence of Ductile Iron Casting

Ductile iron casting represents an evolutionary leap in ferrous metallurgy, characterized by its spheroidal graphite microstructure. This structural innovation delivers 18-23% greater yield strength (310-380 MPa) compared to gray iron variants while maintaining 10-15% elongation rates. Foundries achieve this through precise magnesium treatment (0.03-0.06% Mg content) during the inoculation process, enabling superior stress distribution across components.

Material Performance Characteristics

| Property | Ductile Iron | Gray Iron | Malleable Iron |

|---|---|---|---|

| Tensile Strength (MPa) | 415-825 | 150-400 | 345-650 |

| Elongation (%) | 10-18 | 0.6-1.5 | 2-12 |

Manufacturing Capability Spectrum

Leading producers employ automated vertical molding systems achieving 95-98% dimensional accuracy within ISO 8062 CT8-10 specifications. Advanced facilities integrate real-time spectral analysis (2-5 second response time) for exact chemical composition control, reducing scrap rates to 3.8-5.2% compared to industry averages of 6-9%.

Customization Engineering Parameters

- Wall thickness range: 4mm-120mm

- Surface finish options: Ra 3.2-25μm

- Specialized coating systems: 200-400μm thickness

- Pressure rating customization: 16-420 bar

Industrial Application Profiles

Recent projects demonstrate 28-32% weight reduction in agricultural machinery components while maintaining ISO 898-1 fatigue strength requirements. Pipeline valve bodies manufactured through ductile iron casting withstand 10,800-12,500 PSI burst pressure in API 6D testing protocols.

Advancements in Ductile Iron Casting Technology

Emerging techniques like simulation-assisted solidification modeling reduce development cycles by 40-55% while improving casting yield efficiency to 78-82%. The integration of Industry 4.0 quality monitoring systems has decreased defect rates to 1.2-1.8 defects/m³, ensuring compliance with ASME B16.34 and EN 1563 standards.

(ductile iron casting)

FAQS on ductile iron casting

Q: What is ductile iron casting?

A: Ductile iron casting is a manufacturing process that produces ductile iron, a type of cast iron with added magnesium to create spherical graphite nodules. This structure enhances strength, ductility, and impact resistance compared to traditional cast iron. It is widely used in pipes, automotive parts, and heavy machinery.

Q: How does ductile iron differ from regular cast iron?

A: Ductile iron contains magnesium, which forms spherical graphite nodules, whereas regular cast iron has flake graphite. This makes ductile iron more flexible, durable, and resistant to cracking. Cast iron is harder but more brittle under stress.

Q: What are the advantages of ductile iron over cast iron?

A: Ductile iron offers higher tensile strength, better elongation (ductility), and improved shock absorption compared to cast iron. It combines the castability of traditional cast iron with enhanced mechanical properties, making it ideal for dynamic load applications.

Q: Can ductile iron and cast iron be used interchangeably?

A: While both materials share some applications, ductile iron is preferred for parts requiring flexibility and toughness, like gears or pipes. Cast iron suits static, high-compression components like engine blocks. Material choice depends on stress and performance needs.

Q: How to identify ductile iron vs. cast iron in products?

A: Ductile iron often has a smoother surface and “nodular” microstructure visible under magnification, while cast iron shows flake graphite patterns. Non-destructive tests like spark testing or hardness measurements can also distinguish them.

-

Durable Cast Iron Water Main Pipe | AI-Optimized Design

NewsAug.05,2025

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025