Ahụ Hammer maka Ngwuputa Ngwuputa, Emere na Steel Pụrụ Iche, Emere na China

Nkọwa

Manganese-silicon alloy cast steel hammer body.The manganese-silicon alloy casting hammer has the highest hardness and is a high-quality wear-resistant material. The hammer head has high hardness and the hammer handle has high toughness. It has been widely used in most crushers. Especially suitable for crushing high hardness materials, such as stone.

Our factory have two production lines. One is VRH molding production line, the other is resin sand production line. We use computer simulation software on the casting technology design which can simulate the casting process with quickly,accurately, comprehensively. The main smelting equipment is electric arc furnace,intermediate frequency furnace, LF refining furnace.The heating equipment is trolley heating treatment furnace, gas heating treatment furnace, all the heat treatment furnace is controlled by computer.

So we can produce various steel castings, especially the large size steel castings.

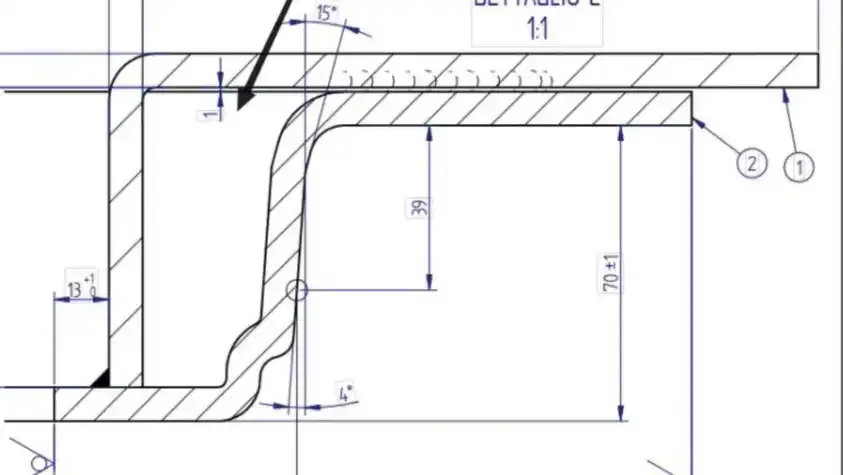

After we received detailed drawings, we will study it very carefully, understanding all technical requirements, and then we will work out a proper producing process, then we will use professional casting software to simulate the producing process on computer, till we think there is no any problem, and then we put it into production.The finished steel casting has no casting defect.

If you have the requirement of steel casting, pls send us your drawings, we will produce a qualified products for you.

A brief introduction of casting technology

Sand casting: a casting method for producing castings in sand. Steel, iron and most non-ferrous alloy castings can be obtained by sand casting methods. Process flow: sand casting process. Technical features: 1. Suitable for making blanks with complex shapes, especially with complex cavities; 2. Wide adaptability and low cost; 3. For some materials with poor plasticity, such as cast iron Etc., sand casting is the only forming process for manufacturing its parts or blanks. Application: automobile engine cylinder block, cylinder head, crankshaft and other castings

Brief Introduction of Our Foundry

|

|

||

|

Smelting Section |

Sand Regeneration System |

Intermediate Frequency Furnace |